Ti<3+>/Ti<4+> mixed-valence lithium titanate negative electrode material doped with iron element and preparation of negative electrode material

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor conductivity, poor performance and serious discharge polarization of lithium titanate materials, and achieves low cost and good crystallization. , the effect of increasing the discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

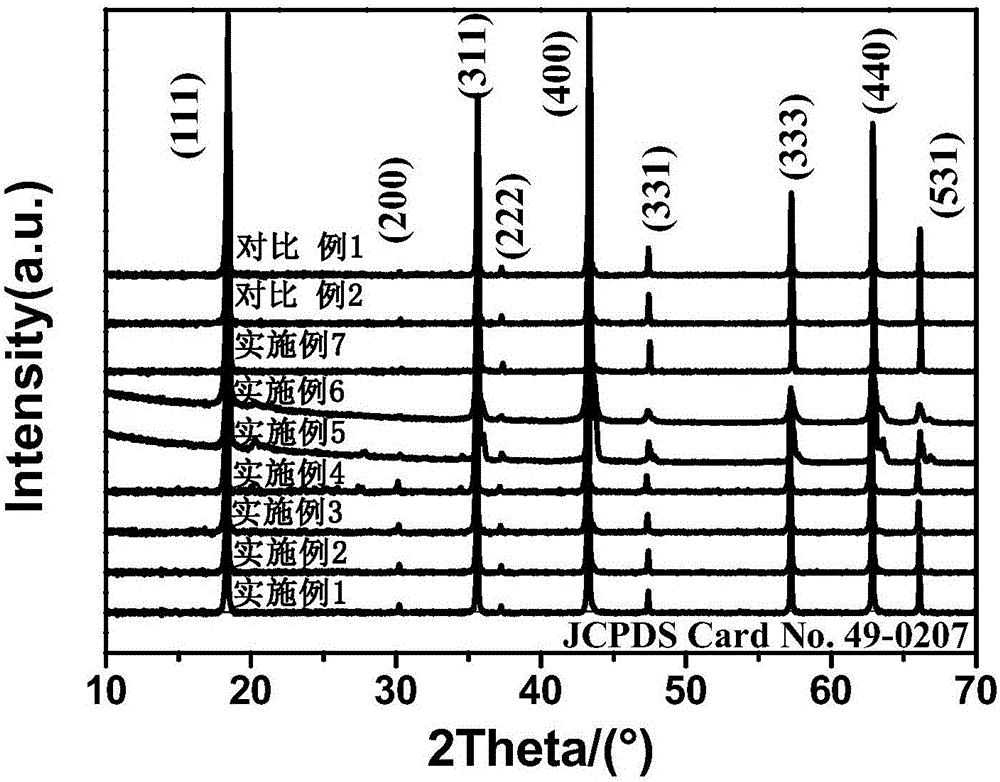

[0025] A kind of Ti 3+ / Ti 4+ A method for preparing a lithium titanate negative electrode material for a lithium ion battery doped with iron elements in a mixed valence state, comprising the following steps:

[0026] (1) Place 2mol of lithium carbonate, 5mol of titanium dioxide and 0.1% of the total mass of reduced iron powder in a planetary ball mill, and grind for 6-10h under the protection of an inert atmosphere;

[0027] (2) Place the mixture obtained in step (1) in a tubular atmosphere furnace, protected by high-purity argon, and sinter at 800°C for 10 hours, and naturally cool to room temperature to obtain Ti 3+ / Ti 4+ mixed valence Li 4 Ti 5-x Fe x o 12-y , where 0<x<0.1, 0.01<y<0.5.

[0028] The synthesized samples were made into pole pieces and assembled into simulated batteries.

[0029] The specific operation is as follows: According to the mass ratio, active material: acetylene black (C): PVDF=80:10:10 ratio weighing, fully grinding and stirring, adding an...

Embodiment 2

[0031] Same as Example 1, the difference is:

[0032] The amount of iron powder accounts for 2% of the total mass.

Embodiment 3

[0034] Same as Example 1, the difference is:

[0035] The amount of iron powder accounts for 3% of the total mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com