Graphene activated metal organic framework electrode material and preparation and applications thereof

A technology for electrode materials and activated metals, applied in the field of electrochemical materials, can solve problems such as low energy density and poor electrical conductivity of materials, and achieve the effects of high energy density, excellent electrical conductivity, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

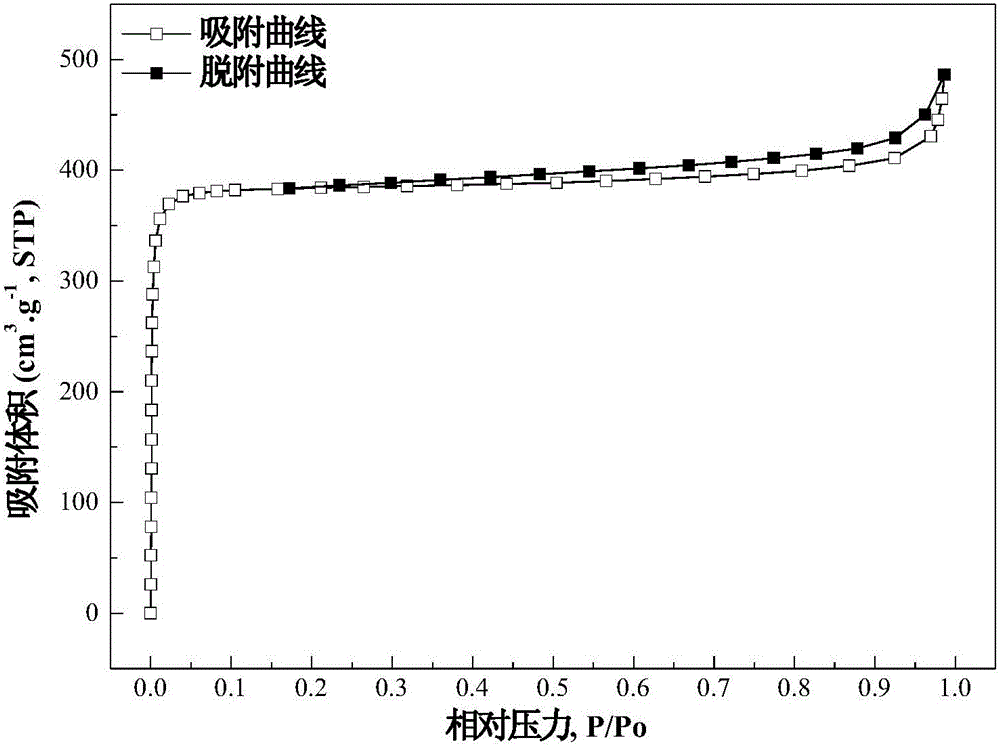

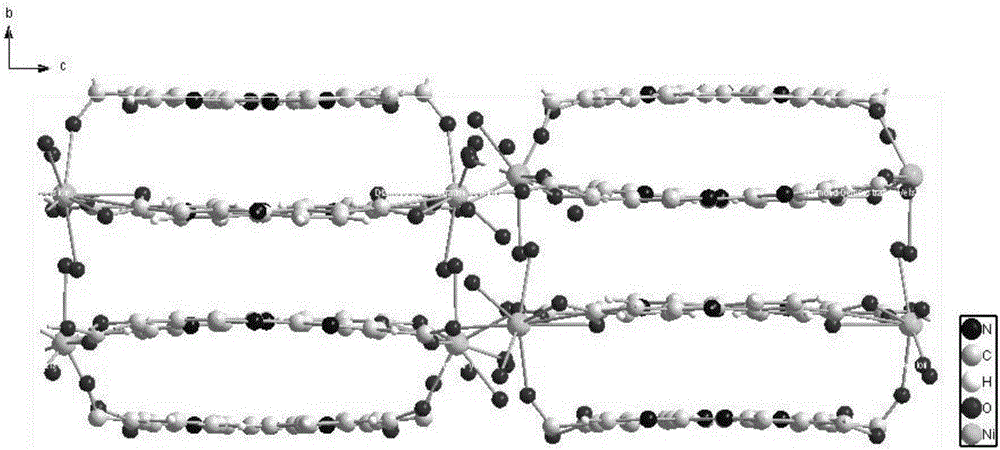

[0027] Weigh 1mmol of nickel acetate, 1mmol of 2,2'-bipyridine-4,4'-dicarboxylic acid organic ligand and 50mL of DMF solution, stir evenly, transfer to the reaction kettle, keep the reaction temperature at 120°C for 24h, and wash by centrifugation , dried under vacuum at 85°C to obtain the Ni-MOF structure material, which passed the test of N 2 The adsorption-desorption isotherm obtained BET is 1869m 2 / g. Such as figure 2 As shown, the crystal structure diagram of Ni-MOF along the [100] direction, it can be seen that the organic ligands of 2,2'-bipyridyl-4,4'-dicarboxylic acid stack parallel to the (010) crystal plane, and Nickel acetate is strongly complexed.

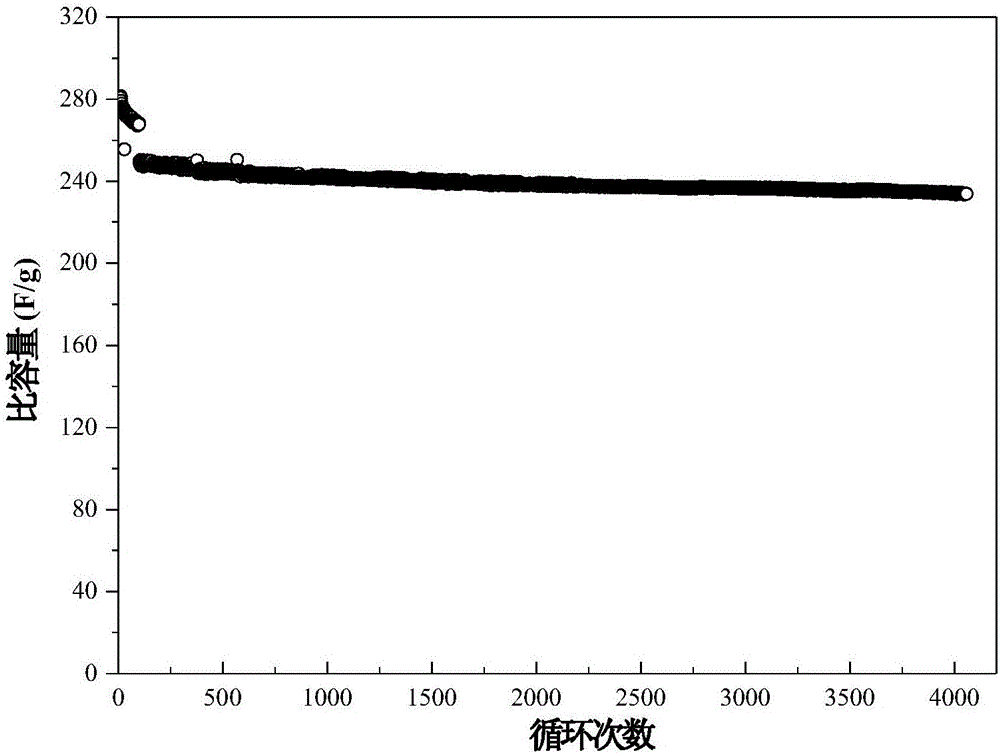

[0028] Weigh 2.0g of the above-mentioned Ni-MOF structure material into a beaker, add 40mL of deionized water for ultrasonic dispersion (ultrasonic power and frequency are 100W and 40kHz, respectively), then add 100mg of graphene, ultrasonically react for 30min, and wash and dry to obtain Graphene activated metal...

Embodiment 2

[0034] Weigh 1mmol of cobalt acetate, 1mmol of 2,2'-bipyridine-4,4'-dicarboxylic acid organic ligand and 50mL of DMF solution, stir evenly, transfer to the reaction kettle, keep the reaction temperature at 120°C for 24h, and wash by centrifugation , dried under vacuum at 85°C to obtain the Co-MOF structure material.

[0035] Weigh 2.0g of the above-mentioned Co-MOF structure material into a beaker, add 40mL of deionized water for ultrasonic dispersion (ultrasonic power and frequency are 100W and 40kHz, respectively), then add 20mg of graphene, ultrasonically react for 30min, and wash and dry to obtain Graphene activated metal organic framework electrode material GNS--Co-MOF.

[0036] The GNS--Co-MOF electrode material, binder and conductive carbon black were uniformly dispersed in NMP according to the mass ratio of 85:10:5, and then the electrode slurry was applied to the foamed nickel by a roller machine, using 3M KOH aqueous solution is used as the electrolyte to assemble t...

Embodiment 3

[0039] Weigh 1mmol of copper acetate, 2mmol of 2,2'-bipyridine-4,4'-dicarboxylic acid organic ligand and 50mL of NMP solution, stir evenly, transfer to the reaction kettle, keep the reaction temperature at 120°C for 24h, and centrifuge and wash , dried under vacuum at 85°C to obtain the Cu-MOF structure material.

[0040]Weigh 2.0g of the above Cu-MOF structure material into a beaker, add 40mL of deionized water for ultrasonic dispersion (ultrasonic power and frequency are 100W and 40kHz, respectively), and then add 40mg of graphene oxide GO (mass fraction of graphene oxide solution 1.0%), ultrasonically reacted for 30min, and was washed and dried to obtain graphene-activated metal-organic framework electrode material GO—Cu-MOF.

[0041] The GO--Cu-MOF electrode material, binder and conductive carbon black were uniformly dispersed in NMP according to the mass ratio of 85:10:5, and then the electrode slurry was applied to the foamed nickel by a double roller machine, using 3M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com