Process for controlling or reducing plasticizers in fats and oils obtained therefrom

A technology of plasticizer and grease, which is applied in the field of grease processing, can solve the problems of low removal rate, small processing capacity, limited production capacity, etc., and achieve the effects of simple process operation, simplified process flow and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-35

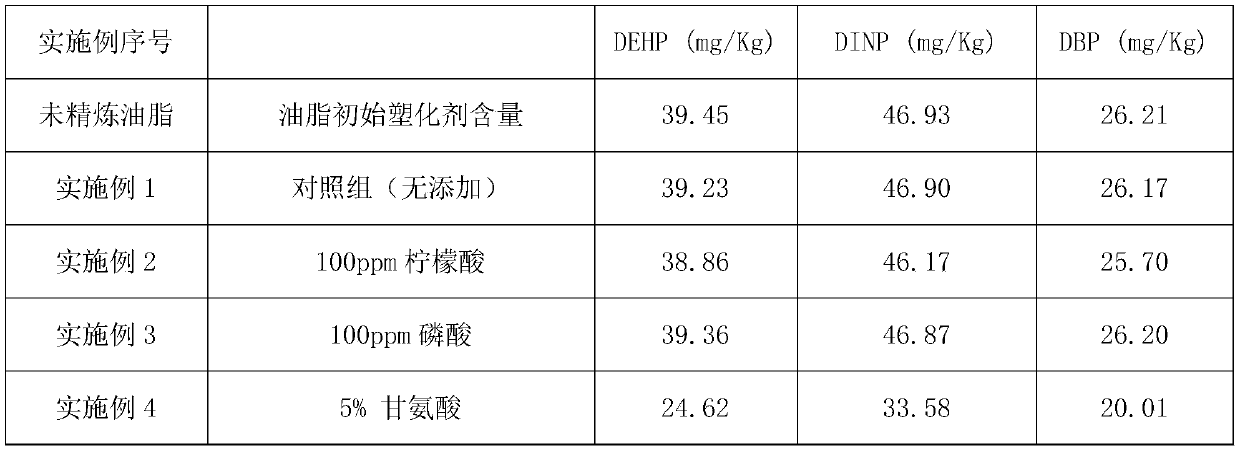

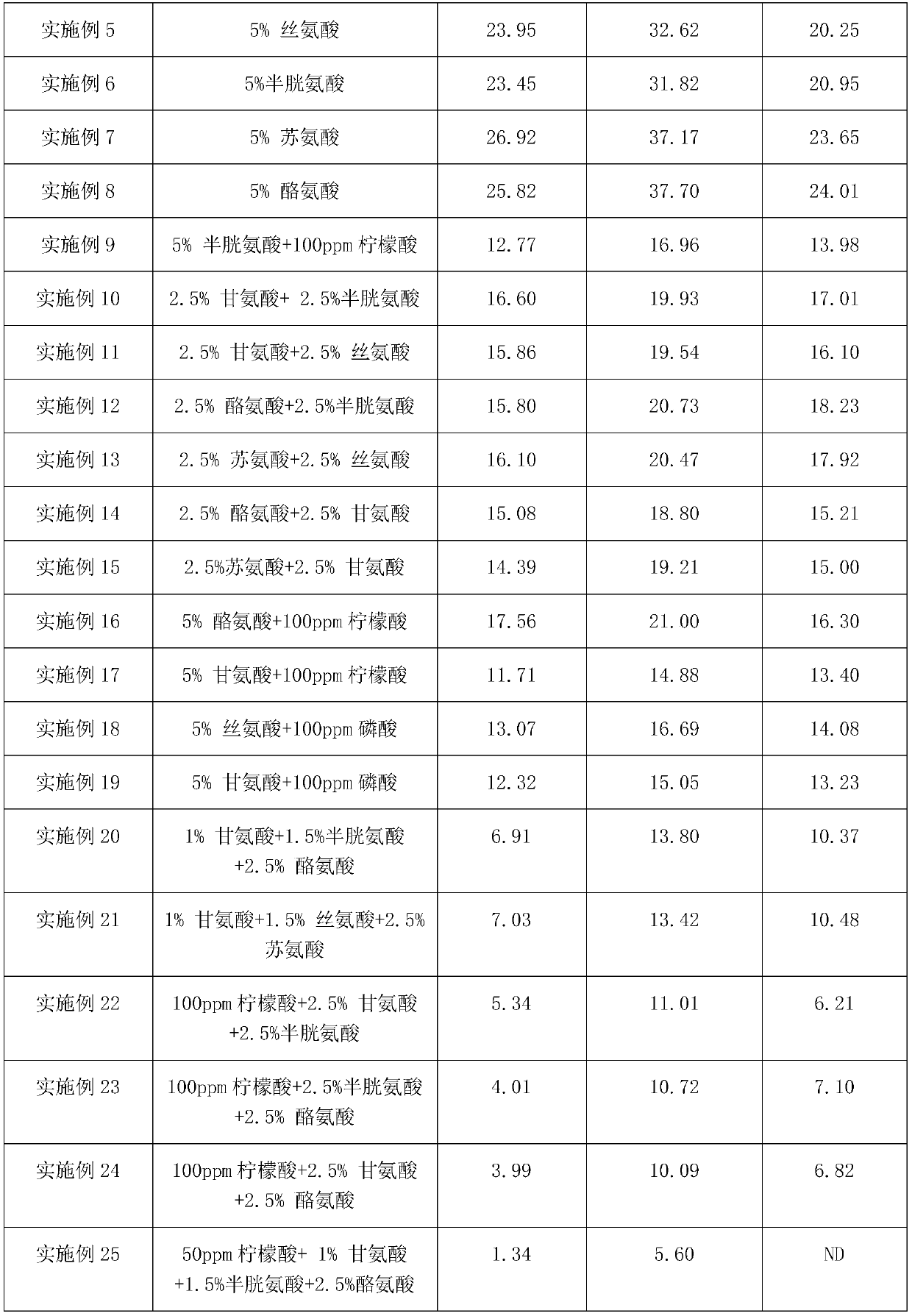

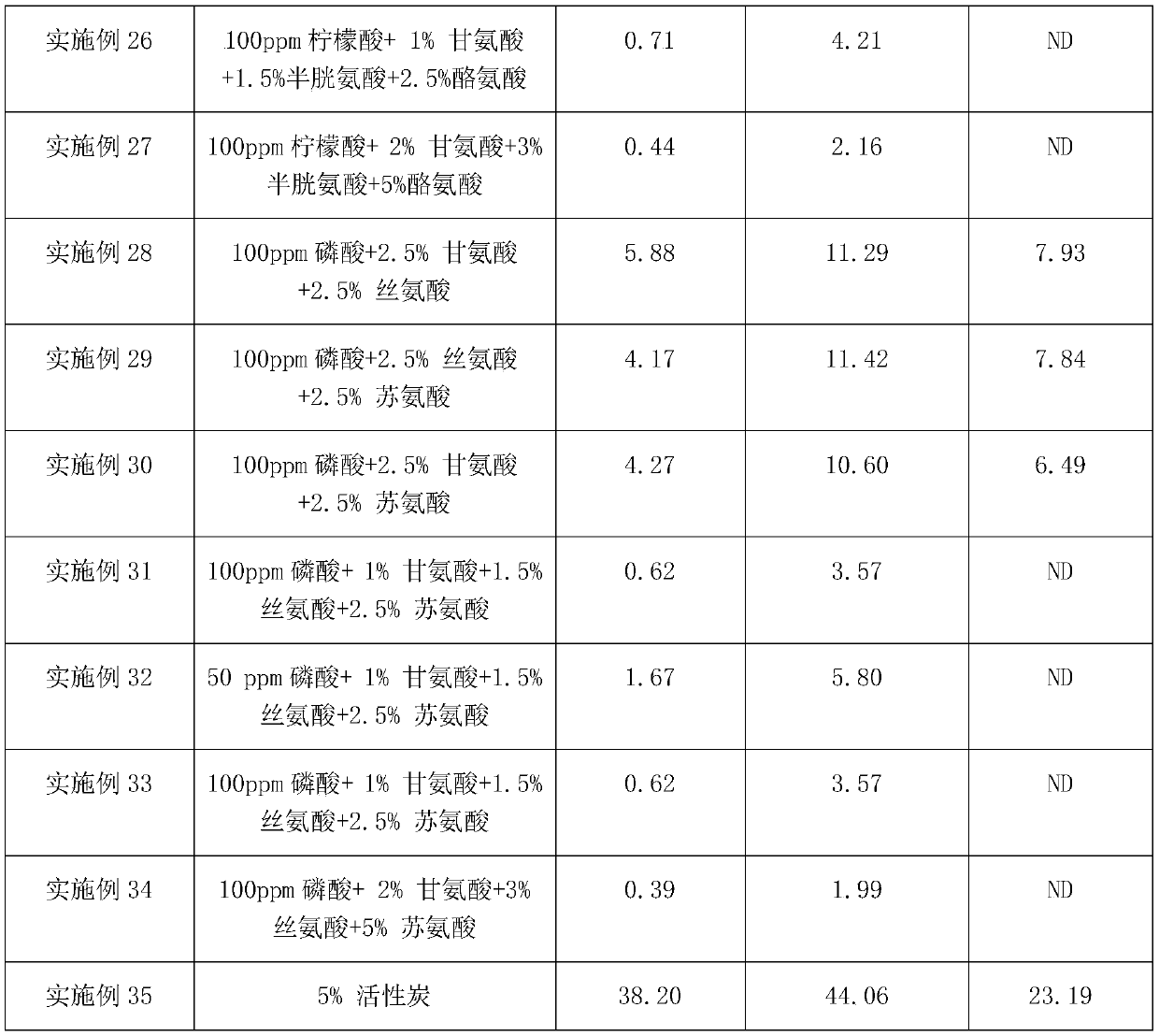

[0038] Take 200 grams of the above-mentioned phthalate plasticizers exceeding the standard, and list the initial content of phthalate plasticizers contained in the grease measured according to GBT21911-2008 in Table 1 below.

[0039] Then, based on the weight of the oil, add the amino acid adsorbent and / or nitrogen-free acid substances shown in Table 1 below, heat to 110°C and stir for 35 minutes to obtain refined oil, according to GBT21911-2008 The amount of phthalate plasticizers in the grease was measured and listed in the table below.

[0040] The amino acid adsorbents and / or nitrogen-free acid substances used in the examples are all substances known in the art and can be purchased from the market.

[0041] The following table 1 shows the initial content of the phthalate plasticizer contained in the oil, the type and quantity of the amino acid adsorbent and / or the acid substance without nitrogen element added in each embodiment, and Content of phthalate plasticizers in re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com