Astaxanthin and hippophae rhamnoides fruit powder tabletting sweets and preparation method thereof

A technology for tableting candy and astaxanthin, which is applied in confectionery, confectionary industry, food forming, etc., can solve the problems of reduced antioxidant capacity, easy inactivation, and unfavorable preservation of vitamin C activity, and achieves strong antioxidation , strong antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

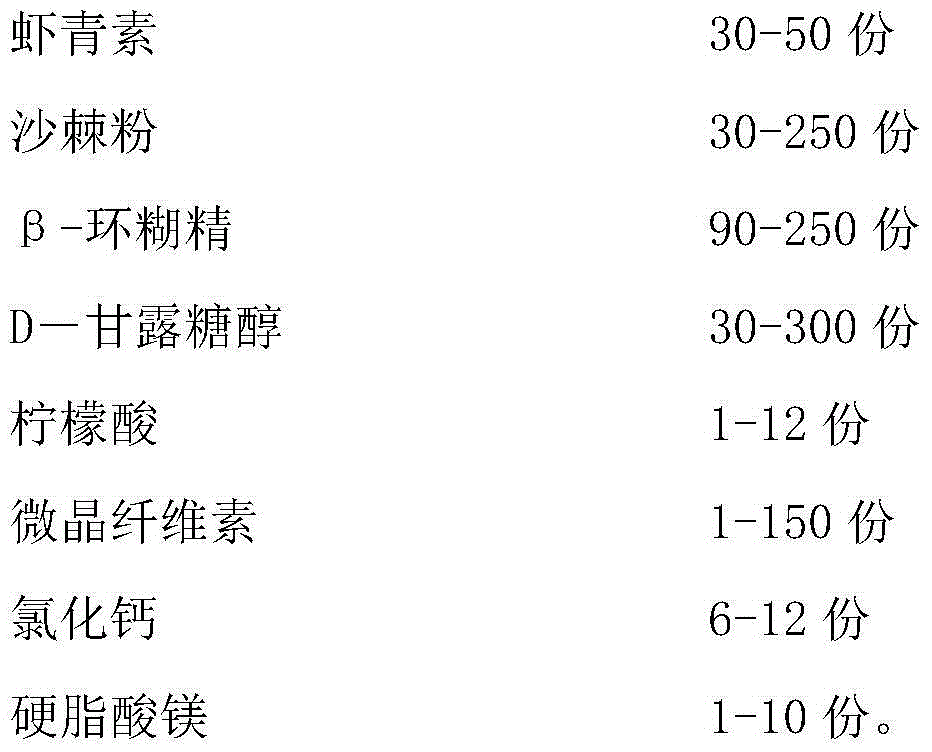

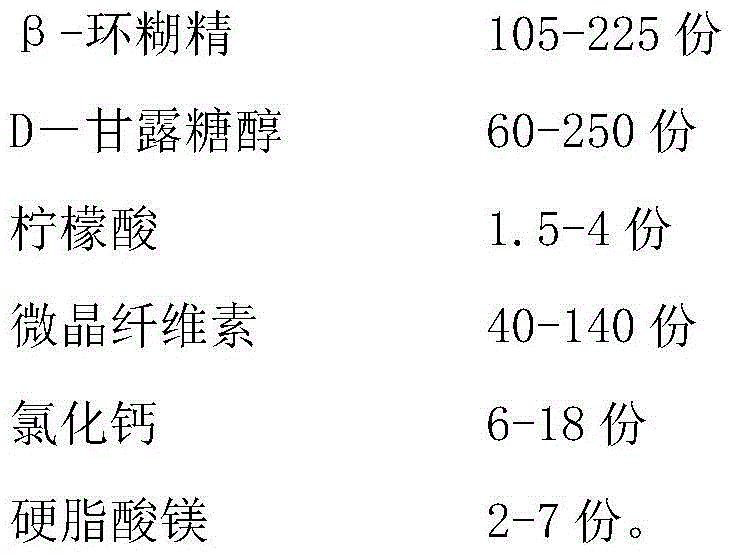

Method used

Image

Examples

experiment example 1

[0041] Experimental investigation of antioxidation of astaxanthin and seabuckthorn powder mixed powder in different proportions of experimental example 1

[0042] 1. Samples, animals, reagents and equipment

[0043] Astaxanthin (Xi’an Haoyuan Biotechnology Co., Ltd., HY20140513), seabuckthorn powder (Xi’an Ruilin Biotechnology Co., Ltd., 20130321), aged KM mice over 8 months old and weighing 18g to 22g (Qinghai Provincial Experimental Animal Center) , certificate number 20130001).

[0044] 2. Experimental method

[0045] 70 aged KM mice were grouped according to the level of MDA in blood, and randomly divided into 7 experimental groups, 10 mice in each group. 6 experimental groups and 1 solvent control group, the test samples of the 7 experimental groups were purified water (Experiment No. 1), 3g fine powder of astaxanthin (Experiment No. 2), 1.5g fine powder of astaxanthin + 1.5 g sea buckthorn powder fine powder (No. 3 experiment), 0.75g astaxanthin fine powder+2.25g sea ...

experiment example 2

[0065] The investigation experiment of experimental example 2 drying conditions

[0066] 1. Raw materials, reagents and equipment

[0067] Astaxanthin (Xi'an Haoyuan Biotechnology Co., Ltd., HY20140513), β-cyclodextrin (Qufu Tianli Pharmaceutical Excipients Co., Ltd., 131118), D-mannitol (Qingdao Mingyue Seaweed Group Co., Ltd., 20130531), Citric acid (Linyi Lanshan District Lvsen Chemical Co., Ltd., 20140120), calcium chloride (Guangzhou Suixin Chemical Co., Ltd., 20140315), microcrystalline cellulose (Qufu Tianli Pharmaceutical Excipients Co., Ltd., 140620A), seabuckthorn powder (Xi'an Ruilin Biotechnology Co., Ltd., 20130321), purified water; ball mill (Zhengzhou Jiufu Machinery Equipment Co., Ltd., ), sampling sieve (Beijing Xiangyu Weiye Instrument Equipment Co., Ltd. home, HY-200), electric blast drying oven (Type 101 electric blast drying oven, Beijing Yongguangming Medical Instrument Factory Type 101).

[0068] 2. Experimental method

[0069] Parallel six experimen...

experiment example 3

[0093] Experimental example 3 Astaxanthin embedding agent selection experiment

[0094] 1. Raw materials, reagents and equipment

[0095] Astaxanthin (Xi'an Haoyuan Biotechnology Co., Ltd., HY20140513), β-cyclodextrin (manufacturer Qufu Tianli Pharmaceutical Excipients Co., Ltd., batch number 131118), modified starch (Xiwang Pharmaceutical Co., Ltd., 20130530), gum arabic (Henan Yuxing Biotechnology Co., Ltd., 20130420), maltodextrin (Xiwang Pharmaceutical Co., Ltd., 20130730), D-mannitol (Qingdao Mingyue Seaweed Group Co., Ltd., 20130531), citric acid (Lvsen Chemical Industry, Lanshan District, Linyi City) Co., Ltd., 20140120), calcium chloride (Guangzhou Suixin Chemical Co., Ltd., 20140315), microcrystalline cellulose (Qufu Tianli Pharmaceutical Excipients Co., Ltd., 140620A), seabuckthorn powder (Xi’an Ruilin Biotechnology Co., Ltd., 20130321 ), purified water; ball mill (manufacturer and model of Zhengzhou Jiufu Machinery Equipment Co., Ltd. ), sampling sieve (Beijing X...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com