Lignocellulose pre-processing method

A lignocellulose and pretreatment technology, applied in the field of bioengineering, can solve the problems of unsatisfactory hemicellulose recycling rate, cellulose enzymatic conversion rate, steam, raw material consumption, low degree of material treatment, etc., and achieve good treatment effect , reduce the loss of raw materials, and improve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

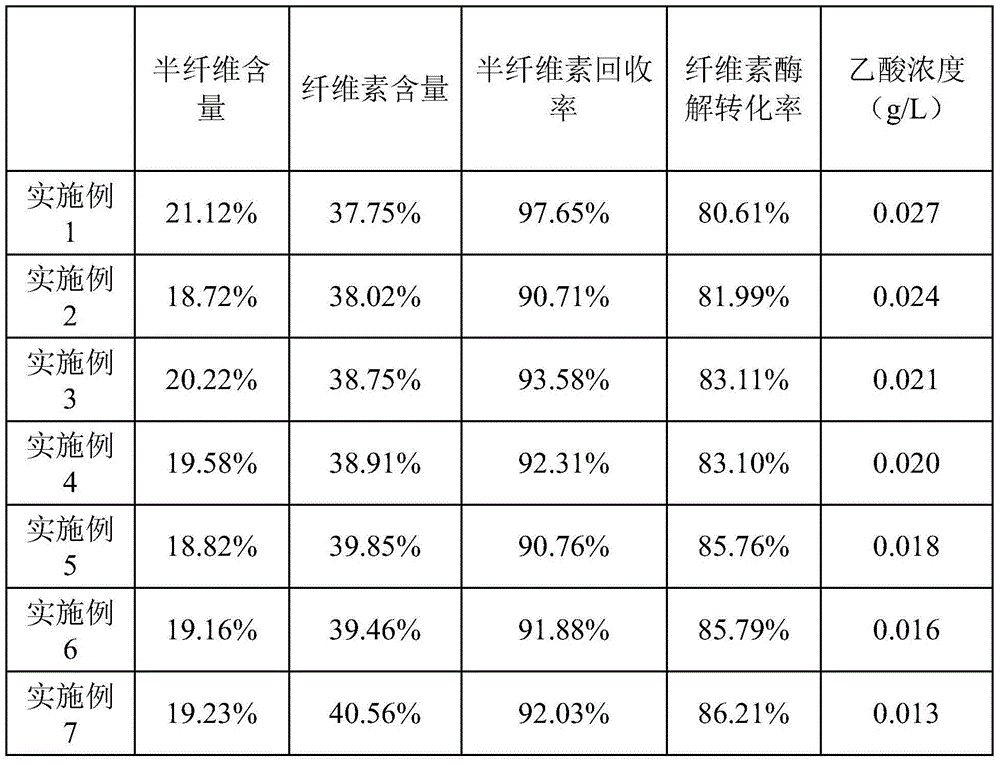

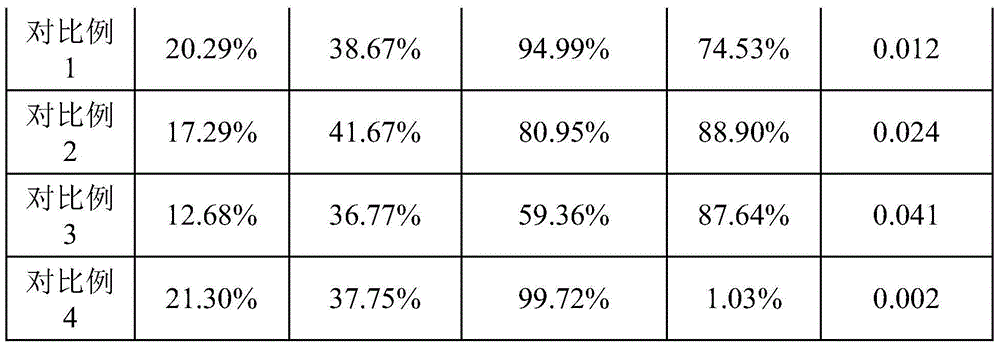

Examples

Embodiment 1

[0026] The pretreatment method of the lignocellulose of the present embodiment, concrete steps are as follows:

[0027] 1) Infiltration: take lignocellulose-containing raw materials and presoak liquid according to the weight ratio of 1:1.5, mix, and infiltrate;

[0028] 2) Dehydration: dehydrating the infiltrated raw material obtained in step 1) until the dry matter content is greater than or equal to 30%;

[0029] 3) Steam explosion: put the dehydrated raw material obtained in step 2) in a steam explosion device, feed saturated steam with a pressure of 1.08 MPaG, and mix at 210° C. for 5 minutes to obtain the product.

[0030] In this embodiment, the lignocellulose-containing raw material is oat husk; the presoaking solution is water.

Embodiment 2

[0032] The pretreatment method of the lignocellulose of the present embodiment, concrete steps are as follows:

[0033] 1) Soaking: Mix the lignocellulose-containing raw material with the prepreg in a weight ratio of 1:20, and soak for 100 minutes;

[0034] 2) Dehydration: dehydrating the infiltrated raw material obtained in step 1) until the dry matter content is greater than or equal to 35%;

[0035] 3) Steam explosion: put the dehydrated raw materials obtained in step 2) in a steam explosion device, feed supersaturated steam with a pressure of 0.35 MPaG, and mix at 148° C. for 48 minutes to obtain the product.

[0036] In this embodiment, the lignocellulose-containing raw material is a mixture of corncobs and hardwood; the presoaking solution is a sodium hydroxide solution with a concentration of 2 mol / L.

Embodiment 3

[0038] The pretreatment method of the lignocellulose of the present embodiment, concrete steps are as follows:

[0039] 1) Soaking: Mix the lignocellulose-containing raw material with the prepreg in a weight ratio of 1:11, and soak for 5 minutes;

[0040] 2) Dehydration: dehydrating the infiltrated raw material obtained in step 1) until the dry matter content is greater than or equal to 40%;

[0041] 3) Extrusion: put the dehydrated raw material obtained in step 2) into an extrusion extruder, feed saturated steam with a pressure of 1.8 MPaG, and mix at 180° C. for 90 minutes to obtain the product.

[0042] In this embodiment, the lignocellulose-containing raw material is a mixture of cork, nut shell, and grass; the presoaking solution is a sulfuric acid solution with a concentration of 0.2 mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com