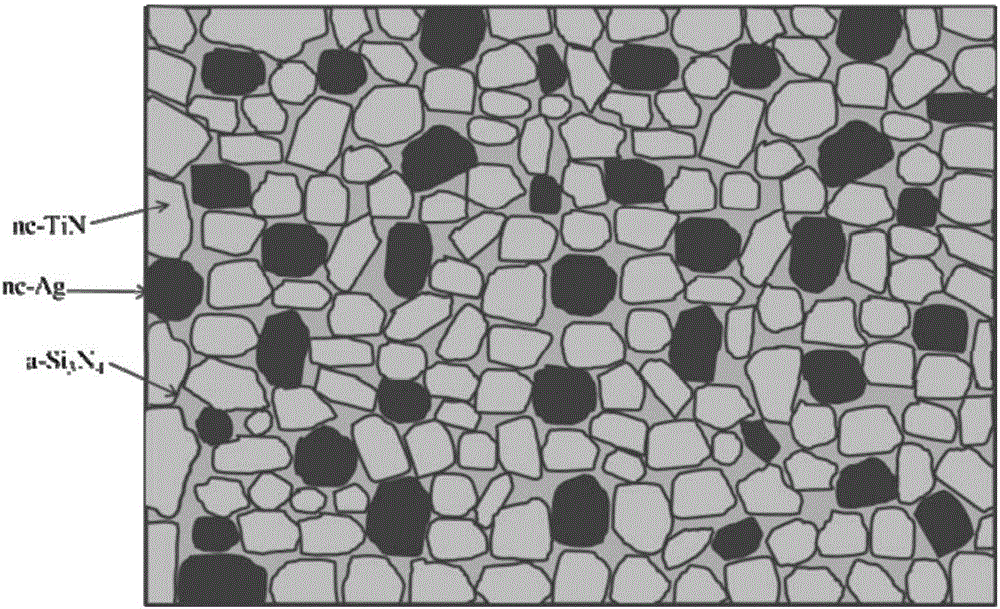

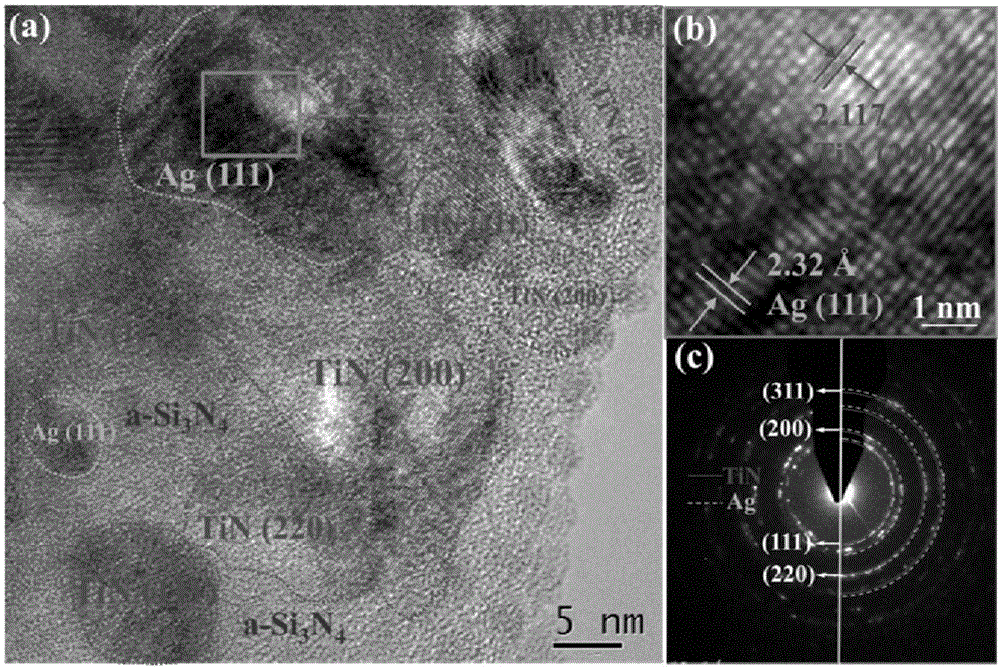

High-hardness antibacterial TiSiN/Ag nano composite functional coating and preparation method and application thereof

A composite coating and nanocomposite technology, applied in the field of materials, can solve the problems of poor wear resistance and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

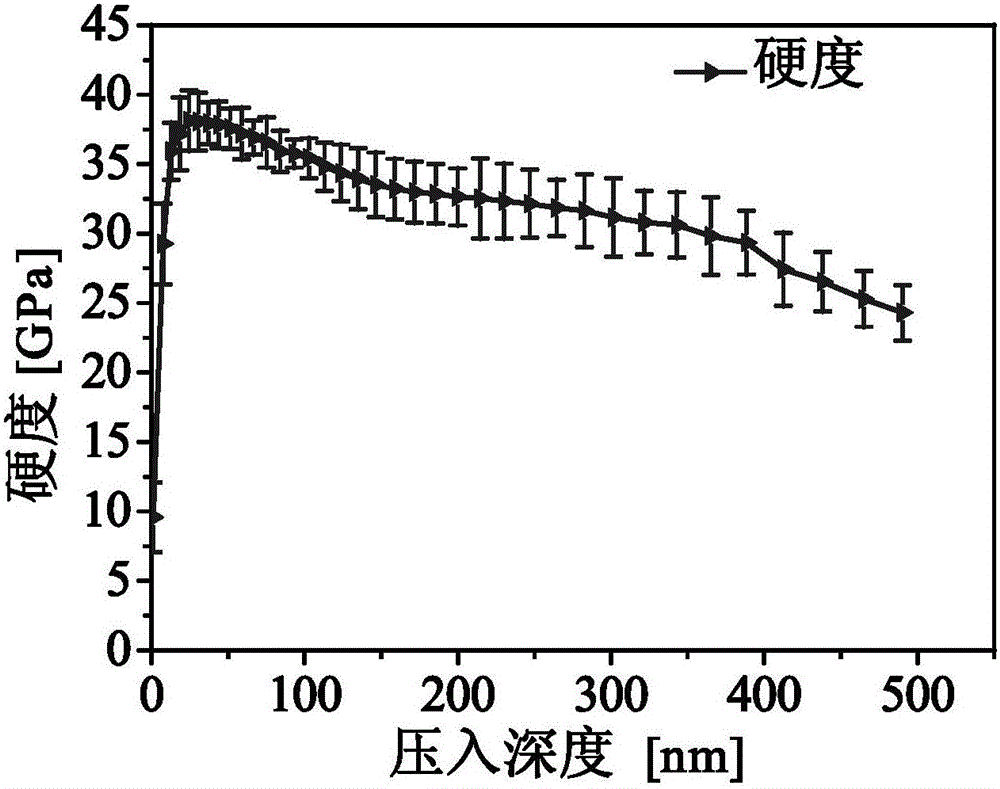

Examples

preparation example Construction

[0100] The present invention also provides a method for preparing the composite coating, comprising the steps of:

[0101] a) Under vacuum or inert atmosphere, preheating atmosphere, sputter cleaning is carried out on the substrate and target to be plated;

[0102] b) optionally under a high-purity nitrogen or nitrogen-argon mixed gas atmosphere, using a pure titanium target to deposit a transition layer on the surface of the substrate to be plated;

[0103] c) co-depositing a nanocomposite layer on the surface of the product obtained in the preceding step by using a titanium silicon target and an Ag target at the same time under a high-purity nitrogen or nitrogen-argon mixed gas atmosphere to obtain the composite coating;

[0104] d) optionally under an inert atmosphere, heat-treating the product obtained in the preceding step to obtain the composite coating.

[0105] In another preference, before step a), also include steps:

[0106] a-0) polishing the substrate to be plat...

Embodiment 1

[0144] Example 1 Coating 1

[0145] (1) Perform mechanical grinding and polishing on the titanium alloy test piece to be plated, then perform ultrasonic vibration cleaning in acetone reagent, wash the sample 3 times, and air-dry the sample after cleaning.

[0146] (2) Send the sample obtained in the preceding steps into a vacuum chamber, and the vacuum chamber is pre-evacuated, and the vacuum degree of the background is 1×10 -3 Pa, the vacuum chamber is heated during the pre-evacuation process, and the heating temperature is up to 400°C.

[0147] (3) When the background vacuum and heating temperature meet the requirements, the target is cleaned by sputtering for 2 minutes, and the sample to be plated is cleaned by ion sputtering and etching for 5 minutes.

[0148] (4) Multi-arc ion plating is used to first deposit a TiN transition layer on the sample to be plated, using a pure titanium target (target purity 99.9at.%), the reaction gas is high-purity nitrogen, and the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com