Preparation method of isobutyl vinyl ether

A technology of isobutyl vinyl ether and isobutanol, which is applied in the direction of ether preparation, unsaturated compound addition to ether, ether separation/purification, etc., can solve the problem of low gas-liquid mass transfer efficiency in spray tower, reactor transfer, etc. Problems such as poor thermal effect and large amount of catalyst are used to achieve the effect of increasing the gas-liquid mass transfer rate, reducing the amount of catalyst, and increasing the gas holdup rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

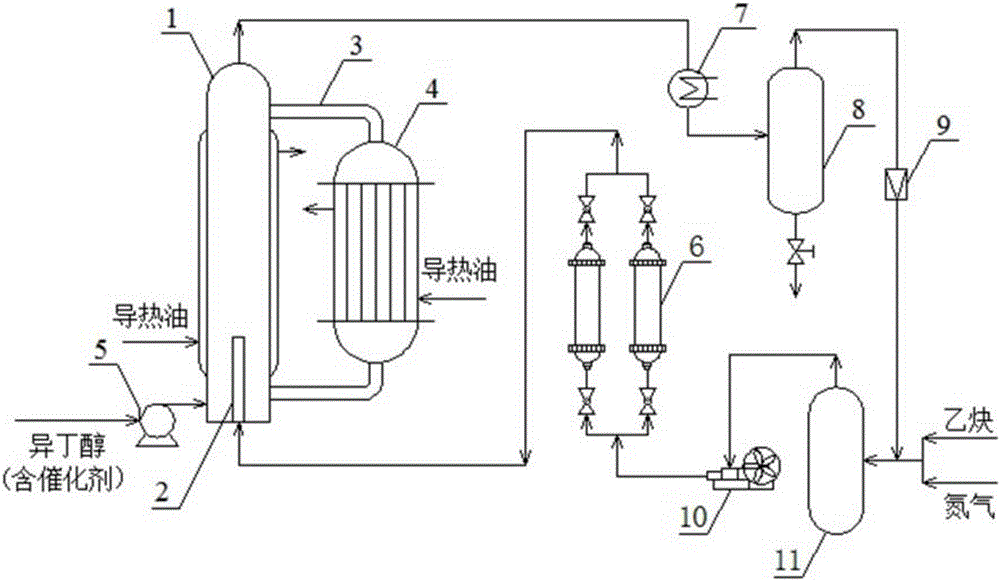

[0021] The reaction of acetylene and isobutanol uses figure 1 The reaction setup shown. The riser of the loop reactor has an inner diameter of 0.15m and a height of 2.5m. The gas injector is a single-head multi-hole nozzle with a diameter of 3 μm. The process operating conditions are as follows:

[0022] Catalyst dosage: 2% of the mass of isobutanol;

[0023] Isobutanol (catalyst-containing) feed flow rate 16L / h;

[0024] Mixed gas feed flow rate 15Nm 3 / h;

[0025] The volume fraction of acetylene in the feed mixed gas is 60%;

[0026] Heat exchanger temperature: 150°C;

[0027] Reaction pressure: 0.5MPa;

[0028] Results The one-pass conversion rate of isobutanol was 88%, and the selectivity of reaction to isobutyl vinyl ether was 95.5%.

Embodiment 2

[0030] The reaction of acetylene and isobutanol with figure 1 The reaction setup shown. The riser of the loop reactor has an inner diameter of 0.15m and a height of 2.5m. The gas injector is a single-head multi-hole nozzle with a pore size of 10 μm. The process operating conditions are as follows:

[0031] Catalyst dosage: 3% of the mass of isobutanol;

[0032] Isobutanol (catalyst-containing) feed flow rate 16L / h;

[0033] Mixed gas feed flow rate 15Nm 3 / h;

[0034] The volume fraction of acetylene in the feed mixed gas is 70%;

[0035] Heat exchanger temperature: 140°C;

[0036] Reaction pressure: 0.6MPa;

[0037] Results The single-pass conversion rate of isobutanol was 85.7%, and the selectivity of the reaction to isobutyl vinyl ether was 97%.

Embodiment 3

[0039] The reaction of acetylene and isobutanol with figure 1 The reaction setup shown. The riser of the loop reactor has an inner diameter of 0.15m and a height of 2.5m. The gas injector is a double-ended multi-hole nozzle with a pore diameter of 5 μm. The process operating conditions are as follows:

[0040] Catalyst consumption: 5% of the mass of isobutanol;

[0041] Isobutanol (catalyst-containing) feed flow rate 16L / h;

[0042] Mixed gas feed flow rate 15Nm 3 / h;

[0043] The volume fraction of acetylene in the feed mixed gas is 65%;

[0044] Heat exchanger temperature: 160°C;

[0045] Reaction pressure: 0.8MPa;

[0046] As a result, the single-pass conversion of isobutanol was 92%, and the selectivity of the reaction to isobutyl vinyl ether was 95%.

[0047] The invention provides a method for preparing isobutyl vinyl ether with good mass and heat transfer effect, simple device structure, safety and high efficiency, simple operation, low cost and easy industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com