Acid-resistant heatproof elastic bonding agent and preparation method thereof

An elastic sticky, temperature-resistant technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of chemical anti-corrosion materials that cannot take into account acid resistance, temperature resistance, high elasticity and adhesion, etc. problems, to achieve the effects of easy industrial production, good acid resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

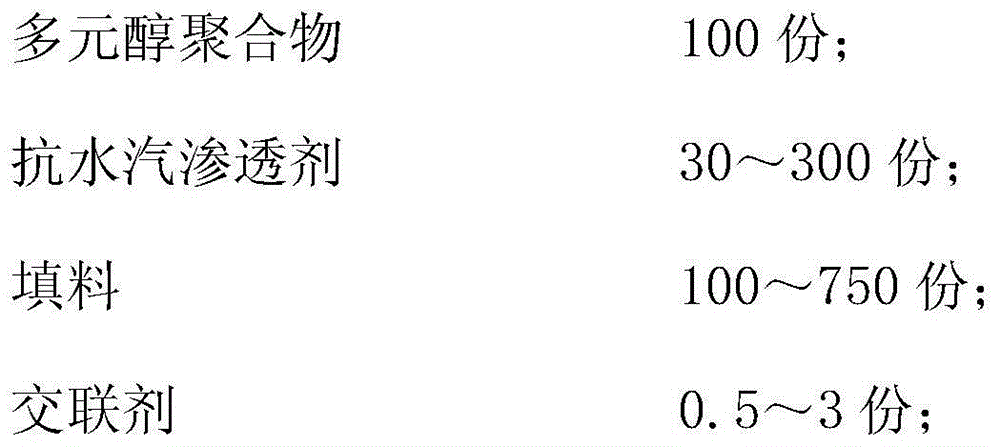

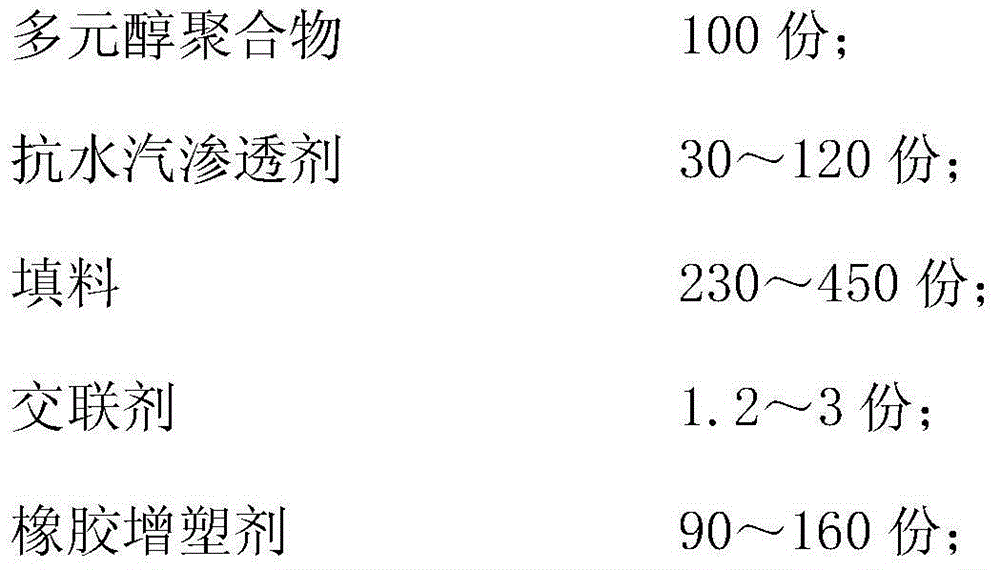

[0041] Raw materials of acid-resistant and temperature-resistant elastic adhesive:

[0042] A component raw materials:

[0043]Polyol polymer: 50 parts of hydroxyl-terminated polyester with a molecular weight of 3800, 30 parts of hydroxyl-terminated polyether with a molecular weight of 2500, and 20 parts of hydroxyl-terminated polybutadiene with a molecular weight of 4000;

[0044] Anti-moisture penetration agent: 20 parts of styrene-butadiene rubber, 10 parts of isoprene rubber;

[0045] Filler: 125 parts of kaolin, 100 parts of bentonite, 145 parts of mica powder;

[0046] Cross-linking agent: 3 parts of glycerol;

[0047] Rubber plasticizer: 20 parts naphthenic oil, 125 parts aromatic oil;

[0048] B component raw materials:

[0049] Polyisocyanate: 70 parts of 1,6-hexamethylene diisocyanate, 30 parts of dimethylene phenyl diisocyanate;

[0050] Rubber plasticizer: 15 parts of paraffin oil, 25 parts of rubber oil;

[0051] Catalyst: 0.025 parts of dibutyltin dilaurate...

Embodiment 2

[0054] Raw materials of acid-resistant and temperature-resistant elastic adhesive:

[0055] A component raw materials:

[0056] Polyol polymer: 50 parts of hydroxyl-terminated polyether with molecular weight of 8000, 50 parts of hydroxyl-terminated polyurethane with molecular weight of 2000;

[0057] Anti-moisture penetration agent: 150 parts of butyl rubber, 100 parts of nitrile rubber, 50 parts of petroleum asphalt;

[0058] Filler: 50 parts of silica powder, 150 parts of bentonite, 30 parts of carbon black;

[0059] Crosslinking agent: 0.5 parts of 1,2-propanediol, 1.5 parts of pentaerythritol;

[0060] Rubber plasticizer: 15 parts of naphthenic oil, 5 parts of rubber oil;

[0061] B component raw materials:

[0062] Polyisocyanate: 100 parts of toluene diisocyanate;

[0063] Rubber plasticizer: 20 parts naphthenic oil;

[0064] Catalyst: 0.667 parts of dibutyl tin dioctoate;

[0065] The preparation method of the acid-resistant and heat-resistant elastic adhesive: A...

Embodiment 3

[0067] Raw materials of acid-resistant and temperature-resistant elastic adhesive:

[0068] A component raw materials:

[0069] Polyol polymer: 100 parts of hydroxyl-terminated polyester with a molecular weight of 1000;

[0070] Anti-moisture penetration agent: 30 parts of butyl rubber;

[0071] Filler: 300 parts of kaolin, 200 parts of bentonite, 50 parts of mica powder, 200 parts of carbon black;

[0072] Crosslinking agent: 0.5 parts of 1,6-hexanediol;

[0073] Rubber plasticizer: 150 parts naphthenic oil, 50 parts aromatic oil;

[0074] B component raw materials:

[0075] Polyisocyanate: 50 parts of benzhydryl-4,4'-diisocyanate, 30 parts of tetramethyl diisocyanate; 20 parts of isophorone diisocyanate;

[0076] Rubber plasticizer: 40 parts of paraffin oil;

[0077] Catalyst: 0.04 parts of stannous octoate;

[0078] The preparation method of the acid-resistant and heat-resistant elastic adhesive: add the raw materials of component A into an 80°C vacuum kneader and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com