Medical adhesive and preparation method thereof

An adhesive and gelatin technology, used in pharmaceutical formulations, applications, medical science and other directions, can solve the problems of gelled albumin dissolution, insufficient biosafety, virus infection, etc., and achieve strong adhesion and excellent biosafety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

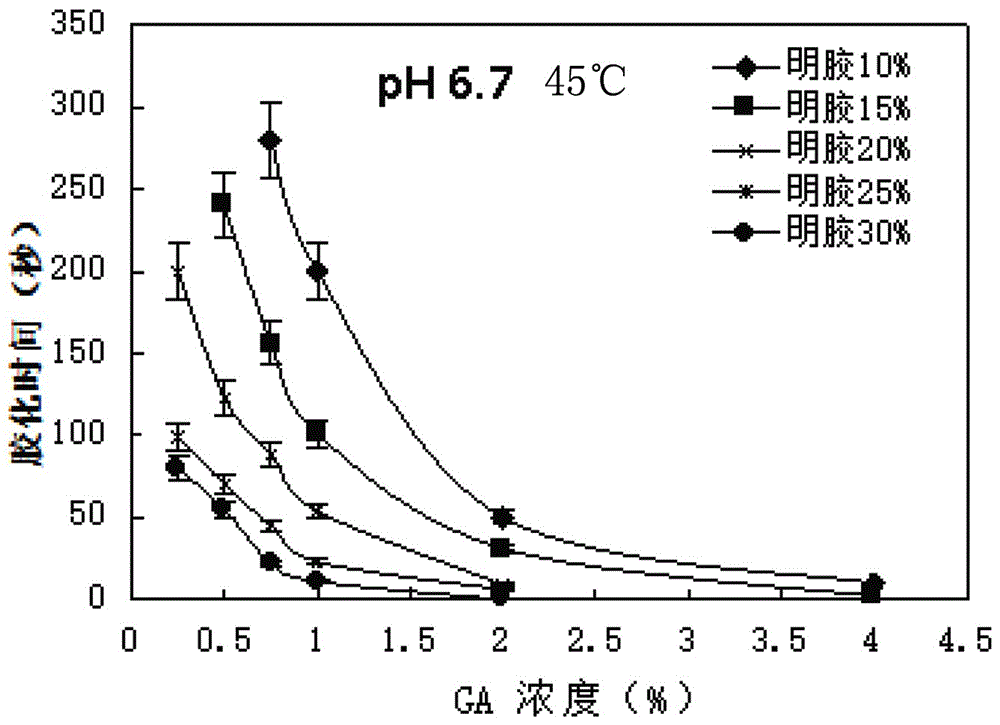

[0037] (Optimization of gelation time) Gelatin powder was added to phosphate buffer saline PBS (-) to prepare 10%, 15%, 20%, 25%, and 30% solutions. Glutaraldehyde was added with distilled water to prepare 0.25%, 0.5%, 0.75%, 1%, 2%, and 4% solutions. Gelatin aqueous solution 10mL, glutaraldehyde aqueous solution 2mL, each kept at 45°C for 30 minutes, then mixed the two liquids, put the mixed liquid into a rotor with a diameter of 2 cm, and started to rotate at 80 rpm. With the increase of the viscosity of the solution, the rotor rotated slowly, and then stopped to measure Gelation time, data obtained on average of 4 times, at 45°C, the experimental results of the relationship between glutaraldehyde (GA) solution concentration and gelation time are as follows figure 1 . From figure 1 It can be seen that under certain temperature and pH conditions, the lower the concentration of gelatin solution, the longer the gelation time. The lower the concentration of glutaraldehyde, th...

Embodiment 2

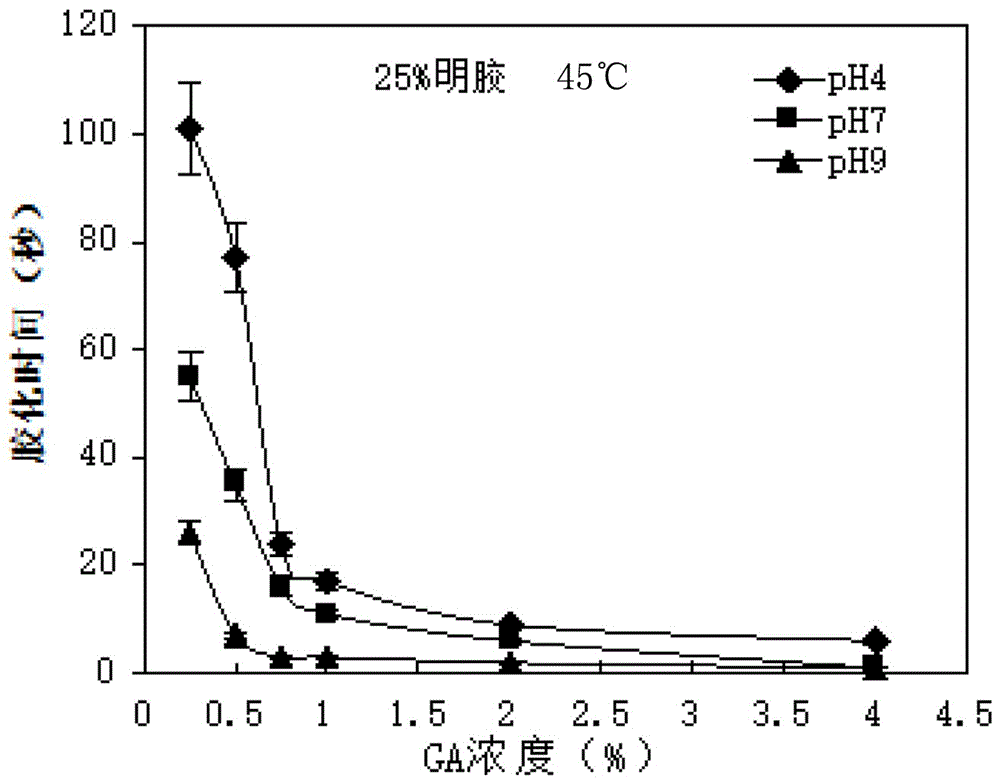

[0039] (Effect of pH on gelation) Gelatin powder was adjusted to 25% solution by adding phosphate buffer saline PBS (-), and pH of gelatin solution was adjusted to pH 4.0, 7.0, 9.0. In addition, distilled water was added to glutaraldehyde to prepare 0.25%, 0.5%, 0.75%, 1%, 2%, and 4% solutions. Add 10 mL of aqueous gelatin solution to 2 mL of glutaraldehyde aqueous solution, heat each at 45°C for 30 minutes, and mix the two liquids. Put the mixed solution into a rotor with a diameter of 2 cm, and adjust the rotor to rotate at 80 rpm. As the viscosity of the solution increases, the rotor rotates slower, and then stops to measure the gelation time. 4 average data are obtained, the relationship between the pH of the gelatin aqueous solution and the gelation time is as follows figure 2 Show (GA is glutaraldehyde). From figure 2 It can be seen that at a certain temperature and gelatin concentration, high pH environmental conditions promote gelation (gelation time shortens).

Embodiment 3

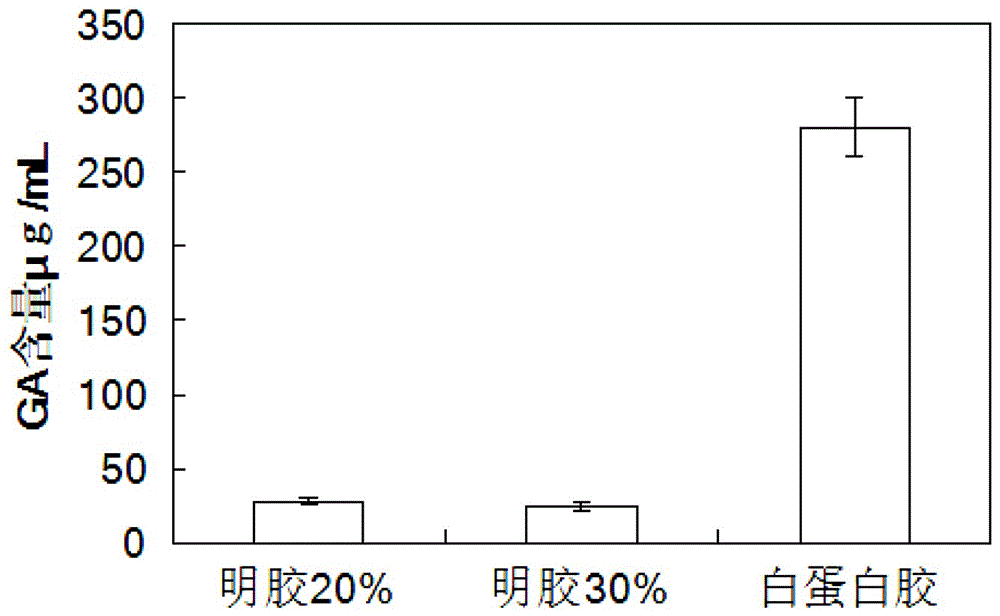

[0041] (Amount of glutaraldehyde extracted from the gel) Add phosphate buffered saline (PBS) (-) to gelatin powder to prepare 5.0 mL each of 20% and 30% solutions. In addition, add glutaraldehyde to distilled water to prepare 1 mL of 1.0% solution, 45°C After incubation, the two liquids are mixed to make a gel. Compared with commercially available albumin glue (Cryolife International Corp), according to its composition and use, distilled water was added to make 45% albumin solution, and 10% glutaraldehyde aqueous solution was prepared and mixed to make albumin glue. Soak in 5 times the weight of phosphate buffer at 37°C for 1 minute, then measure the amount of glutaraldehyde extracted from the phosphate buffer (hydroxylamine hydrochloride acid-base titration method), obtain the data on average for 4 times, and the results are as follows image 3 , the amount of glutaraldehyde obtained by the dissolution of this gel is much less than that extracted from the albumin gel (GA is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com