Cefoperazone sodium and tazobactam sodium pharmaceutical composition for injection

A technology of tazobactam sodium and cefoperazone sodium, which is applied in the field of medicine, can solve the problems of restricting large-scale production of preparations, poor long-term storage stability, and potential safety hazards in clinical treatment, and achieves good effectiveness and safety, low related substances, and low degradation little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

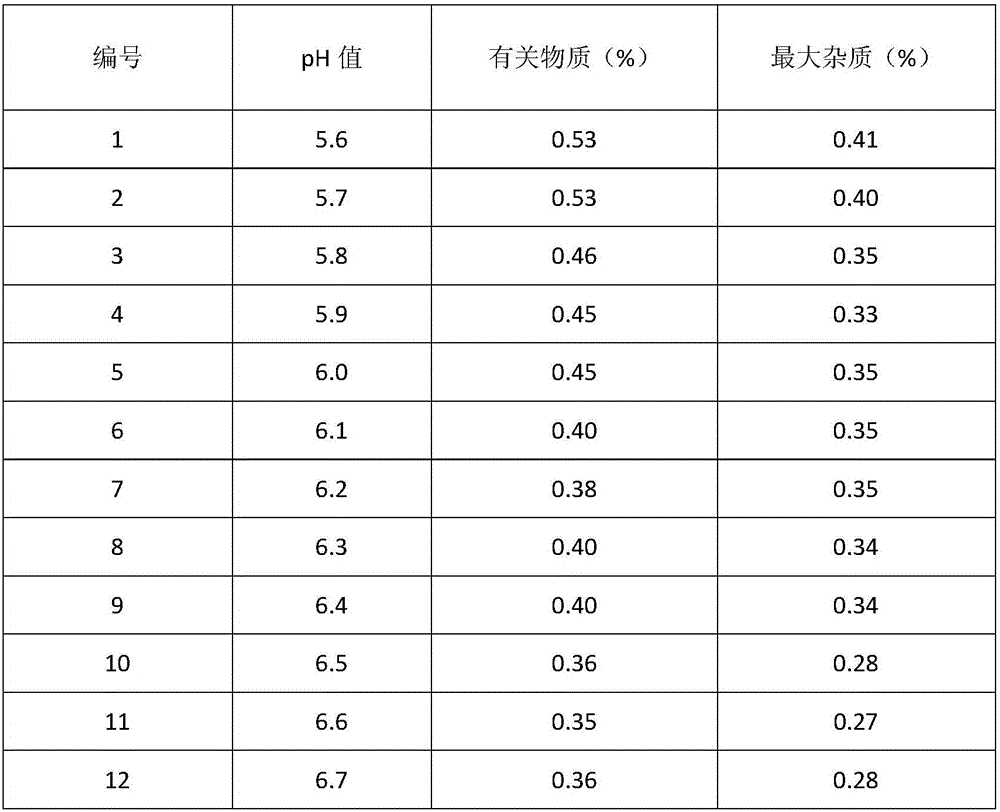

Method used

Image

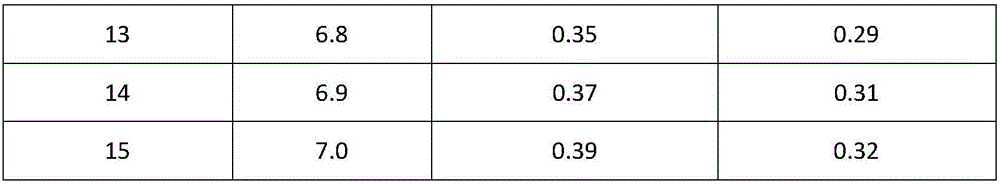

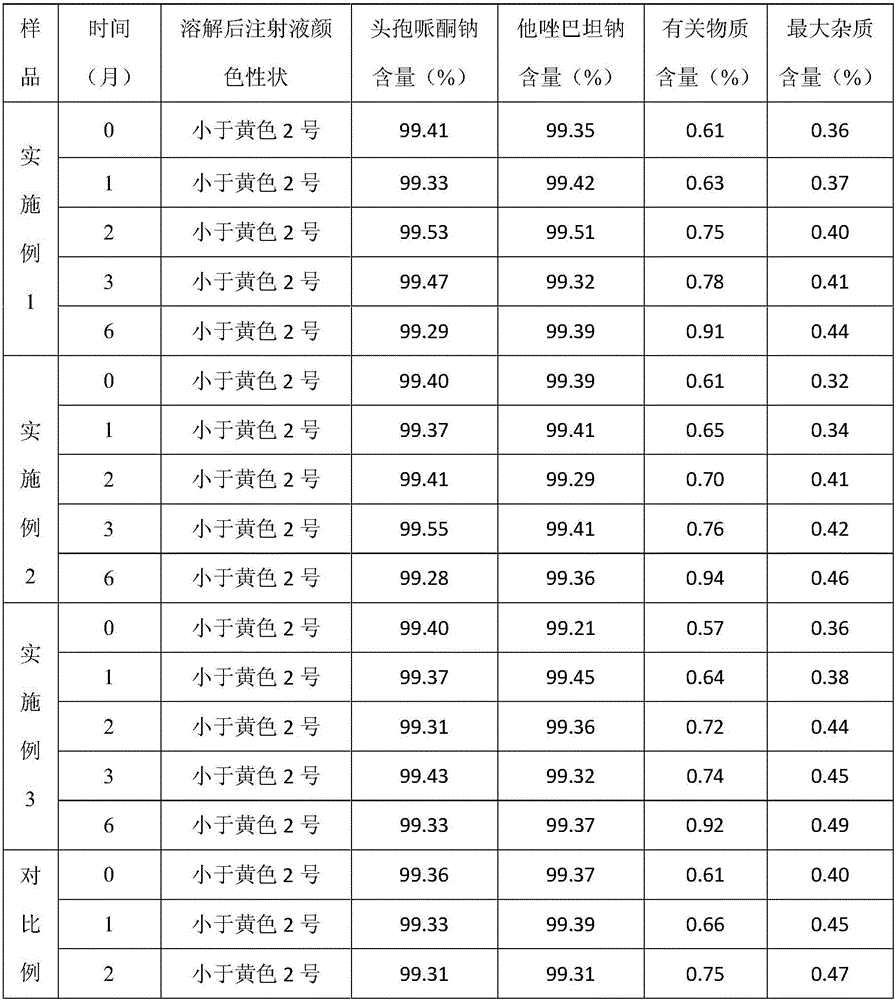

Examples

Embodiment 1

[0038] prescription:

[0039] Cefoperazone sodium 120kg (calculated as free cefoperazone)

[0040] Tazobactam sodium 30kg (calculated as free tazobactam)

[0041] Preparation:

[0042] (1) Refining of Tazobactam

[0043] Add the prescribed amount of tazobactam into the reaction kettle, add water, turn on the stirring and cooling device, and when the temperature reaches 0-5°C, add 8kg of sodium bicarbonate to adjust the pH to 6.2, and add 2Kg of neutral alumina to the reaction solution , stirred for 30 minutes, filtered, and the filtrate was neutralized with concentrated hydrochloric acid at 0-5°C until the pH was 1.5, a large amount of white crystals were precipitated, continued to stir for 2 hours, filtered, washed the filter cake with 0-5°C water for injection, and the filter cake was placed in Vacuum drying at around 45°C yields refined tazobactam.

[0044] (2) Preparation of Tazobactam Sodium

[0045] Add 64Kg of water for injection at 7-10°C to the reaction kettle, f...

Embodiment 2

[0050] prescription:

[0051] Cefoperazone sodium 120kg (calculated as free cefoperazone)

[0052] Tazobactam sodium 30kg (calculated as free tazobactam)

[0053] Preparation:

[0054] (1) Refining of Tazobactam

[0055] Add the prescribed amount of tazobactam into the reaction kettle, add water, turn on the stirring and cooling device, and when the temperature reaches 0-5°C, add 8kg of sodium bicarbonate to adjust the pH to 5.7, and add 2Kg of neutral alumina to the reaction solution , stirred for 30 minutes, filtered, and the filtrate was neutralized with concentrated hydrochloric acid at 0-5°C until the pH was 1.0, a large amount of white crystals were precipitated, continued to stir for 2 hours, filtered, washed the filter cake with 0-5°C water for injection, and the filter cake was placed in Vacuum drying at around 45°C yields refined tazobactam.

[0056] (2) Preparation of Tazobactam Sodium

[0057] Add 64Kg of water for injection at 7-10°C to the reaction kettle, f...

Embodiment 3

[0062] prescription:

[0063] Cefoperazone sodium 120kg (calculated as free cefoperazone)

[0064] Tazobactam sodium 30kg (calculated as free tazobactam)

[0065] Preparation:

[0066] (1) Refining of Tazobactam

[0067] Add the prescribed amount of tazobactam into the reaction kettle, add water, turn on the stirring and cooling device, and when the temperature reaches 0-5°C, add 8kg of sodium bicarbonate to adjust the pH to 6.4, and add 2Kg of neutral alumina to the reaction solution , stirred for 30 minutes, filtered, and the filtrate was neutralized with concentrated hydrochloric acid at 0-5°C until the pH was 2.0, a large amount of white crystals were precipitated, continued to stir for 2 hours, filtered, washed the filter cake with 0-5°C water for injection, and the filter cake was placed in Vacuum drying at around 45°C yields refined tazobactam.

[0068] (2) Preparation of Tazobactam Sodium

[0069] Add 64Kg of water for injection at 7-10°C to the reaction kettle, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com