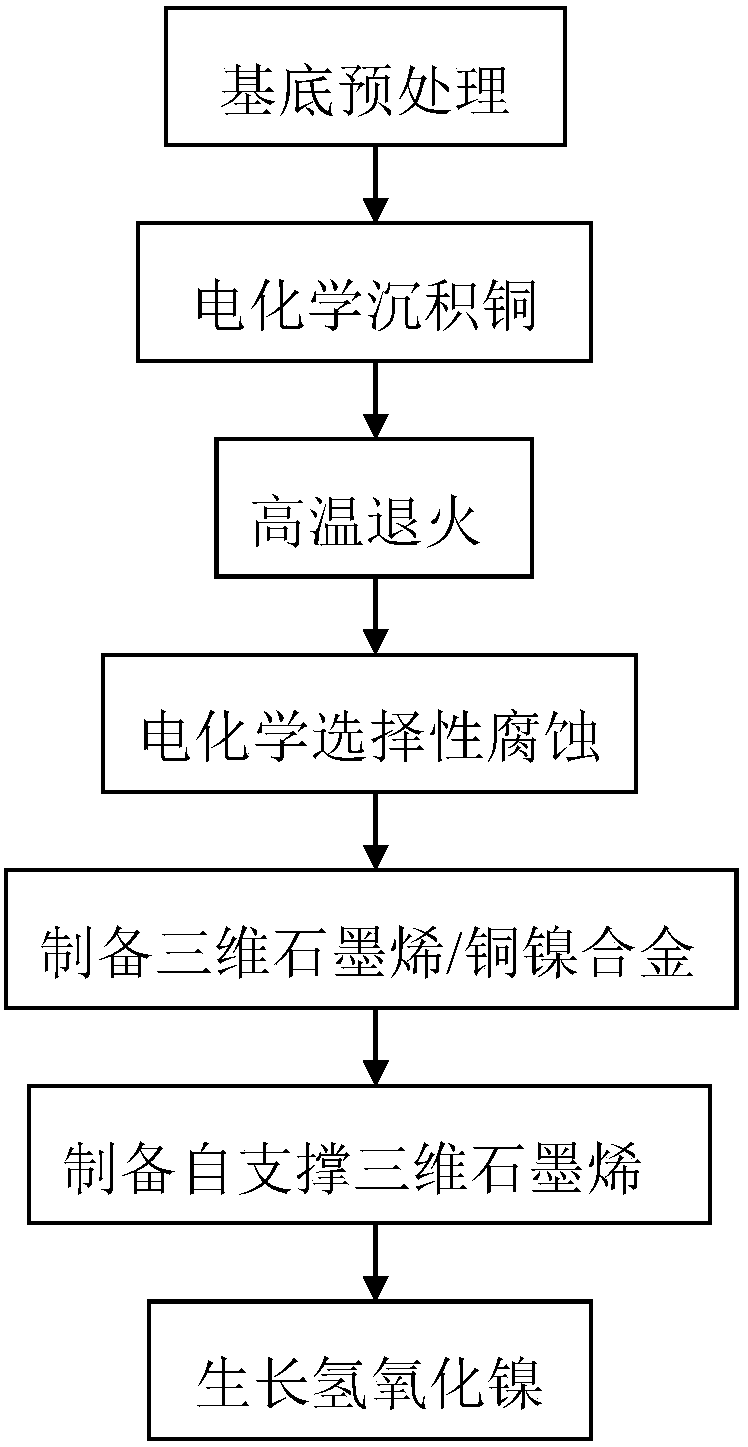

Preparation method of three-dimensional graphene/nickel hydroxide composite electrode material

A technology of nickel hydroxide and composite electrodes, applied in the field of physics, can solve the problems of low specific surface area, affecting the performance of material electrodes, etc., and achieve the effects of high specific surface area, high storage capacity, and high cycle charge and discharge times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Preparation of a three-dimensional graphene / nickel hydroxide composite electrode based on a nickel hydroxide growth time of 2 hours.

[0053] Step A: Substrate pretreatment.

[0054] Use a flattener to thin the foamed nickel sheet with a thickness of 1.6mm to obtain a foamed nickel sheet with a thickness of 0.25mm, then clean the foamed nickel sheet with ethanol, deionized water, and 5M HCl solution, and finally use deionized water to remove the foamed nickel sheet. After cleaning, the foamed nickel flakes after cleaning are obtained.

[0055] Step B: Electrochemical deposition of copper.

[0056] The electrochemical three-electrode method is adopted, in which the working electrode is a foamed nickel sheet, the reference electrode is Ag / AgCl, and the auxiliary electrode is Pt, and the cleaned foamed nickel sheet is placed in 2M CuSO 4 ·5H 2 O and 1M HBO 3 In the mixed solution, add the electrochemical deposition voltage of -1V, deposit for 100 minutes, an...

Embodiment 2

[0069] Example 2: Preparation of a three-dimensional graphene / nickel hydroxide composite electrode at a nickel hydroxide growth time of 8 hours.

[0070] Step 1: Substrate pretreatment.

[0071] Use a flattener to thin the foamed nickel sheet with a thickness of 1.6mm to obtain a foamed nickel sheet with a thickness of 0.25mm, then clean the foamed nickel sheet with ethanol, deionized water, and 5M HCl solution, and finally use deionized water to remove the foamed nickel sheet. After cleaning, the foamed nickel flakes after cleaning are obtained.

[0072] Step 2: Electrochemical deposition of copper.

[0073] The electrochemical three-electrode method is adopted, in which the working electrode is a foamed nickel sheet, the reference electrode is Ag / AgCl, and the auxiliary electrode is Pt, and the cleaned foamed nickel sheet is placed in 2M CuSO 4 ·5H 2 O and 1M HBO 3 In the mixed solution, add the electrochemical deposition voltage of -0.5V, deposit for 150 minutes, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com