Production method of new functional vinegar drink by probiotic fermentation

A production method and probiotic technology are applied in the field of functional condiments and achieve the effects of good market application development prospects, stable production process and rich sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

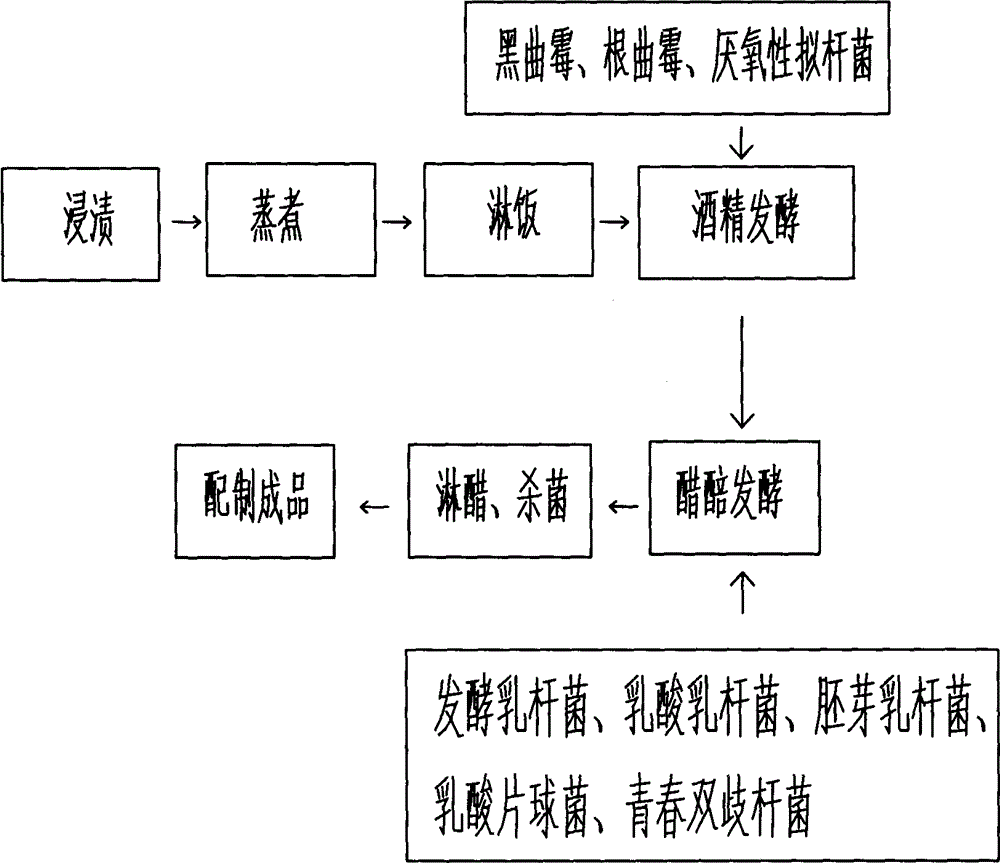

Method used

Image

Examples

Embodiment 1

[0034] Select 100kg of high-quality glutinous rice without mildew and with a starch content of about 70%, soak it in 200kg of clear water for 24 hours, fish it out with a bamboo bag, drain the remaining water, and the volume of the glutinous rice has expanded by about 36%.

[0035] After steaming, rinse with cold water and cool to 25°C, pour it into a vat and add 300 grams of wine medicine containing Rhizopus and yeast, including 200 grams of probiotics composed of Aspergillus niger, Aspergillus oryzae and anaerobic Bacteroides, mix Mix well, saccharify at 25°C for 72 hours, add 350kg of water, and keep warm at 28°C for 48 hours to obtain mature fermented grains.

[0036] ①Inoculation culture stage (pre-fermentation): Add a probiotic mixture composed of Lactobacillus fermentum, Lactobacillus lactis, Lactobacillus plantarum, Pediococcus lactis, and Bifidobacterium adolescentis, then insert acetic acid bacteria, gradually cultivate and expand, after In 1 day, all the raw materia...

Embodiment 2

[0043] Select 100kg of high-quality glutinous rice without mildew and with a starch content of about 75%, soak it in 400kg of clear water for 30 hours, fish it out with a bamboo bag, drain the remaining water, and the volume of the glutinous rice has expanded by about 40%.

[0044] After steaming, rinse with cold water and cool to 30°C, pour it into a vat and add 300 grams of wine medicine containing Rhizopus and yeast, including 300 grams of probiotics composed of Aspergillus niger, Aspergillus oryzae and anaerobic Bacteroides, mix Mix well, saccharify at 26°C for 72 hours, add 350kg of water, and keep warm at 28°C for 48 hours to obtain mature fermented grains.

[0045]①Inoculation culture stage (pre-fermentation): Add a probiotic mixture composed of Lactobacillus fermentum, Lactobacillus lactis, Lactobacillus plantarum, Pediococcus lactis, and Bifidobacterium adolescentis, then insert acetic acid bacteria, gradually cultivate and expand, after In 1 day, all raw materials co...

Embodiment 3

[0050] Select 100kg of high-quality glutinous rice without mildew and with a starch content of about 73%, soak it in 300kg of clear water for 27 hours, fish it out with a bamboo sieve, drain the remaining water, and the volume of the glutinous rice has expanded by about 38%.

[0051] After steaming, rinse with cold water and cool to 28°C, pour it into a vat and add 250 grams of wine medicine containing Rhizopus and yeast, including 250 grams of probiotics composed of Aspergillus niger, Aspergillus oryzae and anaerobic Bacteroides, mix Mix well, saccharify at 26°C for 72 hours, add 350kg of water, and keep warm at 28°C for 48 hours to obtain mature fermented grains.

[0052] ①Inoculation culture stage (pre-fermentation): Add a probiotic mixture composed of Lactobacillus fermentum, Lactobacillus lactis, Lactobacillus plantarum, Pediococcus lactis, and Bifidobacterium adolescentis, then insert acetic acid bacteria, gradually cultivate and expand, after In 1 day, all raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com