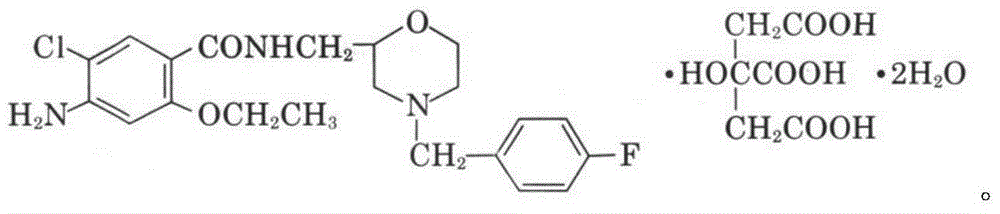

Rapidly-dissolving mosapride citrate composition

A technology of mosapride citrate and its composition, which is applied in the field of mosapride citrate composition, can solve problems such as prone to instability, increased production cost, and unfavorable quality control, so as to avoid instability , easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

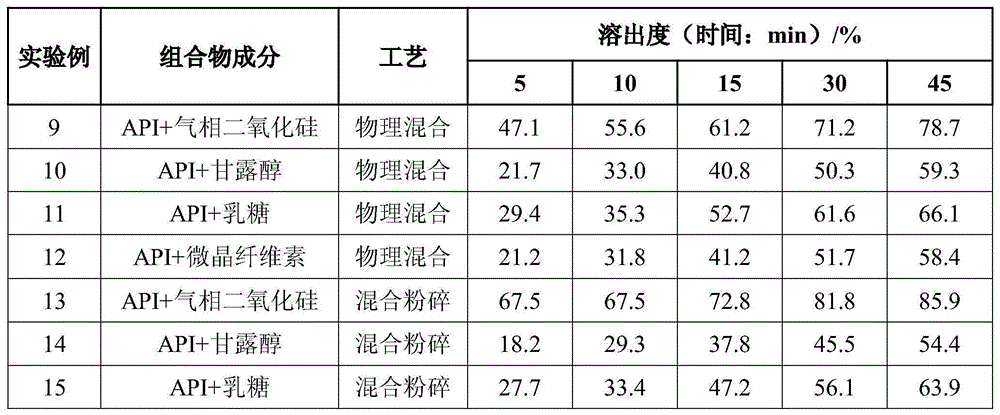

Method used

Image

Examples

Embodiment 1

[0083]

[0084]According to the above prescription, take the API with a particle size D50 of 1.05um and fumed silica and add it to a pulverizer with a rotation speed of 4500 rpm, mix and pulverize it for 25 seconds to make a composition, and mix the prepared composition with mannitol, micro Crystalline cellulose is mixed, then sodium carboxymethyl starch is added, mixed evenly, passed through a 40-mesh sieve to disperse once, magnesium stearate is added for total mixing, mixed evenly, compressed into tablets, and obtained. Test the dissolution rate of the preparation according to the methods described in "1.1" and "1.2", and the results are as follows:

[0085] Table 7 embodiment 1 preparation dissolution investigation result

[0086]

Embodiment 2

[0088]

[0089] According to the above prescription, take the API with a particle size D50 of 1.7um and fumed silica and add it to a pulverizer with a rotating speed of 2000 rpm, mix and pulverize it for 40 seconds to make a composition, and mix the prepared composition with carboxymethyl starch Mix sodium and crospovidone, then add microcrystalline cellulose and sucrose, mix evenly, pass through a 40-mesh sieve to disperse once, add magnesium lauryl sulfate for total mixing, mix evenly, and press into tablets to obtain. Test the dissolution rate of the preparation according to the methods described in "1.1" and "1.2", and the results are as follows:

[0090] Table 8 embodiment 2 preparation dissolution investigation result

[0091]

Embodiment 3

[0093]

[0094] According to the above prescription, API with a particle size D50 of 1.7um and fumed silica were added to a pulverizer with a rotating speed of 1500 rpm, mixed and pulverized for 30 seconds to make a composition, and the prepared composition was mixed with aspartame Mix, then add low-substituted hydroxypropyl cellulose, microcrystalline cellulose, talcum powder, mix evenly, disperse once through a 40-mesh sieve, mix evenly, and press into tablets to obtain. Test the dissolution rate of the preparation according to the methods described in "1.1" and "1.2", and the results are as follows:

[0095] Table 9 Example 3 Preparation Dissolution Investigation Result

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com