OXD-doped blue organic light-emitting device and preparation method thereof

A luminescent and electromechanical technology, applied in the direction of electrical solid devices, semiconductor/solid device manufacturing, electrical components, etc., can solve the problems of unfavorable industrial production, increase of device process cost, complicated preparation process, etc., achieve good solubility, reduce Concentration quenching effect, non-uniform dispersion phenomenon, effect of high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

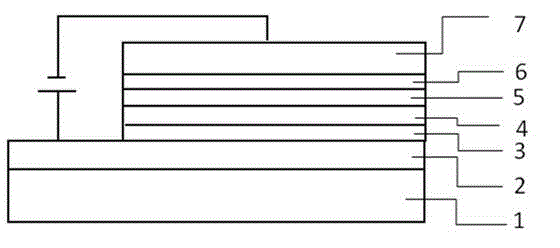

[0052] The ITO anode layer on the ITO glass is laser etched into a 50mm square electrode, and then ultrasonically cleaned with cleaning solution and deionized water for 15 minutes, and dried with high-purity nitrogen after the process is completed.

[0053] Put the dried substrate into the plasma processing chamber and vacuumize it. When the vacuum value reaches the range of 30Pa, use 150w power to treat the ITO anode with oxygen plasma for 5min.

[0054] The hole injection layer PEDOT:PSS was prepared in a clean atmospheric environment. The spin coating parameters were selected as 4000rpm, and the spin coating time was 60s. After the preparation was completed, it was placed in a nitrogen glove box for annealing at 150°C.

[0055] The light-emitting layer was spin-coated on the hole transport layer, the organic mixed host material of the light-emitting layer was PVK, OXD-7, the phosphorescent dopant material was Ph-Firpic, and the solution concentration was 15 mg / mL. The spin-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com