Enhanced Fin Insulated Gate High Electron Mobility Transistor

A high electron mobility, insulated gate technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of serious short channel effect, disadvantageous nano-scale digital integrated circuits, large sub-threshold swing, etc. Channel effect, low gate leakage current, and the effect of enhancing gate control capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

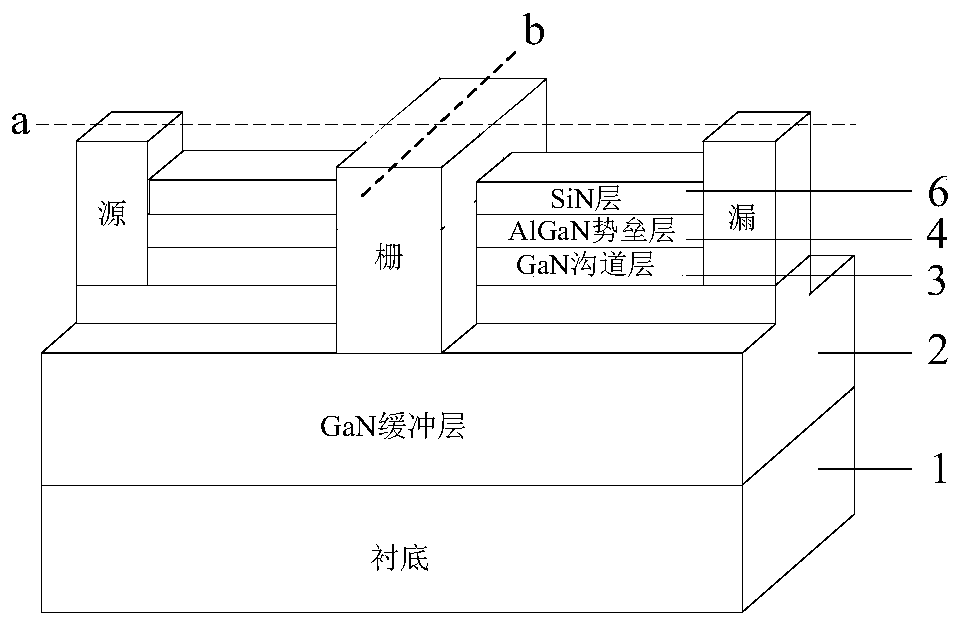

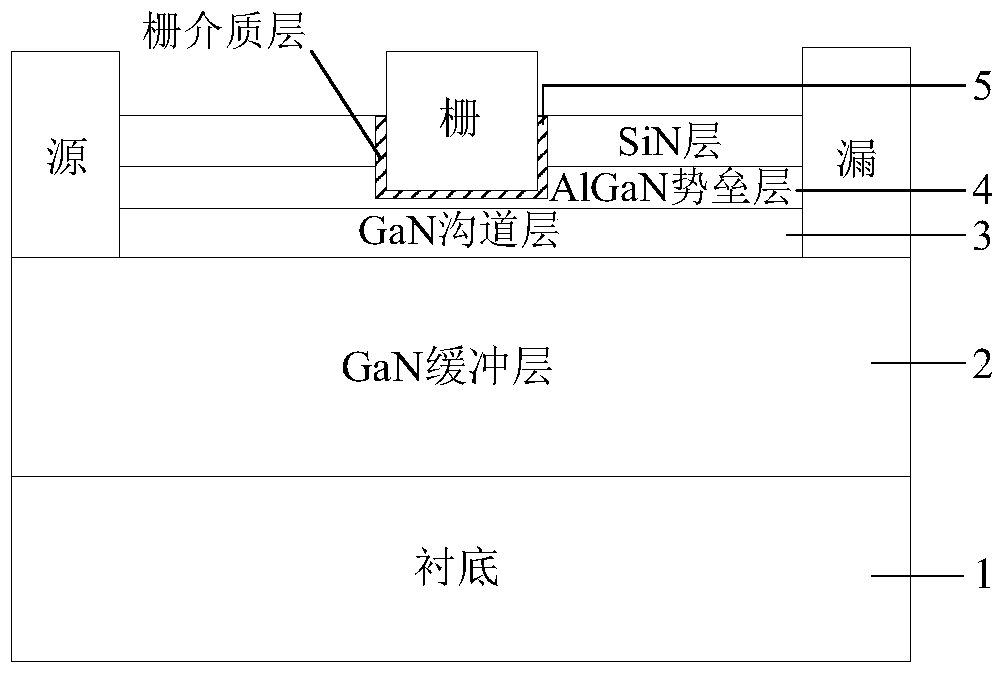

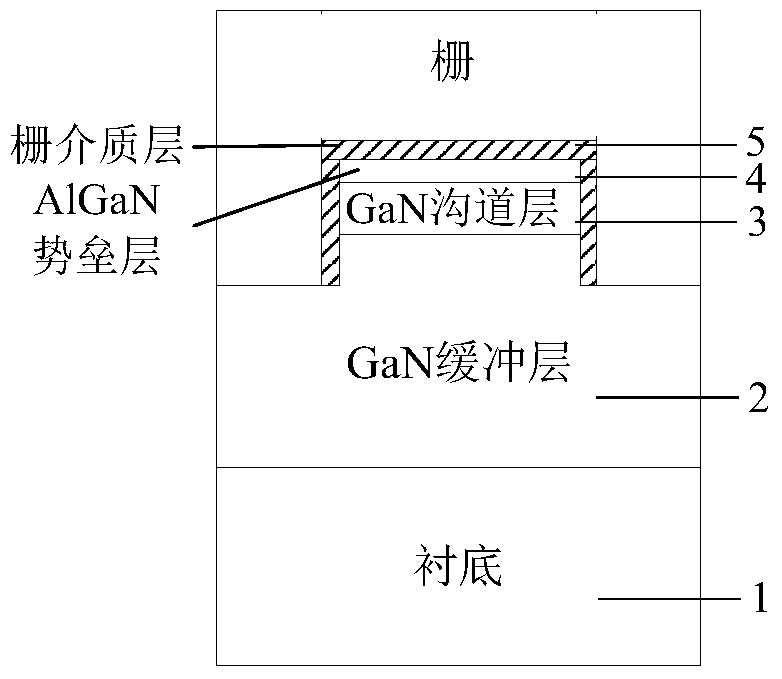

[0041] Example 1: Fabrication of a fin-type AlGaN / GaN heterojunction with a width of 200nm and a groove gate depth of 8nm enhanced fin-type insulated gate high electron mobility crystal.

[0042] Step 1: growing a buffer layer.

[0043] At a temperature of 700°C and a pressure of 1.5×10 4 Under the process conditions of Pa, the use of metal organic compound chemical vapor deposition MOCVD equipment in Figure 4 A GaN buffer layer with a thickness of 1 μm is grown on the SiC substrate shown in (a), and the reaction gases are trimethylgallium and ammonia.

[0044] Step 2: growing a channel layer.

[0045] At a temperature of 850°C and a pressure of 1.5×10 4 Under the process conditions of Pa, a 5nm-thick GaN channel layer is grown on the GaN buffer layer by using metal organic compound chemical vapor deposition MOCVD equipment, and the reaction gases are trimethylgallium and ammonia.

[0046] Step 3: growing a barrier layer.

[0047] At a temperature of 950°C and a pressure...

Embodiment 2

[0065] Example 2: Fabrication of a fin-type AlGaN / GaN heterojunction with a width of 300nm and a groove gate depth of 5nm enhanced fin-type insulated gate high electron mobility crystal.

[0066] Step A: growing a buffer layer on the substrate.

[0067] A layer of GaN buffer layer with a thickness of 1.5 μm was grown on the SiC substrate by metal organic compound chemical vapor deposition MOCVD equipment. The growth process conditions were: temperature 700 ° C, pressure 1.5 × 10 4 Pa, the reaction gas is trimethylgallium and ammonia.

[0068] Step B: growing a channel layer on the buffer layer.

[0069] The implementation of this step is the same as step 2 of Embodiment 1.

[0070] Step C: growing a barrier layer on the channel layer.

[0071] Using metal organic compound chemical vapor deposition MOCVD equipment to grow an AlGaN barrier layer with a thickness of 15nm and an Al composition of 30% on the GaN channel layer, the GaN channel layer and the AlGaN barrier layer fo...

Embodiment 3

[0086] Example 3: Fabrication of a fin-type AlGaN / GaN heterojunction with a width of 250nm and a groove gate depth of 7nm enhanced fin-type insulated gate high electron mobility crystal.

[0087] Step 1: Growth buffer layer.

[0088] A layer of GaN buffer layer with a thickness of 1.5 μm was grown on the SiC substrate using metal organic compound chemical vapor deposition MOCVD equipment. The growth process conditions were: temperature 700 ° C, pressure 1.5 × 10 4 Pa, the reaction gas is trimethylgallium and ammonia.

[0089] Step 2: growing a channel layer.

[0090] The implementation of this step is the same as step 2 of Embodiment 1.

[0091] Step 3: Growing a barrier layer.

[0092] On the GaN channel layer, use metal organic compound chemical vapor deposition MOCVD equipment to grow an AlGaN barrier layer with a thickness of 17nm and an Al composition of 27%. The GaN channel layer and the AlGaN barrier layer form an AlGaN / GaN heterojunction , A two-dimensional electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com