Adhesive tape preparation method

A technology of tape and weight, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problem that the adhesive is easy to adhere to the surface of the object, the adhesive has poor adhesion, and the residual adhesive, etc. problem, to reduce the degumming phenomenon, improve the adhesion, and achieve the effect of good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

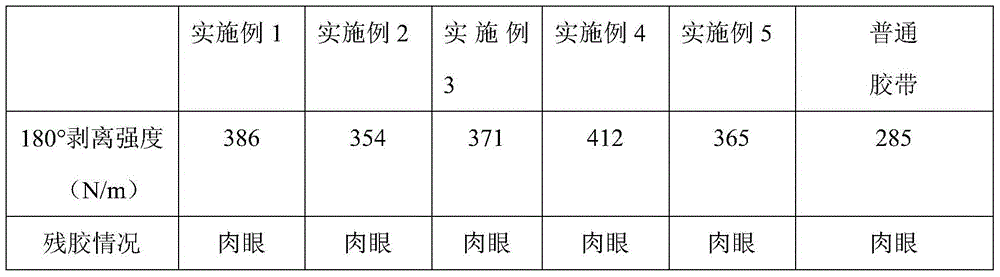

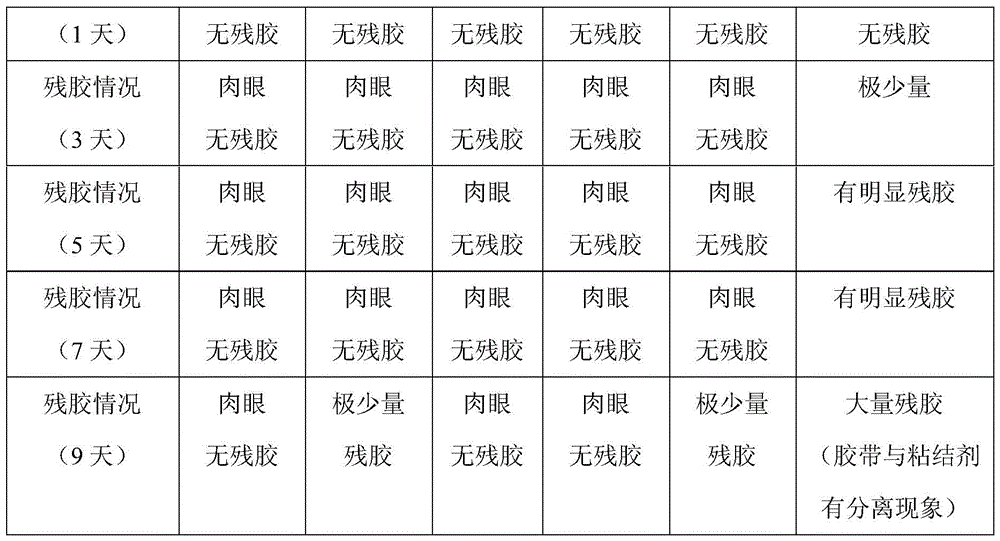

Examples

Embodiment 1

[0026] A kind of preparation method of adhesive tape is characterized in that, comprises the following steps:

[0027] (1) 60 parts by mass of extinction PVC, 20 parts by mass of HMWPVC with a degree of polymerization of 2500, 1 part by mass of plant fiber powder with a particle diameter of 1.8 μm, polyvinyl alcohol of 0.8 parts by mass, 15 parts by mass of phthalic acid Diisononyl, 10 parts by mass of paraffin, stirred evenly, heated to 80°C for 2 hours, then heated to 100°C for 3 hours, extracted paraffin with amyl acetate, dried and rolled to form a film, and the film was soaked in ethanol After drying for 30 minutes, apply acrylic acid and benzophenone with a concentration of 30% on the surface, and irradiate for 30 seconds under a 1000W ultraviolet high-pressure mercury lamp to obtain a substrate;

[0028] (2) Coating the adhesive on one side of the base material obtained in step 1, and drying;

[0029] (3) Paste the release film on the other side of the base material, a...

Embodiment 2

[0031] A kind of preparation method of adhesive tape is characterized in that, comprises the following steps:

[0032] (1) 80 parts by mass of matt PVC, 30 parts by mass of HMWPVC with a degree of polymerization of 2500, 2 parts by mass of protein fiber powder with a particle diameter of 2 μm, polyvinyl alcohol of 0.5 parts by mass, 3 parts by mass of phthalic acid Isononyl ester, 7 parts by mass of dibutyl phthalate, and 20 parts by mass of paraffin are stirred evenly, heated to 80°C for 1 hour, then heated to 95°C for 2 hours, and lauric acid is used to extract the paraffin, dried and then calendered. Form a film, soak the film in ethanol for 40 minutes, smear acrylic acid and benzophenone with a concentration of 30% on the surface after drying, and irradiate for 40 seconds under a 1100W ultraviolet high-pressure mercury lamp to obtain a substrate;

[0033] (2) Coating the adhesive on one side of the base material obtained in step 1, and drying;

[0034] (3) Paste the relea...

Embodiment 3

[0036] A kind of preparation method of adhesive tape is characterized in that, comprises the following steps:

[0037] (1) With 70 parts by mass of matt PVC, 25 parts by mass of HMWPVC with a degree of polymerization of 2800, 2 parts by mass of protein fiber powder with a particle diameter of 2.3 μm, polyvinyl alcohol of 0.7 parts by mass, 13 parts by mass of phthalic acid Diisodecyl ester, after stirring 15 parts by mass of paraffin evenly, heated to 76°C for 1 hour, then heated to 95°C for 2 hours, extracted the paraffin with chloroform, dried and rolled to make a film, the film was soaked in ethanol for 50 minutes, After drying, smear acrylic acid and benzophenone with a concentration of 50% on the surface, and irradiate it under a 1100W ultraviolet high-pressure mercury lamp for 50s to obtain a substrate;

[0038] (2) Coating the adhesive on one side of the base material obtained in step 1, and drying;

[0039] (3) Paste the release film on the other side of the base mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com