Novel electromagnetic wave radiation protection material decomposition generator

A radiation protection, electromagnetic wave technology, applied in metal material coating process, sputtering coating, ion implantation coating and other directions, can solve the problems of inability to mass production, weak absorption, thick coating, etc., to prevent current disorder. Channeling, speed up the reaction, good effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

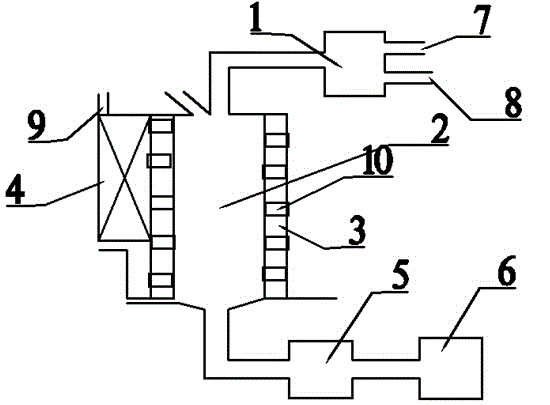

[0019] A new type of electromagnetic wave radiation protection material decomposition generator, comprising a constant temperature evaporation chamber 1, a decomposition chamber 2, an electric heating chamber 3, an electrified spiral coil 4, a collection box 5, and an exhaust gas treatment chamber 6, characterized in that: the constant temperature evaporation chamber 1 The left end is provided with an opening as a nitrogen channel, and the right end is provided with two parallel channels up and down, the lower one of the two channels is a nitrogen channel, and a pentahydroxyferric acid liquid guide channel is provided on it, and the nitrogen gas is decomposed The opening at the upper end of the chamber 2 enters the interior of the decomposition chamber 2, and then decomposes after being mixed with the pentahydroxy iron liquid. The left and right edges of the decomposition chamber 2 are provided with electric heating chambers, and the left and right ends of the electric heating c...

Embodiment 2

[0021] Example 2 as figure 1 Shown, it is improved on the basis of embodiment 1, is provided with a plurality of electric heating plates 10 in its electric heating chamber 3, and electric heating plate 10 is made of two layers of bakelite boards, and thickness is 10cm. Using a wooden electric heating plate, the heat resistance effect is very good, and at the same time, the design is suitable for thickness without being too bulky and will not affect the quality. The material selection of the electric heating plate must have good flame retardancy, otherwise it will be damaged during the heating process. Very prone to high temperature combustion phenomenon.

Embodiment 3

[0023] Example 3 as figure 1 As shown, it is improved on the basis of Example 1, adopts gas heating decomposition method in its described decomposition chamber 2, and produces carboxyl iron fiber by protecting nitrogen. The use of protective gas to decompose can effectively speed up the reaction speed, and at the same time ensure the safety of the decomposition process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com