Multilayer-film etchant, concentrated etchant, and etching method

A technology of multilayer film and etching solution, which is applied in the field of etching solution for multilayer film, can solve problems such as blockage of etching device piping, disconnection, hole blockage of spray nozzles, etc., and achieve the effect of light environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

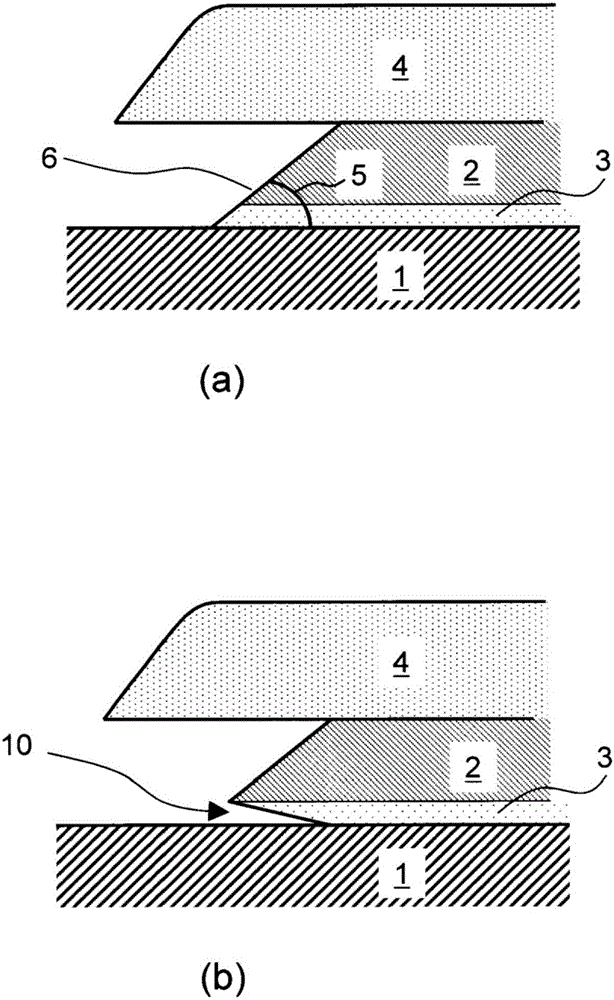

Method used

Image

Examples

Embodiment 1

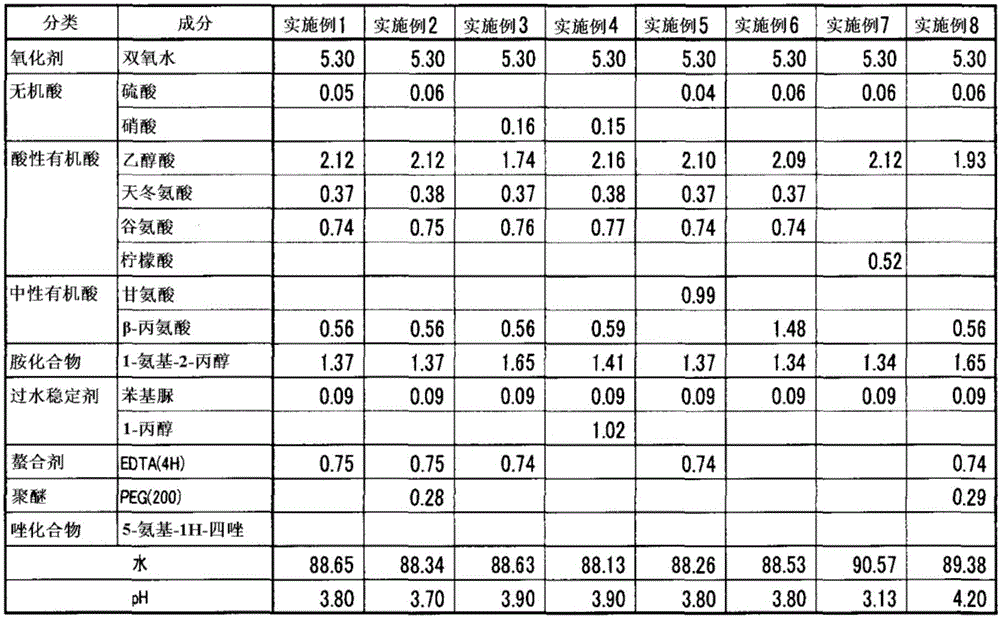

[0103] 0.06% by mass of sulfuric acid, 2.50% by mass of glycolic acid, 0.44% by mass of aspartic acid, 0.87% by mass of glutamic acid, 0.66% by mass of β-alanine, 1.61% by mass of 1-amino-2-propanol, benzene Etching solution raw materials formed by 0.11 mass % of urea and 0.88 mass % of ethylenediaminetetraacetic acid (hereinafter, also referred to as "EDTA") and 92.87 mass % of water were mixed to prepare an etching concentrate.

[0104] 35% hydrogen peroxide and the etching concentrate were mixed to prepare an etching solution having a hydrogen peroxide concentration of 5.30% by mass. Furthermore, copper sulfate was added, and it prepared so that the copper ion concentration might be 2000 ppm. In addition, it was used at a liquid temperature of 30°C. Table 1 shows the concentration of each component in the whole etching solution and the results of each evaluation item.

Embodiment 2

[0106] 0.07% by mass of sulfuric acid, 2.50% by mass of glycolic acid, 0.45% by mass of aspartic acid, 0.88% by mass of glutamic acid, 0.66% by mass of β-alanine, 1.61% by mass of 1-amino-2-propanol, benzene 0.11% by mass of urea, 0.88% by mass of ethylenediaminetetraacetic acid, and 0.33% by mass of polyethylene glycol (hereinafter also referred to as "PEG"). The raw material of the etching solution was mixed with 92.51% by mass of water to prepare an etching concentrate .

[0107] 35% hydrogen peroxide and the etching concentrate were mixed to prepare an etching solution having a hydrogen peroxide concentration of 5.30% by mass. Furthermore, copper sulfate was added, and it prepared so that the copper ion concentration might be 2000 ppm. In addition, it was used at a liquid temperature of 30°C. Table 1 shows the concentration of each component in the whole etching solution and the results of each evaluation item.

Embodiment 3

[0109] 0.19% by mass of nitric acid, 2.05% by mass of glycolic acid, 0.44% by mass of aspartic acid, 0.90% by mass of glutamic acid, 0.66% by mass of β-alanine, 1.94% by mass of 1-amino-2-propanol, benzene An etching liquid raw material comprising 0.11% by mass of urea and 0.87% by mass of ethylenediaminetetraacetic acid and 92.84% by mass of water were mixed to prepare an etching concentrate.

[0110] 35% hydrogen peroxide and the etching concentrate were mixed to prepare an etching solution having a hydrogen peroxide concentration of 5.30% by mass. Furthermore, copper sulfate was added, and it prepared so that the copper ion concentration might be 2000 ppm. In addition, it was used at a liquid temperature of 30°C. Table 1 shows the concentration of each component in the whole etching solution and the results of each evaluation item.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com