Method for preparing in-situ carbon coated manganese carbonate for negative electrode of lithium ion battery

A technology of carbon-coated manganese carbonate and carbon-coated manganese carbonate materials, which are applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of improving cycle stability, low production cost, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Prepare a potassium permanganate solution with a concentration of 0.25 mol / L, stir and disperse;

[0030] (2) Prepare 0.1 mol / L glucose solution, stir and disperse;

[0031] (3) Add the above-mentioned glucose solution to the potassium permanganate solution, stir and disperse, and ultrasonic treatment 22 Hz, the treatment time is 5 minutes;

[0032] (4) Add the dispersed solution to the reactor and heat it to 180°C for 6 hours;

[0033] (5) The heated reactor is naturally cooled to room temperature, cleaned, and dried to obtain a powder.

[0034] Get the powder test results:

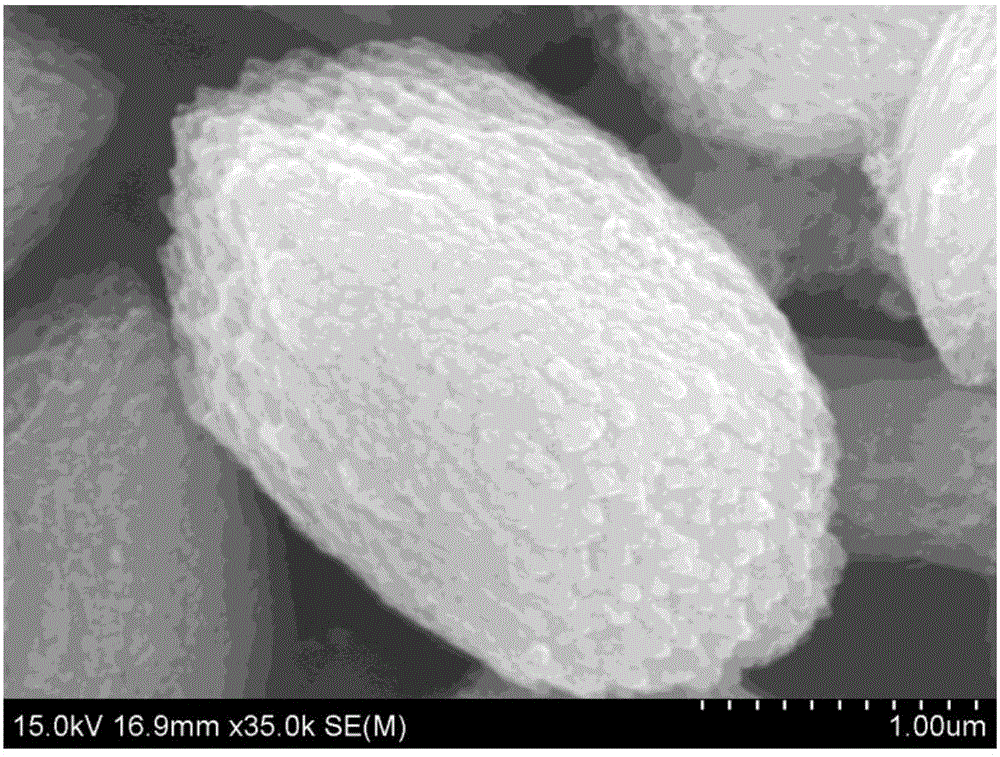

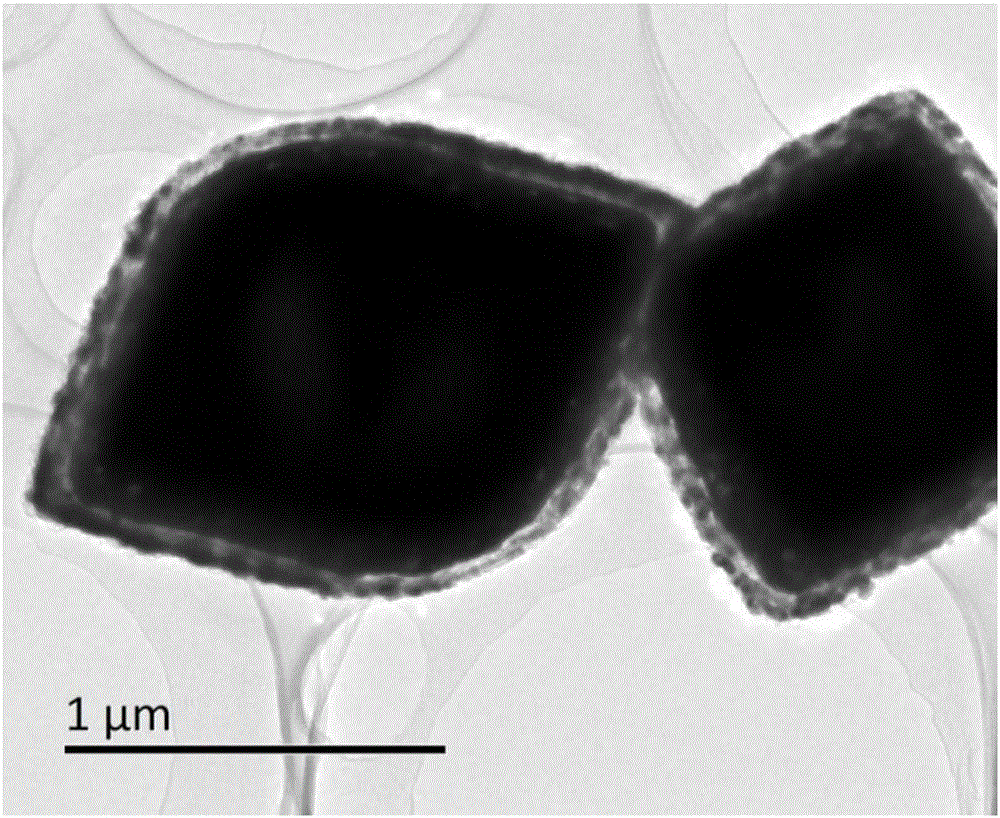

[0035] SEM topography like figure 1 As shown in the figure, the carbon-coated manganese carbonate crystal is in the shape of a spindle, the surface carbon layer is evenly coated, and the crystal size distribution is uniform; the TEM appearance is as figure 2 As shown, the carbon-coated manganese carbonate crystals are in the shape of a spindle. It can be clearly seen that the manganese carbonate crystal...

Embodiment 2

[0038] (1) Prepare a potassium permanganate solution with a concentration of 0.04 mol / L, stir and disperse;

[0039] (2) Prepare 0.02 mol / L oxalic acid solution, stir and disperse;

[0040] (3) Add the above-mentioned oxalic acid solution to the potassium permanganate solution, stir and disperse, ultrasonic treatment 15Hz, the treatment time is 20 minutes;

[0041] (4) Add the dispersed solution to the reaction kettle and heat to 120°C for 10 hours;

[0042] (5) The heated reactor is naturally cooled to room temperature, cleaned, and dried to obtain a powder.

[0043] Get the powder test results:

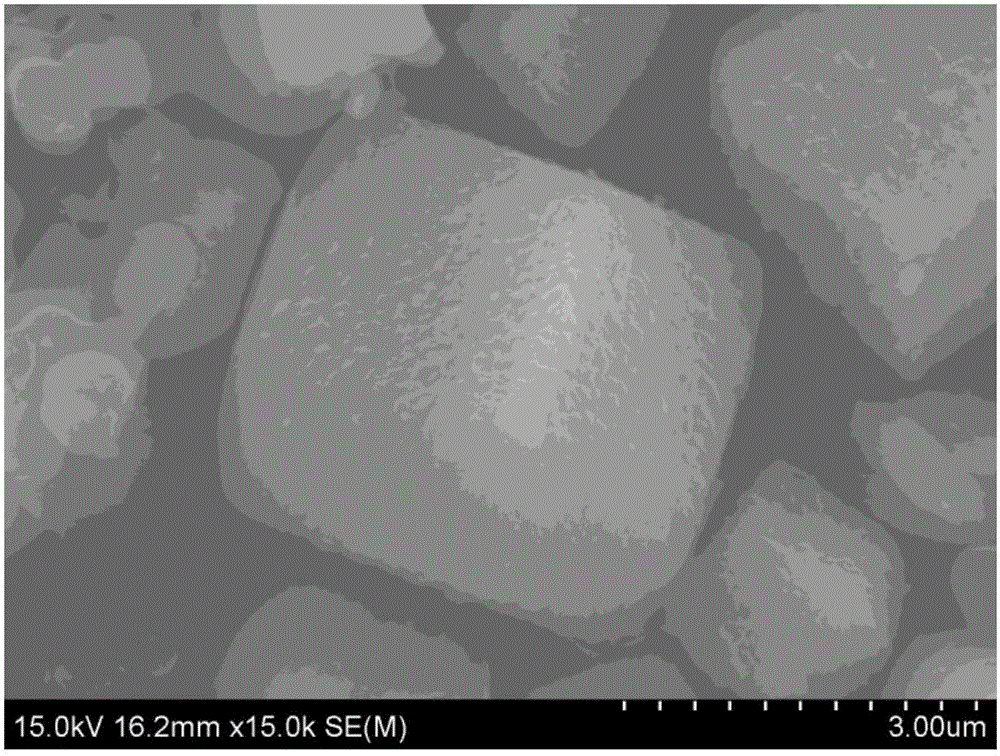

[0044] SEM topography like image 3 As shown in the figure, the carbon-coated manganese carbonate crystal is a square with a regular shape, the surface carbon layer is evenly coated, and the crystal size distribution is uniform; the TEM appearance is as Figure 4 As shown, the carbon-coated manganese carbonate crystal presents a square with a regular shape. It can be clearly seen that the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com