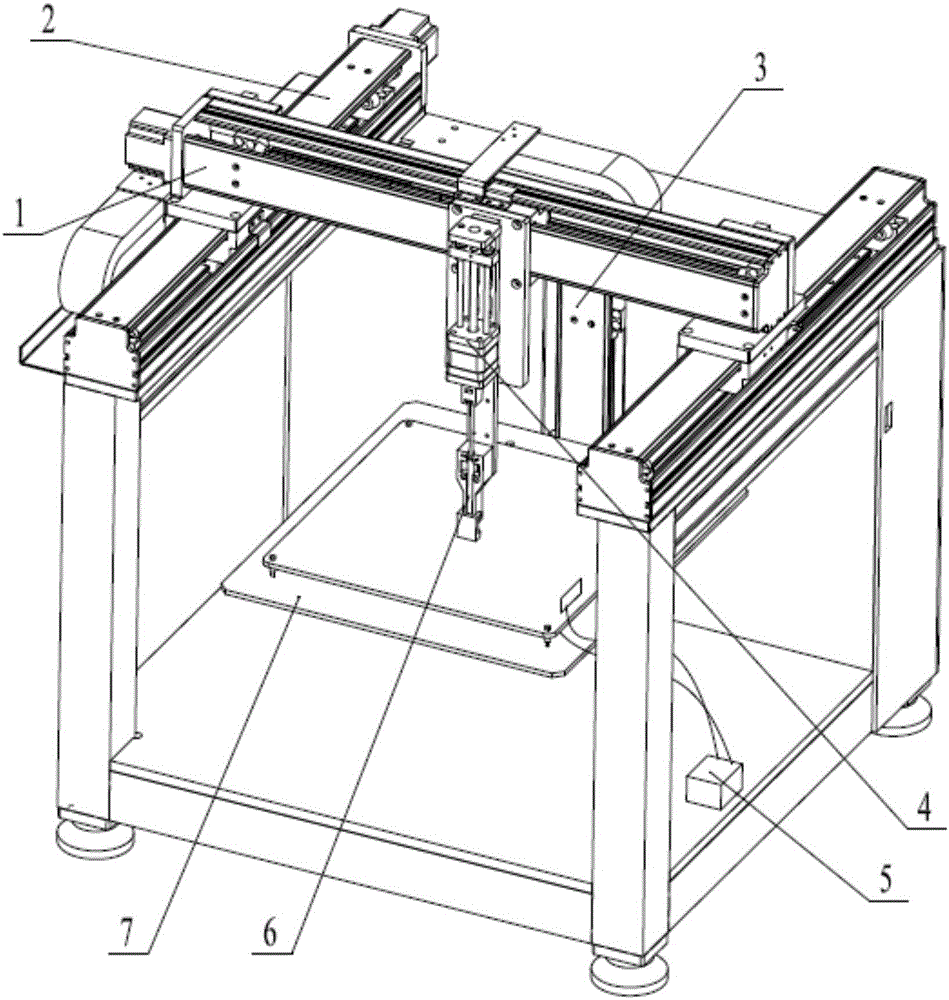

Porous bone scaffold manufacturing device and method

A technology for manufacturing devices and porous bones, which can be used in bone implants, medical science, prostheses, etc. It can solve the problems of small, uncontrollable and uncontrollable hole sizes inside the bracket, and achieve uniform and stable screw movement , Extrusion volume is precise and controllable, and the device manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] Such as Figure 8 and Figure 9Shown are the surface electron micrographs and cross-sectional electron micrographs of the porous bone scaffold manufactured by the porous bone scaffold manufacturing device of the present invention, and the bone scaffold structure of silicate powder is taken as an example to illustrate the working process of the device of the present invention:

[0074] 1) Prepare silicate powder by chemical synthesis, or directly use commercially available products, and obtain a powder with a size of 5 to 10 microns through ball milling, configure a PVA aqueous solution with a concentration of 5% to 8%, and then put the powder The body and the solution are uniformly mixed in a weight ratio of 1.4 to 1.6:1 to obtain an extrudable high-viscosity bio-ink;

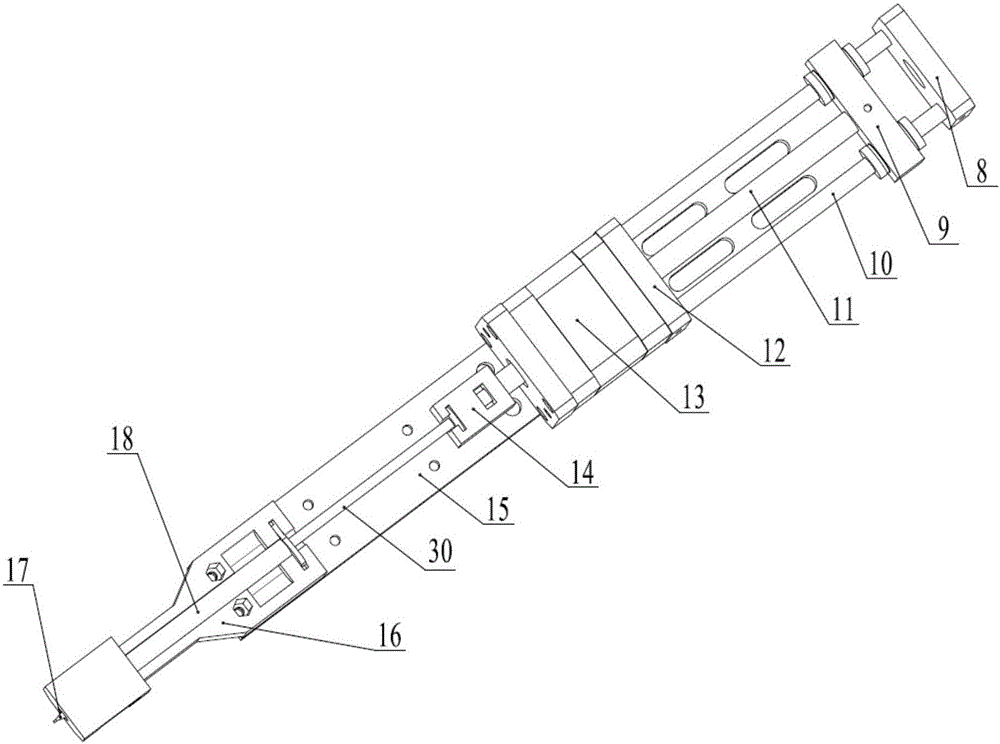

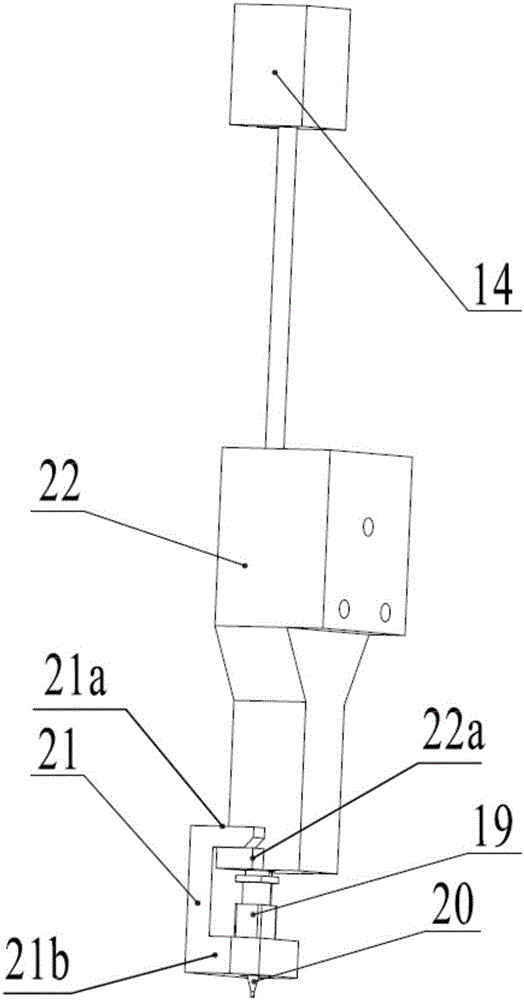

[0075] 2) Put the bio-ink obtained by the above method into the liquid storage tank 28, remove the air bubbles in the bio-ink in the liquid storage tank 28, install a linear unit 17 with a circular inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com