Special fertilizer for corn

A special fertilizer for corn and nitrogen fertilizer technology, applied in the direction of application, nitrogen fertilizer, potassium fertilizer, etc., can solve the problems of short fertilizer effect period, corn nutrient stress, nutrient stress, etc., achieve long-lasting effect period, easy absorption and utilization, and activate growth and development performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

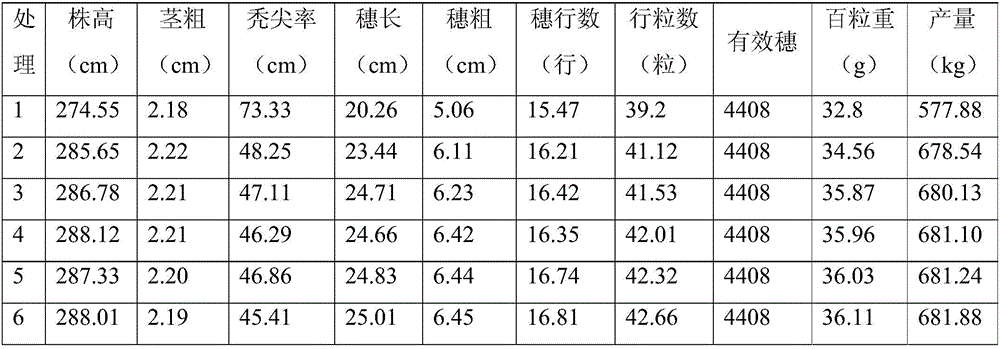

Examples

Embodiment 1

[0025] The special fertilizer for corn of the present invention is prepared from the following raw materials: 800kg of nitrogen fertilizer, 400kg of phosphate fertilizer, 500kg of potash fertilizer, 20kg of zinc fertilizer, 80kg of nitro humic acid, 10kg of organic trace elements, 5kg of inorganic trace elements, 15kg of medium trace elements, Material ash 15kg, lime powder 30kg;

[0026] The organic trace elements include 5kg tartrate-complexed copper, 5kg sucrose-complexed iron, 5kg sucrose-complexed zinc, 5kg sucrose-complexed manganese, 5kg sucrose-complexed magnesium, 2kg humic acid-complexed potassium, and humic acid-complexed magnesium 2kg, humic acid complexed zinc 2kg, humic acid complexed calcium 2kg, humic acid urea iron 2kg.

[0027] Described nitrogen fertilizer is 533kg organic nitrogen fertilizer and 267kg inorganic nitrogen fertilizer.

[0028] The organic nitrogen fertilizer is composted and fermented organic fertilizer, which is formed by decomposing and fer...

Embodiment 2

[0037] The special corn fertilizer of the present invention is prepared from the following raw materials: 900kg of nitrogen fertilizer, 450kg of phosphate fertilizer, 550kg of potash fertilizer, 30kg of zinc fertilizer, 90kg of nitro humic acid, 13kg of organic trace elements, 8kg of inorganic trace elements, 18kg of medium trace elements, Material ash 18kg, lime powder 40kg;

[0038] The organic trace elements include 10kg tartrate-complexed copper, 10kg sucrose-complexed iron, 10kg sucrose-complexed zinc, 10kg sucrose-complexed manganese, 10kg sucrose-complexed magnesium, 7kg humic acid-complexed potassium, and humic acid-complexed magnesium 7kg, humic acid complexed zinc 7kg, humic acid complexed calcium 7kg, humic acid urea iron 8kg.

[0039] Described nitrogen fertilizer is that 675kg organic nitrogen fertilizers and 225kg inorganic nitrogen fertilizers are mixed.

[0040] The organic nitrogen fertilizer is composted and fermented organic fertilizer, which is fermented f...

Embodiment 3

[0049] The special fertilizer for corn of the present invention is prepared from the following raw materials: 1000kg of nitrogen fertilizer, 500kg of phosphate fertilizer, 600kg of potassium fertilizer, 50kg of zinc fertilizer, 100kg of nitro humic acid, 15kg of organic trace elements, 10kg of inorganic trace elements, 20kg of middle trace elements, Material ash 20kg, lime powder 50kg;

[0050] The organic trace elements include 20kg of tartrate-complexed copper, 20kg of sucrose-complexed iron, 20kg of sucrose-complexed zinc, 20kg of sucrose-complexed manganese, 20kg of sucrose-complexed magnesium, 10kg of humic acid-complexed potassium, 10kg of humic acid-complexed magnesium 10kg, humic acid complexed zinc 10kg, humic acid complexed calcium 10kg, humic acid urea iron 10kg.

[0051]The nitrogen fertilizer is a mixture of 750kg organic nitrogen fertilizer and 250kg inorganic nitrogen fertilizer.

[0052] The organic nitrogen fertilizer is composted and fermented organic fertil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com