Paclitaxel slow-release temperature-sensitive gel and preparation method thereof

A temperature-sensitive gel and temperature-sensitive gel matrix technology, which can be used in pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., can solve the problems of fast drug release rate, low solubility, insufficient strength, etc. Reduce systemic side effects, improve therapeutic efficacy, and facilitate administration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of paclitaxel-Soluplus, paclitaxel-poloxamer 407 thermosensitive gel

[0044] Isotonic phosphate buffer solution is prepared as follows: Weigh NaCl8g, KH 2 PO 4 0.2g, Na 2 HPO 4 12H 2 Add O2.9g and KCl0.2g into the container, then add 1000mL of degassed water for injection to dissolve, and adjust the pH to 7.4 with NaOH.

[0045] Add Soluplus to isotonic phosphate buffer, swell at 4°C to obtain a uniform dispersion system, and pass through 0.45 μm and 0.22 μm microporous membranes to sterilize the obtained dispersion at 0-30°C, as a temperature-sensitive gel matrix system; dissolving paclitaxel in ethanol to prepare a paclitaxel solution; then adding the paclitaxel solution to the Soluplus thermosensitive gel matrix system under stirring at room temperature to obtain a paclitaxel-Soluplus or paclitaxel-poloxamer 407 thermosensitive gel (0-30°C Store for future use, in a uniformly dispersed dispersion system).

[0046] Add Poloxamer 407 into i...

Embodiment 2

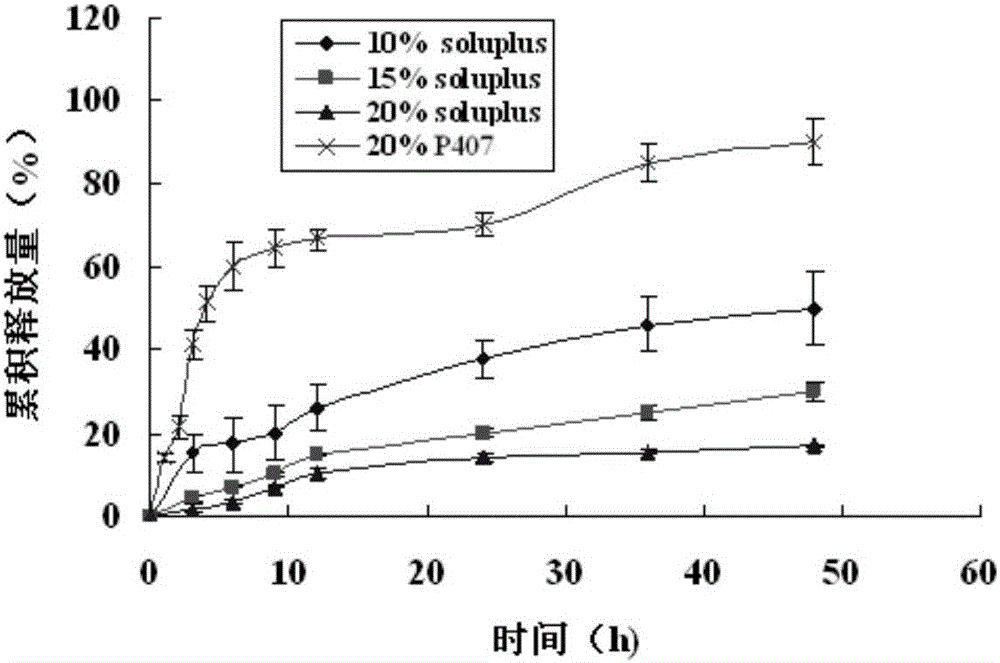

[0050] Example 2 Determination of In Vitro Release of Paclitaxel-Soluplus and Paclitaxel-Poloxamer 407 Thermosensitive Gel

[0051] Take the temperature-sensitive gel preparation prepared in Example 1, and adopt the filmless release rate measurement method. Accurately weigh 0.2mL paclitaxel thermosensitive gel respectively, put them in test tubes, let stand at 37°C for 5min, and wait for them to gel completely; Shake (37°C, 100rpm), sample 1mL at different time points, and add 1mL of fresh medium at the same temperature. The sample was centrifuged at 10,000 rpm for 5 min, and the supernatant was taken, and the concentration of paclitaxel was determined by HPLC. Comparison of in vitro release of paclitaxel-Soluplus and paclitaxel-poloxamer 407 thermosensitive gel figure 1 .

[0052] Conclusion: When 20% poloxamer 407 was used as the thermosensitive gel matrix, the cumulative release of paclitaxel reached 60% in 6 hours in vitro, and nearly 90% in 48 hours. When Soluplus is ...

Embodiment 3

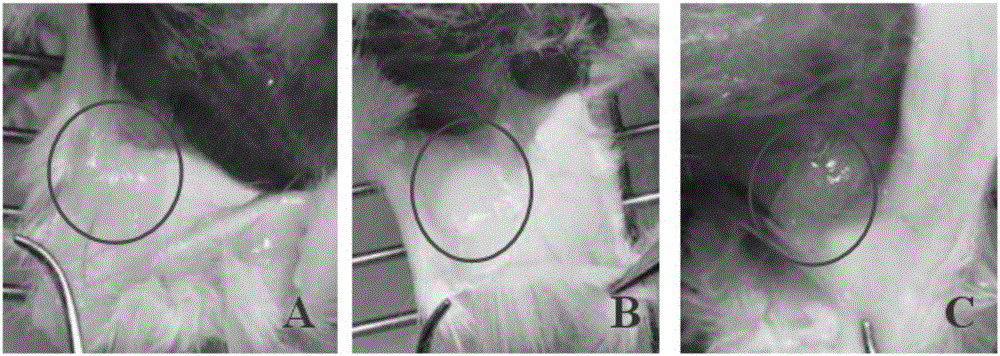

[0053] Example 3 Comparison of In Vivo Formability, Retention and Release of Paclitaxel-Soluplus and Paclitaxel-Poloxamer 407 Thermosensitive Gels

[0054] In Example 1, paclitaxel-Soluplus (10%, 20%) or paclitaxel-poloxamer 407 (20%) thermosensitive gel was injected into 0.2 mL of mice (ICR, male, body weight 30 ± 5g, Zhejiang Academy of Medical Sciences) subcutaneously on the back, 3 mice in each group, the mice were sacrificed regularly, the subcutaneous section was cut open and the gelation situation of the preparation in vivo was observed, and the drug content in the residual gel was determined by HPLC. Comparison of In Vivo Formability of Paclitaxel-Soluplus and Paclitaxel-Poloxamer 407 Thermosensitive Gels figure 2 .

[0055] Conclusion: 6 hours after subcutaneous injection of 20% F127 drug-loaded gel, there is only a very small amount of gel residue in the injection site. The residual drug concentration measured by HPLC method is only 25.7±2.3% of the injected amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com