Preparation method of aluminum nitride coating adjustable in relative permittivity

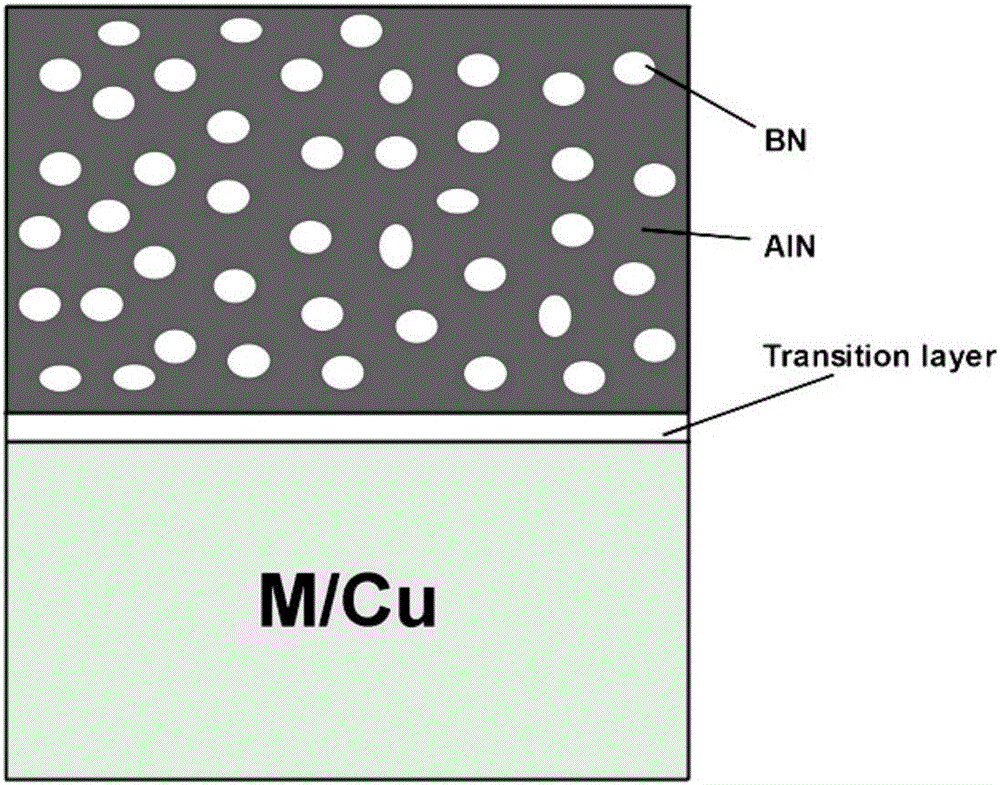

A technology of dielectric coefficient and aluminum nitride, which is applied in the field of preparing AlN coating with adjustable relative permittivity on the surface of copper-carbon alloy substrate, can solve the problems of limited applicability and achieve low dielectric loss and high thermal conductivity film -Effect of base binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

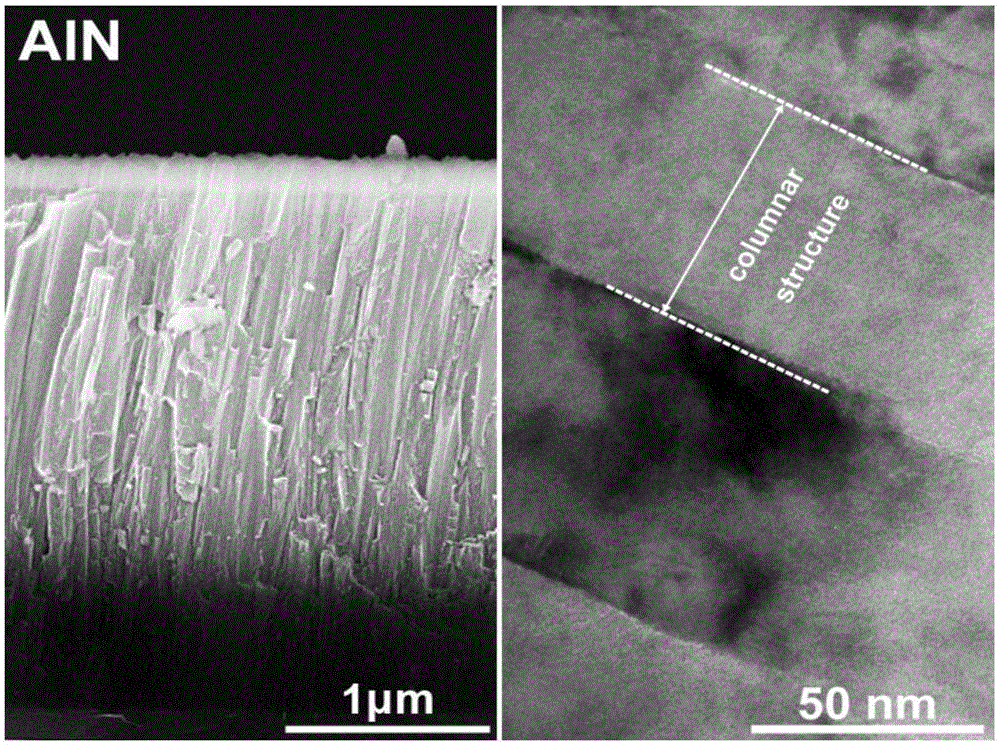

Embodiment 1

[0055] 1. Substrate pretreatment: (1) Solvent cleaning treatment. First use isopropanol to ultrasonically clean for 10 minutes, then use 98% alcohol solution to ultrasonically clean for 10 minutes, and then use ultrapure water to ultrasonically clean for 3 minutes after taking it out. (2) Ion source bombardment cleaning treatment. The substrate was cleaned by Hall ion source for 5 min, and the ambient pressure was 2.2×10 -2 Pa, Ar flow rate is 11.5sccm, substrate bias voltage is -180V, cathode current is 22.5A, cathode voltage is 32.5V, anode current is 6.2A, anode voltage is 65V.

[0056] 2. Deposit the metal Cr transition layer on the surface of the copper-carbon alloy substrate by pulse DC sputtering

[0057] (1) Pretreatment of metal Cr, Al and ceramic BN targets. The working temperature of the deposition chamber is heated to 250° C., the substrate is heated to 350° C., and the gas in the deposition chamber is extracted. Heat and bake the cavity for a long time to remo...

Embodiment 2

[0062] 1. Substrate pretreatment: (1) Solvent cleaning treatment. With embodiment 1. (2) Ion source bombardment cleaning treatment. With embodiment 1.

[0063]2. Depositing a metallic Cr transition layer by magnetron sputtering on the surface of the copper-carbon alloy substrate: (1) Target pre-sputtering. With embodiment 1. (2) Depositing a metal transition layer. With embodiment 1.

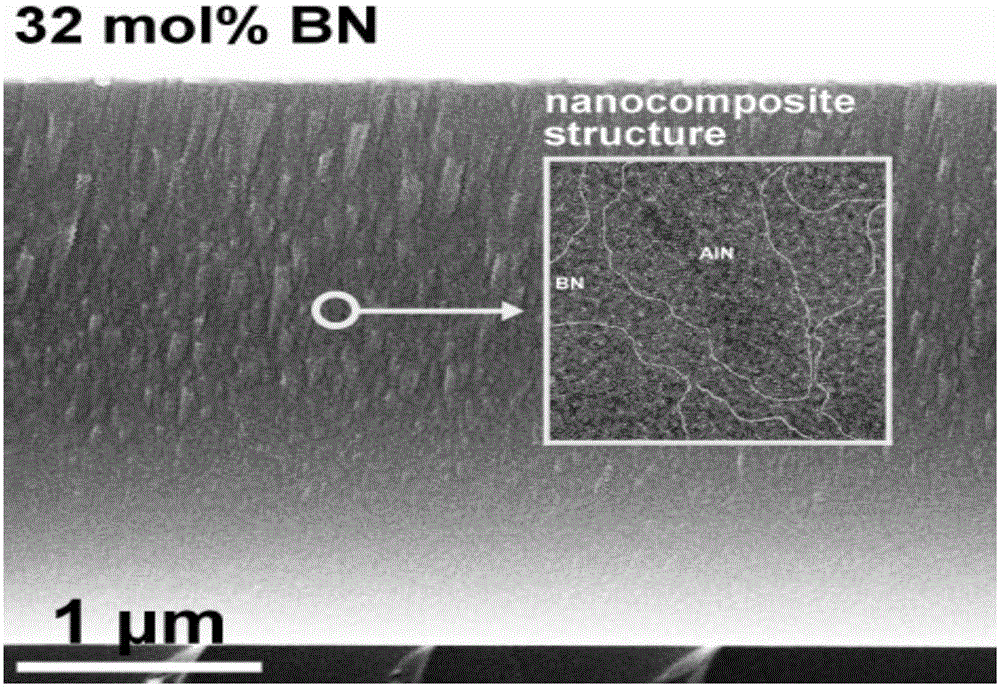

[0064] 3. Deposition of AlN-BN nanocomposite structure coating: After the metal Cr transition layer is deposited, maintain the chamber temperature at 200°C and the substrate at 250°C, and rotate the sample stage so that the copper-carbon alloy substrate is placed between the metal Al target and the BN The middle position of the target, and the distance from the two targets is 200mm. At this time, N 2 gas, adjust the flow rate so that Ar gas and N 2 The total gas flow is 50sccm, N 2 The partial pressure ratio is 30%. Adjust the pressure of the deposition chamber to 0.35Pa, use an interme...

Embodiment 3

[0068] 1. Substrate pretreatment: 1) Solvent cleaning treatment. Same as Example 1. 2) Ion source bombardment cleaning treatment. With embodiment 1.

[0069] 2. Depositing a metallic Cr transition layer by magnetron sputtering on the surface of the copper-carbon alloy substrate: (1) Target pre-sputtering. With embodiment 1. (2) Depositing a metal transition layer. With embodiment 1.

[0070] 3. Deposition of AlN-BN nanocomposite structure coating: After the metal Cr transition layer is deposited, maintain the chamber temperature at 200°C and the substrate at 250°C, and rotate the sample stage so that the copper-carbon alloy substrate is placed between the metal Al target and the BN The middle position of the target, and the distance from the two targets is 200mm. At this time, N 2 gas, adjust the flow rate so that Ar gas and N 2 The total gas flow is 50sccm, N 2 The partial pressure ratio is 30%. Adjust the pressure of the deposition chamber to 0.35Pa, use an intermedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com