Lubricating oil furfural refinement device provided with multi-stage extract recovery system and method

A furfural refining and recovery method technology, applied in the direction of lubricating compositions, etc., can solve the problems of energy consumption reduction of the recovery system and increase of energy consumption of the extraction liquid evaporation tower, and achieve low equipment investment costs, low energy consumption costs, and simple and practical processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

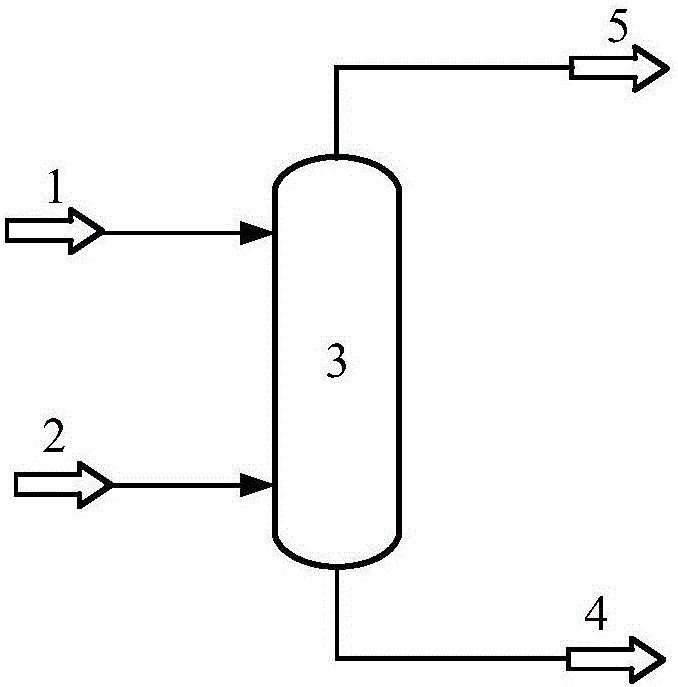

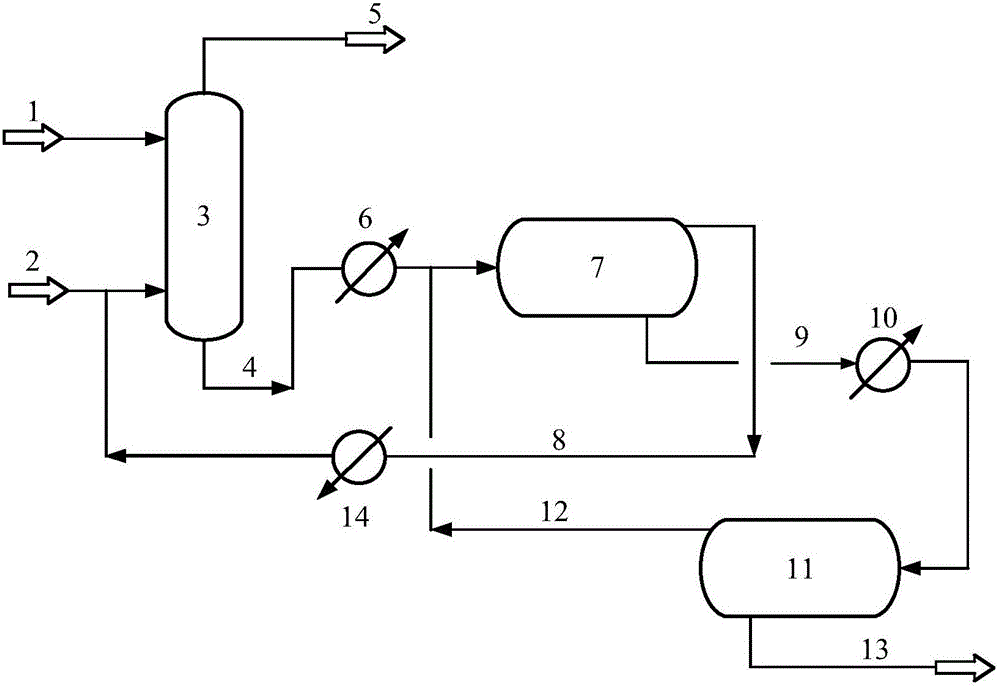

[0030] In this example, a single-tower extraction process is used to refine furfural in lubricating oil. The original process structure diagram is as follows figure 1 As shown, the process structure diagram after adding the two-stage recovery system is as follows figure 2shown. The lubricating oil is a minus-line spindle oil from a petrochemical company. Its mass average boiling point is about 360°C and its density at 20°C is 0.892g / mL. Its composition can be seen in Table 1. The flow rate of lubricating oil to be treated is 30t / h, and the equipment operating parameters and product regulations are listed in Table 1. In this example, after the lubricating oil material 2 is extracted by the extraction tower 3, the extracted liquid 4 at the bottom of the tower enters the primary cooler 6 to cool to 40°C, and then enters the primary liquid-liquid separator 7 for static phase separation, and the upper liquid phase 8 exits the primary liquid-liquid separator 7 and is heated to 80...

Embodiment 2

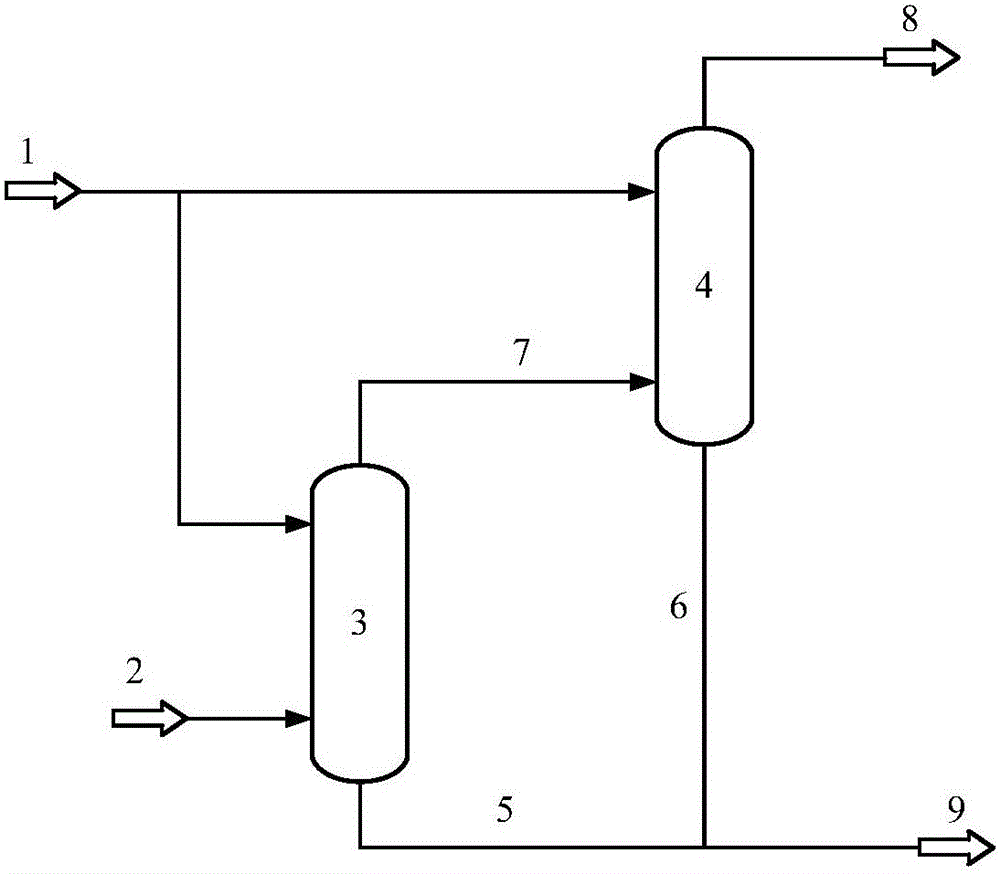

[0036] In this example, the double-tower solvent split extraction process is used to refine furfural in lubricating oil. The original process structure diagram is as follows image 3 As shown, the process structure diagram after adding the recovery system is as follows Figure 4 shown. Lubricating oil stock property is identical with the oil stock in embodiment 1. The flow rate of lubricating oil to be processed is 30t / h, and the equipment operating parameters, product regulations and accounting results are listed in Table 3. In this process, the flow ratio of furfural entering the first-stage extraction tower 3 and the second-stage extraction tower 4 is 3:1. After the lubricating oil material 2 is extracted by the extraction towers 3 and 4, the extracts 5 and 6 Mixed into the extracted liquid 9, enter the primary cooler 10 and cool to 40°C, enter the primary liquid-liquid separator 11 for static phase separation, and the upper liquid phase 12 is heated to 80°C by the heater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com