Sol-gel method for preparing sub-micrometer level titanium carbide powder material

A technology of sol-gel method and titanium carbide powder is applied in the field of preparing sub-micron titanium carbide powder materials by sol-gel method, which can solve the problems of complex process flow, high production cost, unfavorable industrialized production and the like, and achieves the process flow Simple, low cost, easy to industrialize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Titanium dioxide, phenolic resin and methanol were mixed according to the molar ratio of 1:0.6:0.6, and stirred evenly by electromagnetic stirring, the stirring speed was 300 rpm, and the stirring time was 3 hours. Dry the mixed solution at 110° C. for 2 hours to obtain a titanium dioxide / phenolic resin precursor. The precursor was put into an alumina crucible, and under an argon protective atmosphere, the temperature was raised to 1600°C at a rate of 5°C / min, kept for 4 hours, and then lowered to room temperature at a rate of 5°C / min. % titanium carbide powder.

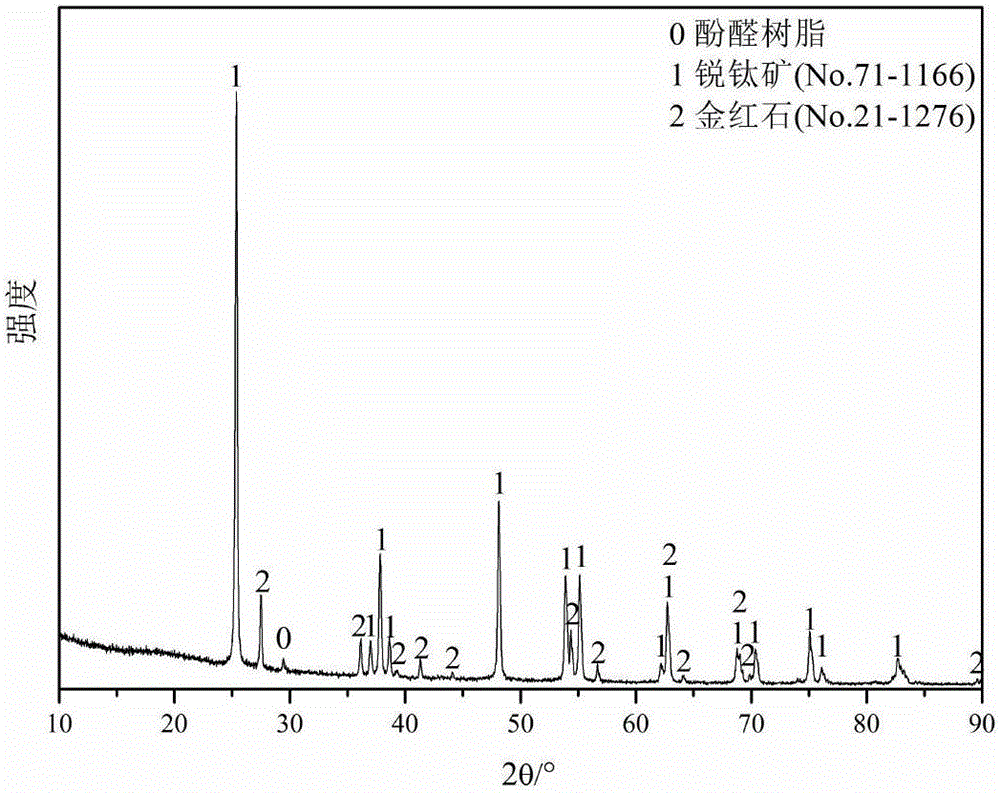

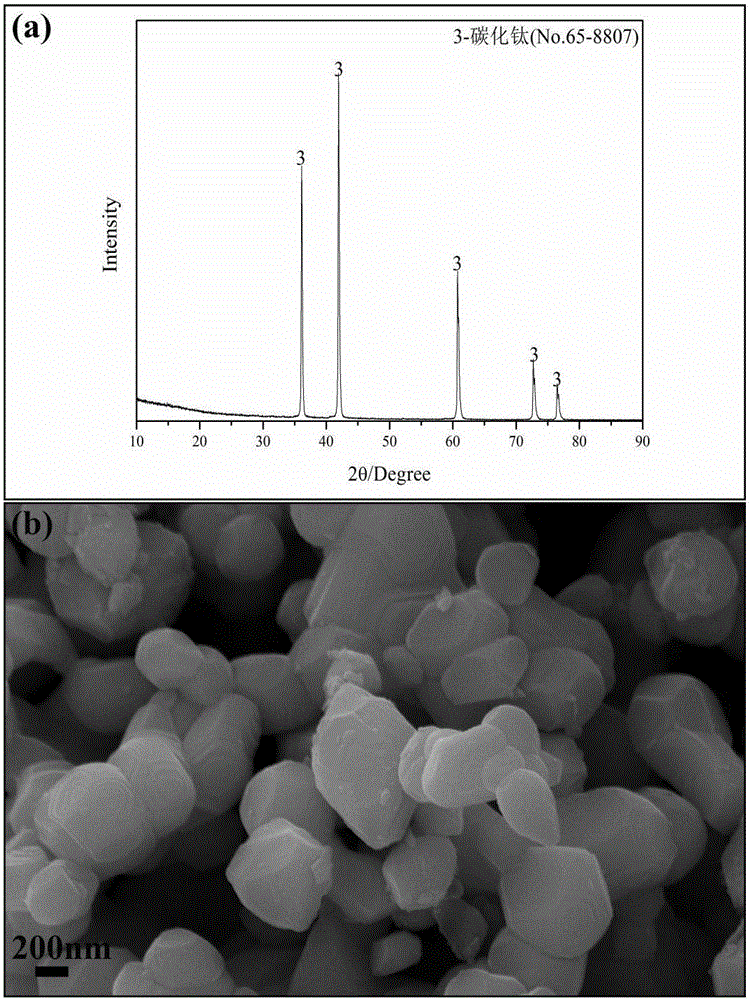

[0019] figure 1 is the X-ray diffraction pattern (XRD) of titanium dioxide / phenolic resin precursor, figure 2 (a) is the XRD pattern of the product when the carbothermal reduction temperature is 1600°C, which proves that the product is titanium carbide (PDF card number 65-8807) and there are no other impurity phases. figure 2 (b) is a scanning electron micrograph of titanium carbide. It can be ...

Embodiment 2

[0020] Example 2: Titanium dioxide, phenolic resin and methanol were mixed according to the molar ratio of 1:0.7:0.7, and stirred evenly by electromagnetic stirring, the stirring speed was 200 rpm, and the stirring time was 4 hours. The mixed solution was dried at 100° C. for 3 hours to obtain a titanium dioxide / phenolic resin precursor. The precursor was put into an alumina crucible, and under an argon protective atmosphere, the temperature was raised to 1500°C at a rate of 5°C / min, kept for 5 hours, and then lowered to room temperature at a rate of 5°C / min. % of titanium carbide powder, the particle size is about 500nm, and the size is uniform.

Embodiment 3

[0021] Example 3: Titanium dioxide, phenolic resin, and methanol were mixed according to a molar ratio of 1:0.7:0.7, and stirred evenly by electromagnetic stirring, with a stirring speed of 400 rpm and a stirring time of 2 hours. The mixed solution was dried at 90° C. for 4 hours to obtain a titanium dioxide / phenolic resin precursor. The precursor was put into an alumina crucible, and under an argon protective atmosphere, the temperature was raised to 1400°C at a rate of 5°C / min, kept for 6 hours, and then lowered to room temperature at a rate of 5°C / min. % of titanium carbide powder, the particle size is about 600nm, and the size is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com