Preparation method of polymer/ZnO/SiO2 nano-composite microspheres

A nanocomposite and polymer technology, applied in the field of nanocomposite microsphere preparation, can solve the problems of easy agglomeration and poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

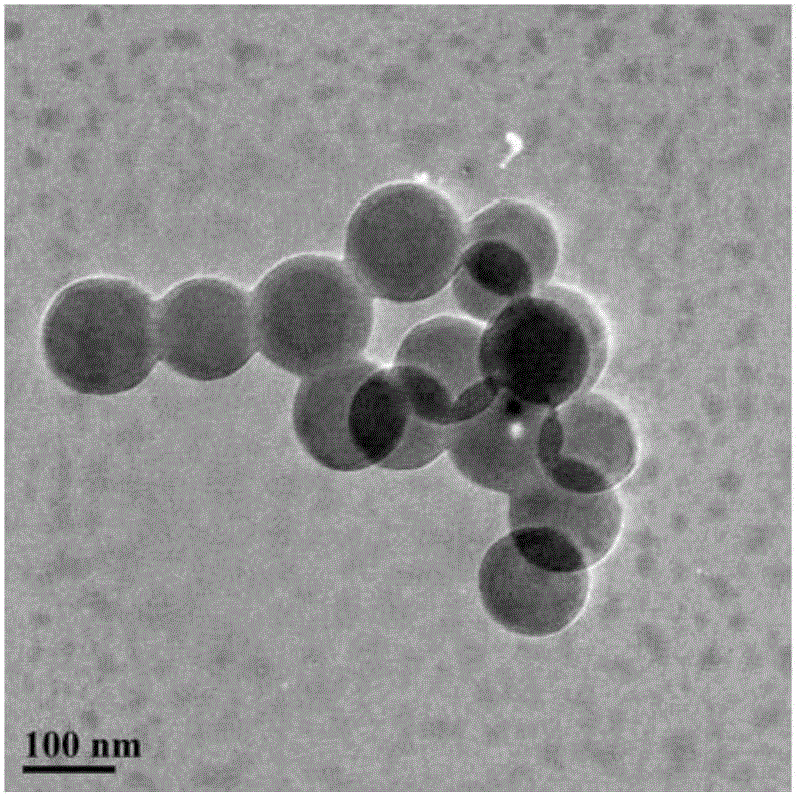

[0039] Weigh 0.1g SDS, 0.1g sodium bicarbonate, 0.1g sodium dihydrogen phosphate, dilute with 90g deionized water, and transfer to a 250ml four-necked bottle equipped with a stirring device, a thermometer and a reflux condensing device (component A); Take 7.5g of styrene monomer, 2.5g of 3-methacrylic acid propyltrimethoxysilane (MEMO), 0.5g of HD, 0.1g of AIBN (component B), stir well and transfer to the dropping funnel. Slowly add component B to component A dropwise at room temperature, and continue to stir for 0.5h to emulsify after the addition. Take out the above mixed components and ultrasonically fine emulsify for 10min. Continue to transfer to a 250ml four-necked flask equipped with a stirring device, a thermometer and a reflux condensing device, slowly increase the temperature to 70°C, and polymerize for 3 hours to prepare PS microspheres with silicon hydroxylation on the surface, and the morphology of the microspheres is as follows: figure 1 shown.

[0040] Take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com