Full-temperature-process pressure swing adsorption purification method for benzene removal and naphthalene removal of coke oven gas

A technology of pressure swing adsorption and coke oven gas, which is applied in combustible gas purification, combustible gas purification/transformation, removal of gas pollutants, etc., can solve the problem of large consumption of regeneration gas and heat, difficulty in matching adsorption time, and reduction of fuel heat Value and other issues, to avoid the negative impact of desulfurization and deammonization load and efficiency, reduce energy consumption and other impurity interference, and reduce the treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

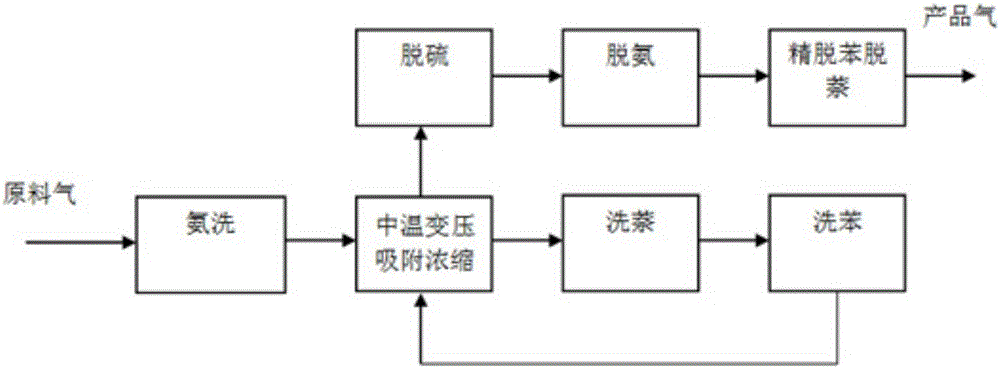

[0042] like figure 1 As shown, a full-temperature PSA purification method for removing benzene and naphthalene from coke oven gas, the following operations are performed in sequence:

[0043] (1) Ammonia washing process:

[0044] Use the circulating ammonia water pump to send the circulating ammonia water with a temperature of about 70°C and a pressure of 2.3-2.6MPa to the gas collecting pipe for spraying, and reduce the temperature of the high-temperature raw material coke oven gas (hereinafter referred to as "coal gas") from 650-800°C to 80 ~100°C; with the cooling of the gas, 65-70% of coal tar and part of benzene in the gas are condensed, and the tar is about 80-120g / m 3 Reduced to about 30~35g / m 3 , benzene from 30 to 45g / m 3 Reduced to 3.5 ~ 4g / m 3 Below, naphthalene ranges from 8 to 12g / m 3 down to 1g / m 3 the following.

[0045] (2) Medium temperature pressure swing adsorption concentration process:

[0046] Alternate cycle operation is carried out in the medium-t...

Embodiment 2

[0066] According to the basic process of Example 1, the temperature of the high-temperature gas after ammonia washing is 60-80°C, the pressure is 2.6-2.8MPa, 70-75% of coal tar and part of benzene in the gas are condensed, and the tar is from about 80-120g / m 3 Reduced to about 35~40g / m 3 , benzene from 30 to 45g / m 3 Reduced to 3~3.5g / m 3 Below, naphthalene ranges from 8 to 12g / m 3 down to 0.8g / m 3 the following. The coal gas enters the medium temperature pressure swing adsorption concentration process under the corresponding operating conditions for adsorption concentration, debenzene and naphthalene removal, etc. At this time, the intermediate gas flows out from the top of the adsorption tower, and the tar contained therein drops to 20-30 mg / m 3 , benzene dropped to 20~30mg / m 3 , naphthalene reduced to 0.1g / m 3 Next, the intermediate gas is purified in the next step; the concentrated gas with a benzene and naphthalene concentration of about 55-60% is obtained by deso...

Embodiment 3

[0068]On the basis of Example 2, the desorbed gas (concentrated gas) obtained from the medium temperature pressure swing adsorption concentration process directly enters the debenzene section, and a tower process is adopted to remove benzene by distillation, washing oil (rich oil) and concentrated gas respectively. It enters the middle part of the debenzene tower at 170-190 ° C, and the enriched light benzene and rich oil flow out from the top of the tower. Extract the refined heavy benzene at 120-130°C from the middle layer of the feed inlet (16 layers), and extract the enriched naphthalene oil at 150-160°C between the lower layer of the refined heavy benzene layer and the upper part of the oil-rich feed layer, and enter the final cooling and washing process. Oil and naphthalene separation tank, the product naphthalene and lean oil, the lean oil and the lean oil flowing out from the bottom of the debenzene tower enter the lean oil tank, after heat exchange and oil washing rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com