A kind of preparation method of cold water dispersible beta-carotene microcapsules

A carotene dispersion technology, applied in the field of preparation of β-carotene microcapsules, can solve the problems of large particle size, high price, and poor cold water dispersibility of microcapsules, and achieve high bioavailability, wide and convenient use, and good dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

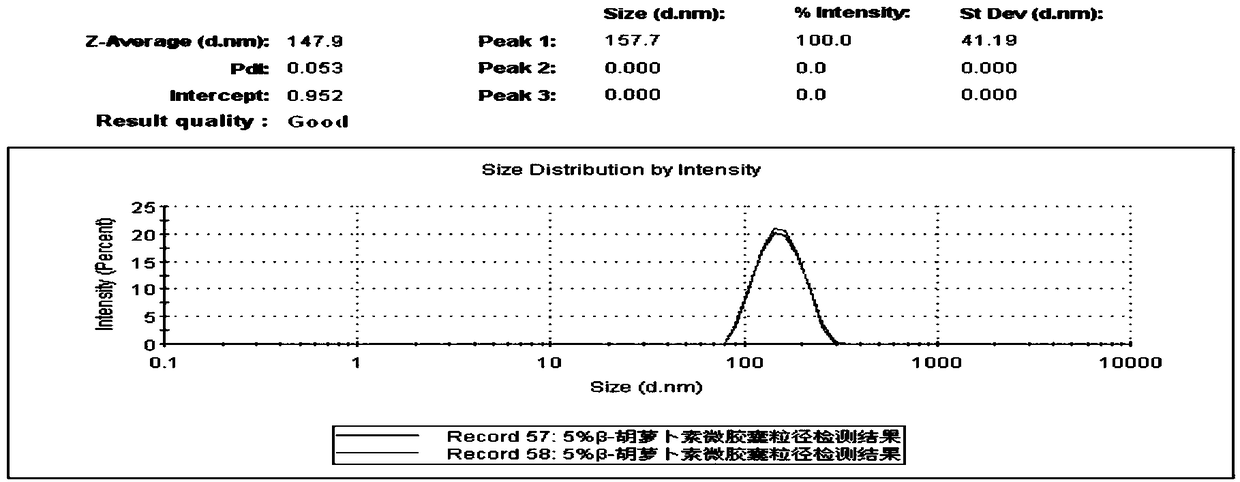

Image

Examples

preparation example Construction

[0026] A preparation method of cold water dispersible β-carotene microcapsules, comprising the following steps:

[0027] 1) dispersing β-carotene, limonene and antioxidants in methyl oleate to form a suspension; wherein, limonene can increase the trans content of β-carotene microcapsules;

[0028] 2) Place the suspension obtained in step 1) in a ball mill for grinding, so that the mass percentage of particles with a particle diameter less than 10 μm in the suspension accounts for more than 90% of the total particles; the grinding medium of the ball mill is 0.8 to 1.0 mm in diameter zirconia beads;

[0029] 3) Heat the suspension ground in step 2) to 70°C, then pass through the spiral heat pipe at a temperature of 180-220°C at a rate of 1.5-1.8kg / h, and the time for passing through the spiral heat pipe is 1-3s , to obtain molecular dispersion solution;

[0030] The spiral heat pipe is beneficial to increase the contact area between the suspension and the heat pipe, quickly co...

Embodiment 1

[0035] This embodiment discloses a preparation method of cold water dispersible β-carotene microcapsules, comprising the following steps:

[0036] 1) Disperse 13g of β-carotene, 10g of limonene and 0.5g of tocopherol in 30g of methyl oleate to form a suspension;

[0037] 2) Place the suspension obtained in step 1) in a ball mill for grinding, so that the mass percentage of particles with a particle diameter less than 10 μm in the suspension accounts for more than 90% of the total particles; the grinding medium of the ball mill is 0.8 to 1.0 mm in diameter zirconia beads;

[0038] 3) Heat the suspension ground in step 2) to 70°C, then pass through the spiral heat pipe with a temperature of 210°C at a rate of 1.6kg / h, and the time for passing through the spiral heat pipe is 1.5s to complete the heat exchange, Obtain molecular dispersion solution;

[0039] 4) Pass the molecular dispersion solution obtained in step 3) into the water-soluble protective colloid prepared by 130g ca...

Embodiment 2

[0043] 1) Disperse 15g of β-carotene, 12g of limonene and 0.8g of tocopherol in 30g of methyl oleate to form a suspension;

[0044] 2) Place the suspension obtained in step 1) in a ball mill for grinding, so that the mass percentage of particles with a particle diameter less than 10 μm in the suspension accounts for more than 90% of the total particles; the grinding medium of the ball mill is 0.8 to 1.0 mm in diameter zirconia beads;

[0045] 3) Heat the suspension ground in step 2) to 70°C, then pass through a spiral heat pipe with a temperature of 200°C at a rate of 1.5kg / h, and the time for passing through the spiral heat pipe is 1s to complete the heat exchange, and obtain Molecular dispersion solution;

[0046] 4) Pass the molecular dispersion solution obtained in step 3) into the water-soluble protective colloid prepared by 145g calcium lignosulfonate and 650g water, and use a high-pressure homogenizer (APV 2000) to homogenize under a pressure of 1000bar to form Disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com