Method of adsorbing and separating palladium with high-molecular-based pillararene

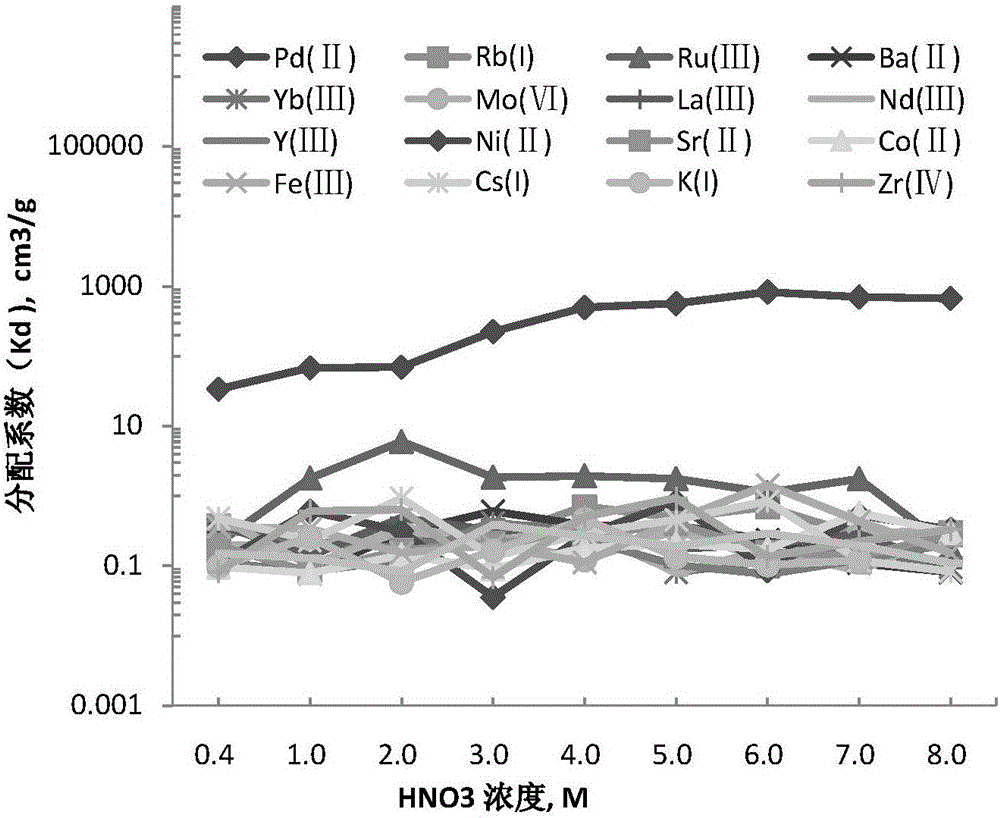

An adsorption separation, polymer-based technology, applied in chemical instruments and methods, improvement of process efficiency, and other chemical processes, can solve the problems of long radioactive cycle, high content, and great harm, and achieve fast separation speed and selectivity Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

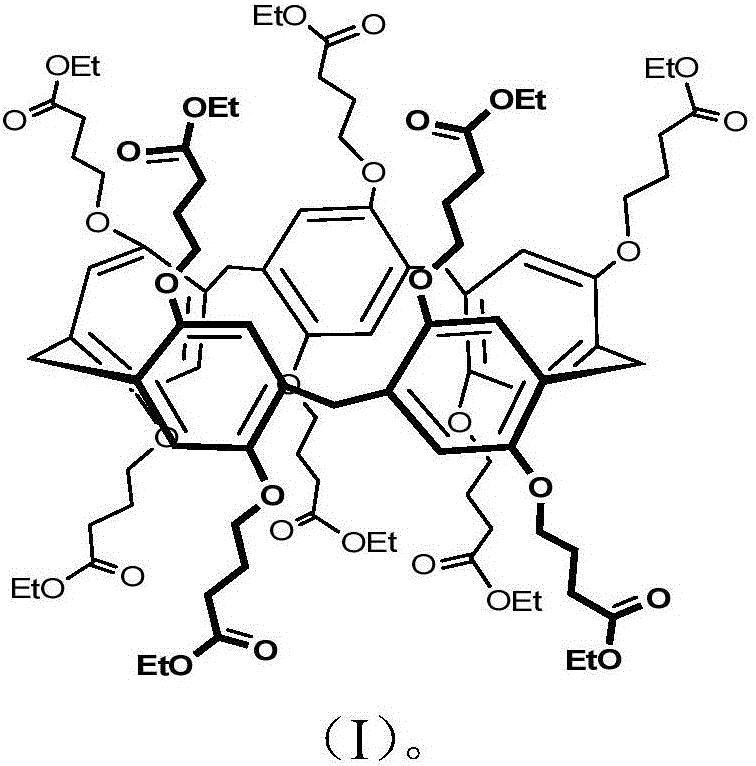

[0034] A preparation method of pillar arene derivatives, comprising:

[0035] (1) 1,4-p-methoxybenzene and paraformaldehyde are reacted under the conditions of boron trifluoride ether as a catalyst and dry dichloromethane or 1,2-dichloroethane as a solvent to obtain permethoxy Pillar[5]arenes.

[0036] Wherein, the molar ratio of 1,4-p-methoxybenzene and paraformaldehyde is 1:1, the molar ratio of 1,4-p-methoxybenzene and catalyst boron trifluoride ether is 1:1, and the reaction temperature is 28°C, the reaction time is 3 minutes, and the amount of solvent used is 5 mL per mmoL of 1,4-p-methoxybenzene.

[0037] (2) Using the permethoxypyrro[5]arene obtained in step (1) as a raw material, react with boron tribromide under the condition of dry chloroform as a solvent to obtain perhydroxypyrro[5]arene.

[0038] Wherein, the molar ratio of permethoxycolumn[5]arene to boron tribromide is 1:20, the reaction temperature is 25°C, the reaction time is 2 days, and the amount of solven...

Embodiment 2

[0043] The commercially available ion exchange resin XAD-7 is activated as follows:

[0044] Weigh a certain amount of commercially available product XAD-7 into a 250mL round-bottomed flask, add an appropriate amount of methanol, stir at room temperature for 24 hours and then filter with suction. Store in a dry box.

Embodiment 3

[0046] Weigh 2.5g of the compound prepared in Example 1 in a 250mL round-bottomed flask, add 150mL of dichloromethane, add 10g of XAD-7 activated in Example 2 under stirring, move the system into a water bath, and place in a rotary evaporator After rotating and stirring at 45 °C for 120 min, the temperature was raised to 65 °C, and rotating and stirring for 180 min until the mixture was a loose powder. During this process, the perbutyrate-substituted pillar[5]arene derivatives entered the pores of the XAD-7 support by capillary action, and were finally vacuum-dried at 45 °C overnight to obtain a pink, loose adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com