Treatment system for removing lead from electroplating wastewater

A technology of electroplating wastewater and treatment system, applied in metallurgical wastewater treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc. The effect of improving processing capacity, low operation and maintenance costs, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

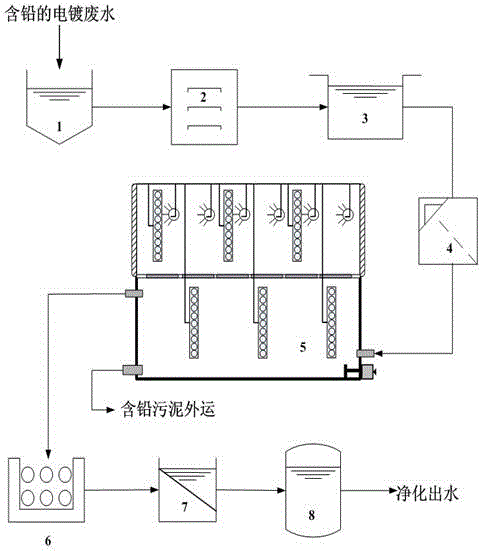

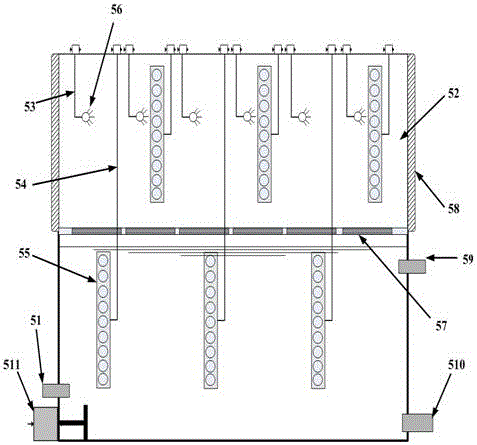

[0026] Such as figure 1The shown treatment system for removing lead in electroplating wastewater includes 1-collection well, 2-coarse grid, 3-primary sedimentation tank, 4-pH value adjustment tank, 5-biological fermentation-precipitation reaction purification system, 6 -Aerobic biological filter, 7-Secondary sedimentation tank, 8-Water purification tank, etc.; Among them, the lead-containing electroplating wastewater enters the water collection well 1 through the waste water pipeline, where centralized collection and preliminary stable adjustment are carried out, and the outlet of the water collection well 1 The coarse grid 2 is connected through the waste water pipeline, and the large-diameter solid matter in the waste water is removed here. The outlet of the coarse grid 2 is connected with the primary sedimentation tank 3 through the waste water pipeline, and the insoluble matter in the waste water is further removed here, and the primary sedimentation tank 3 The outlet is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com