Preparation method of negative electrode material of organic system sodium-ion battery

A technology of sodium ion battery and negative electrode material, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor rate performance, low conductivity, and influence on cycle stability, and achieve enhanced conductivity, simple method, The effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a carbon-coated NaTi 2 (PO 4 ) 3 The preparation method of material comprises the following steps:

[0031] In the first step, 0.052molCH 3 COONa·3H 2 O, 0.10molTiO 2 , 0.15mol (NH 4 ) 2 HPO 4 Ball mill with acetone for 2 hours, the speed of the ball mill is 200 rpm, dry at 80°C for 2 hours, grind into powder, and calcinate at 450°C in air for 4 hours;

[0032] In the second step, the powder calcined in the first step is ball-milled with 8.0 g of glucose for 2 hours at a speed of 200 rpm, and then calcined at 800°C for 18 hours under an argon atmosphere to prepare carbon-coated NaTi 2 (PO 4 ) 3 Material.

[0033]TEM measurements show that the carbon coating is continuously coated on the NaTi 2 (PO 4 ) 3 surface, and the thickness of the carbon coating is 3μm-15μm.

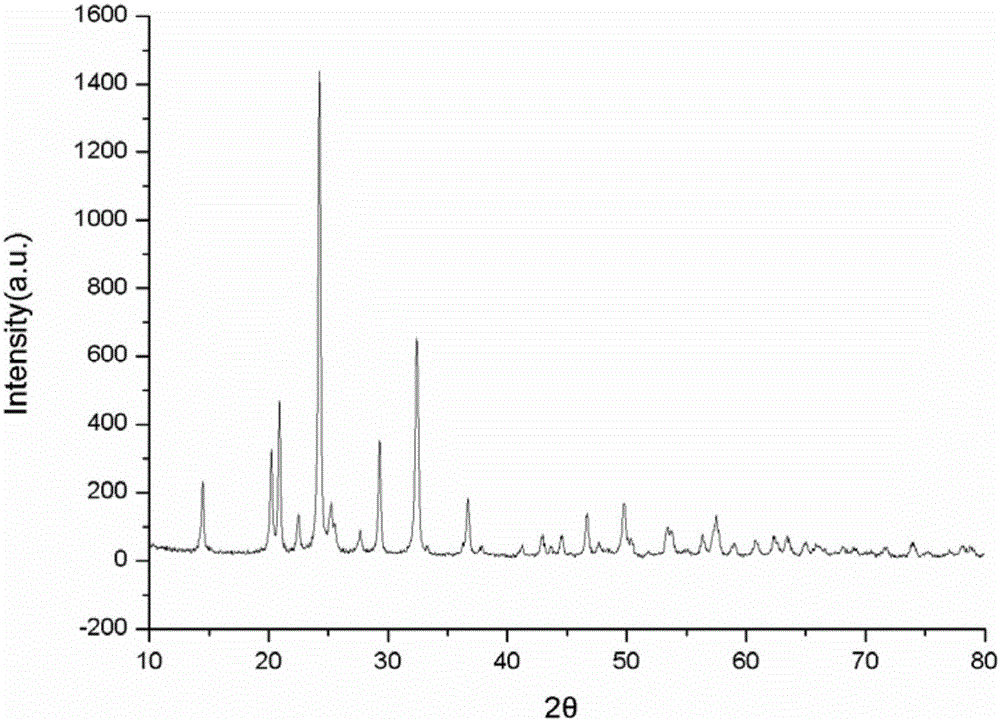

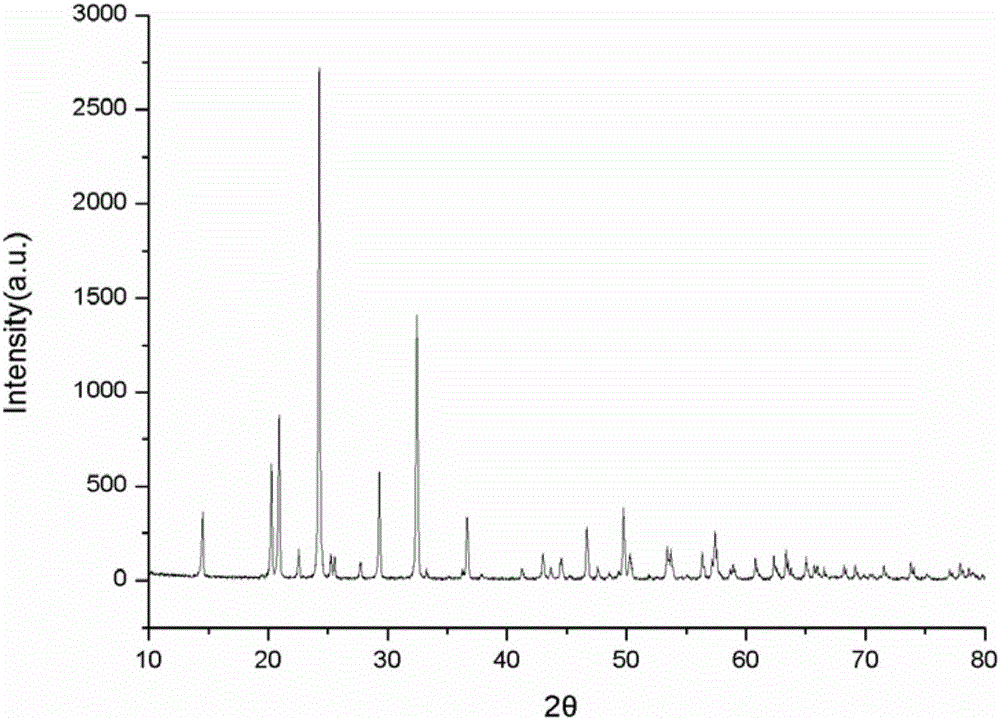

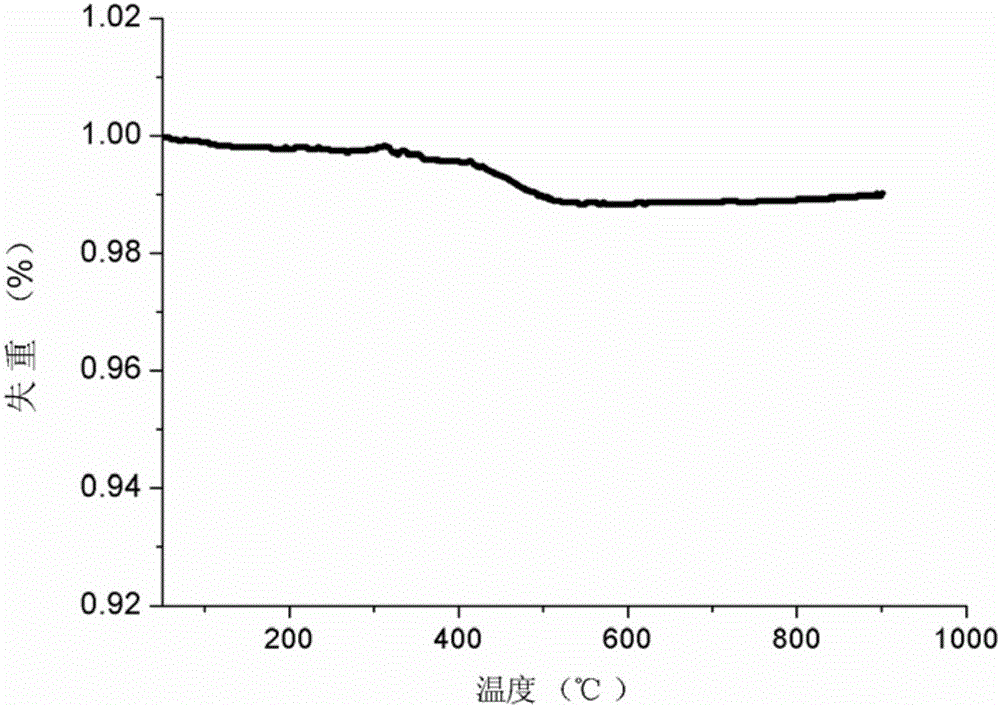

[0034] For the carbon-coated NaTi prepared in Example 1 2 (PO 4 ) 3 The electrochemical properties of the material were tested, specifically, the carbon-coated NaTi...

Embodiment 2

[0037] This embodiment provides a carbon-coated NaTi 2 (PO 4 ) 3 The preparation method of material comprises the following steps:

[0038] In the first step, 0.051molCH 3 COONa·3H 2 O, 0.10molTiO 2 , 0.15mol (NH 4 ) 2 HPO 4 Ball mill with acetone for 3 hours at a speed of 250 rpm, dry at 90° C. for 3 hours, grind into powder, and calcinate at 500° C. in air for 6 hours.

[0039] In the second step, the powder calcined in the first step is ball-milled with 4.0 g of glucose for 3 hours at a speed of 250 rpm, and then calcined at 850°C for 15 hours in a nitrogen atmosphere to prepare carbon-coated NaTi 2 (PO 4 ) 3 Material.

[0040] TEM measurements show that the carbon coating is intermittently coated on the NaTi 2 (PO 4 ) 3 surface, and the thickness of the carbon coating is 2μm-10μm.

[0041] The electrochemical performance and the XRD figure of the material prepared by the method test embodiment 2 adopting the method described in embodiment 1, gained result se...

Embodiment 3

[0044] This embodiment provides a carbon-coated NaTi 2 (PO 4 ) 3 The preparation method of material comprises the following steps:

[0045] In the first step, 0.053molCH 3 COONa·3H 2 O, 0.10molTiO 2 , 0.15mol (NH 4 ) 2 HPO 4 Ball mill with acetone for 2.5 hours, the speed of the ball mill is 300 rpm, dry at 70°C for 5 hours, grind into powder, and calcined in air at 550°C for 2 hours;

[0046] In the second step, the powder calcined in the second step is ball-milled with 2.0 g of glucose for 3 hours at a speed of 300 rpm, and then calcined at 800°C for 20 hours under an argon atmosphere to prepare carbon-coated NaTi 2 (PO 4 ) 3 Material.

[0047] TEM measurements show that the carbon coating is intermittently coated on the NaTi 2 (PO 4 ) 3 surface, and the thickness of the carbon coating is 3μm-8μm.

[0048] The electrochemical performance of the material prepared in Example 3 was tested by the method described in Example 1, and the results showed that the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com