Method for preparing fish oil microcapsules meeting organic food processing standards

A technology of organic food and microcapsules, which is applied in the forming of food, the function of food ingredients, and food ingredients, etc. It can solve the problems that microcapsules are difficult to use in organic food and the influence of organic integrity, so as to avoid high equipment cost and dense surface , Super stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

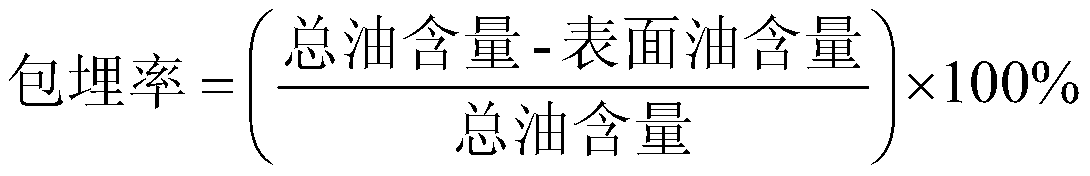

Method used

Image

Examples

Embodiment 1

[0027] 1) Take 100mL of sodium alginate solution with a mass concentration of 2.0%, add sesame meal with a mass concentration of 3.0%, and 50mL of fish oil to it, and mix the three together to form a stable emulsion through high-pressure homogenization;

[0028] The conditions for high-pressure homogenization are: pressure 80MPa, cycle number 4 times;

[0029] The sodium alginate solution, sesame meal, and fish oil all meet the requirements listed in the appendix of GB / T 19630.2;

[0030] 2) performing pressure spraying on the emulsion after high-pressure homogenization in step 1), and the atomized droplets fall into 3000 mL of calcium chloride solution with a mass concentration of 1.5%, forming fish oil microcapsules;

[0031] The conditions of the pressure spray are: the material flow rate is 20ml / min, the spray nitrogen pressure is 0.03MPa, and the spray granulation liquid surface distance is 30cm;

[0032] 3) After the fish oil microcapsules formed in step 2) are fully so...

Embodiment 2

[0036] 1) Take 100mL of sodium alginate solution with a mass concentration of 2.0%, add sesame meal with a mass concentration of 3.0%, and 50mL of fish oil to it, and mix the three together to form a stable emulsion through high-pressure homogenization;

[0037] The conditions for high-pressure homogenization are: pressure 70MPa, cycle times 4 times;

[0038] The sodium alginate solution, sesame meal, and fish oil all meet the requirements listed in the appendix of GB / T 19630.2;

[0039] 2) performing pressure spraying on the emulsion after high-pressure homogenization in step 1), and the atomized droplets fall into 2000 mL of calcium chloride solution with a mass concentration of 2.0%, forming fish oil microcapsules;

[0040] The conditions of the pressure spray are: the material flow rate is 30ml / min, the spray nitrogen pressure is 0.05MPa, and the spray granulation liquid surface distance is 40cm;

[0041] 3) After the fish oil microcapsules formed in step 2) are fully sol...

Embodiment 3

[0045] 1) Take 100mL of sodium alginate solution with a mass concentration of 2.5%, add sesame meal with a mass concentration of 4.0%, and 50mL of fish oil to it, and mix the three together to form a stable emulsion through high-pressure homogenization;

[0046] The conditions for high-pressure homogenization are: pressure 80MPa, cycle number 5 times;

[0047] The sodium alginate solution, sesame meal, and fish oil all meet the requirements listed in the appendix of GB / T 19630.2;

[0048] 2) performing pressure spraying on the emulsion after high-pressure homogenization in step 1), and the atomized droplets fall into 4500 mL of calcium chloride solution with a mass concentration of 2.0%, forming fish oil microcapsules;

[0049]The conditions of the pressure spray are: the material flow rate is 20ml / min, the spray nitrogen pressure is 0.05MPa, and the spray granulation liquid surface distance is 40cm;

[0050] 3) After the fish oil microcapsules formed in step 2) are fully sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com