Acid-resistant, hydrogen-sulfide-resistant and wear-resistant flexible corrosion prevention coating and preparation method thereof

A technology of anti-corrosion coatings and hydrogen sulfide resistance, applied in the field of coatings, can solve problems such as the use of functional additives that cannot meet the needs of coatings, and achieve long-term effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

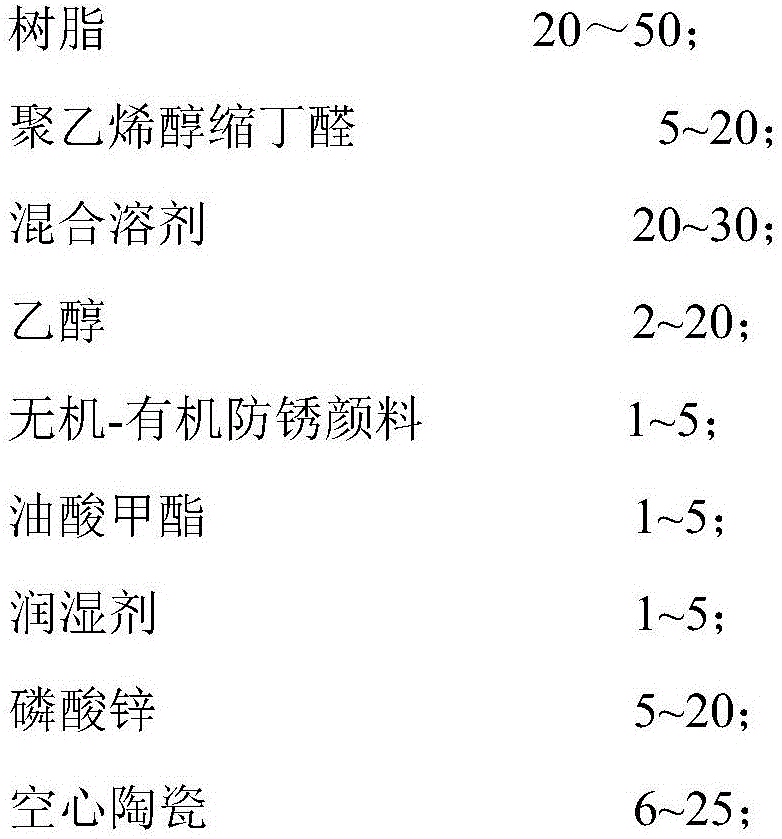

[0040] The composition of this coating is prepared according to the following component ratio (parts by weight):

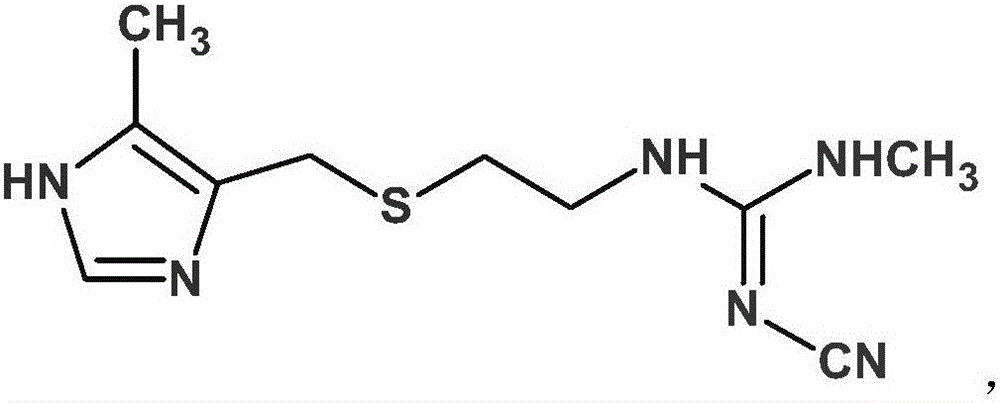

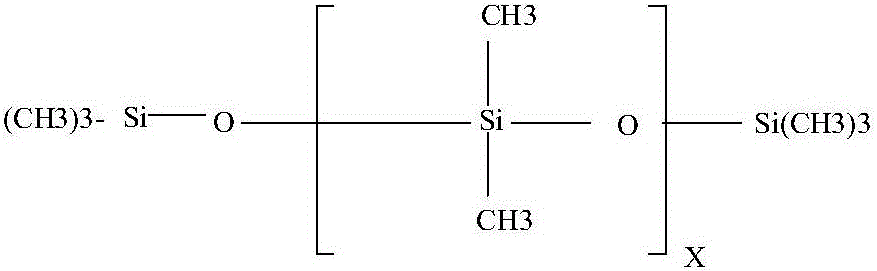

[0041] Component A: 25 parts of resin, 2 parts of wetting agent, 20 parts of polyvinyl butyral, 30 parts of mixed solvent, 8 parts of ethanol, 1 part of inorganic anti-rust and organic rust pigment, 1 part of methyl oleate, 5 parts of zinc phosphate Parts, 10 parts of hollow ceramics, wherein, the resin is a mixture of bisphenol A epoxy resin: polyurethane resin according to the mass ratio of 5: 3, and the mixed solvent is isophorone: pentanone: butyl acetate according to the mass ratio of 20: 5: 4, the average particle size of hollow ceramics is 5 microns, which is prepared by the following method: Al2O3 and SiO 2 The mixture of hollow ceramics, the mass ratio is 5:1; the wetting agent has the following structural formula:

[0042]

[0043] Wherein, X is 10.

[0044] Component B consists of triethylenediamine, H1 and H2 in a mass ratio of 8:1:2, wherein H1 i...

Embodiment 2

[0052] The composition of this coating is prepared according to the following component ratio (weight percentage):

[0053]Component A: 50 parts of resin, 3 parts of wetting agent, 12 parts of polyvinyl butyral, 21 parts of mixed solvent, 10 parts of ethanol, 2 parts of inorganic anti-rust and organic rust pigment, 1.5 parts of methyl oleate, 5.2 parts of zinc phosphate Parts, 8.3 parts of hollow ceramics, wherein, resin is the mixture of bisphenol A epoxy resin, polyurethane resin: bisphenol F epoxy resin=10: 2: 5, and mixed solvent is isophorone: pentanone: butyl acetate : Ethylene glycol butyl ester is a mixture of 20:5:2:1 by mass ratio, and the average particle diameter of hollow ceramics is 5 microns, which is prepared by the following method: Al2O3 and SiO 2 The mixture of hollow ceramics has a mass ratio of 8:1; the wetting agent has the following structural formula: where X is 15.

[0054]

[0055] Component B consists of triethylenediamine, H1 and H2 in a mass ra...

Embodiment 3

[0063] Component A: 50 parts of resin, 5 parts of wetting agent, 20 parts of polyvinyl butyral, 20 parts of mixed solvent, 9 parts of ethanol, 5 parts of inorganic anti-rust and organic rust pigment, 5 parts of methyl oleate, 5 parts of zinc phosphate Parts, 6 parts of hollow ceramics, wherein the resin is epoxy phenolic resin, and the mixed solvent is a mixture of isophorone: pentanone: butyl acetate: ethylene glycol butyl ester in a mass ratio of 20:5:2:1, and the hollow The average particle size of the ceramic is 5 microns, which is prepared by the following method: Al2O3 and SiO 2 The mixture of hollow ceramics, the mass ratio is 6:1; the wetting agent has the following structural formula:

[0064]

[0065] Wherein, X is 5.

[0066] Component B consists of triethylenediamine, H1 and H2 in a mass ratio of 9:1:2, where H1 is

[0067]

[0068] Wherein, R is OH, and A / B=10 / 1.

[0069] The above-mentioned components are mixed according to the formula amount, and then g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com