A kind of sodium citrate magnetic nano particle forward osmosis drawing solution and preparation method thereof

A technology of magnetic nanoparticles and sodium citrate, which is applied in the environmental field, can solve few problems and achieve the effects of convenient operation, good economic and social benefits, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation of ferroferromagnetic nanoparticles

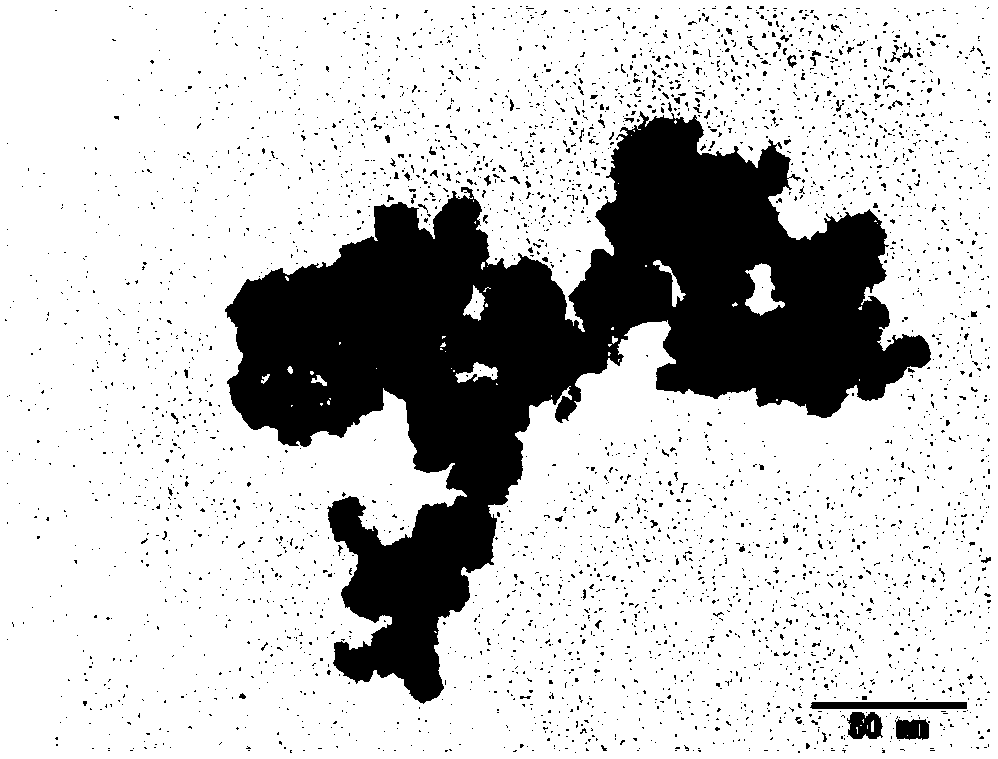

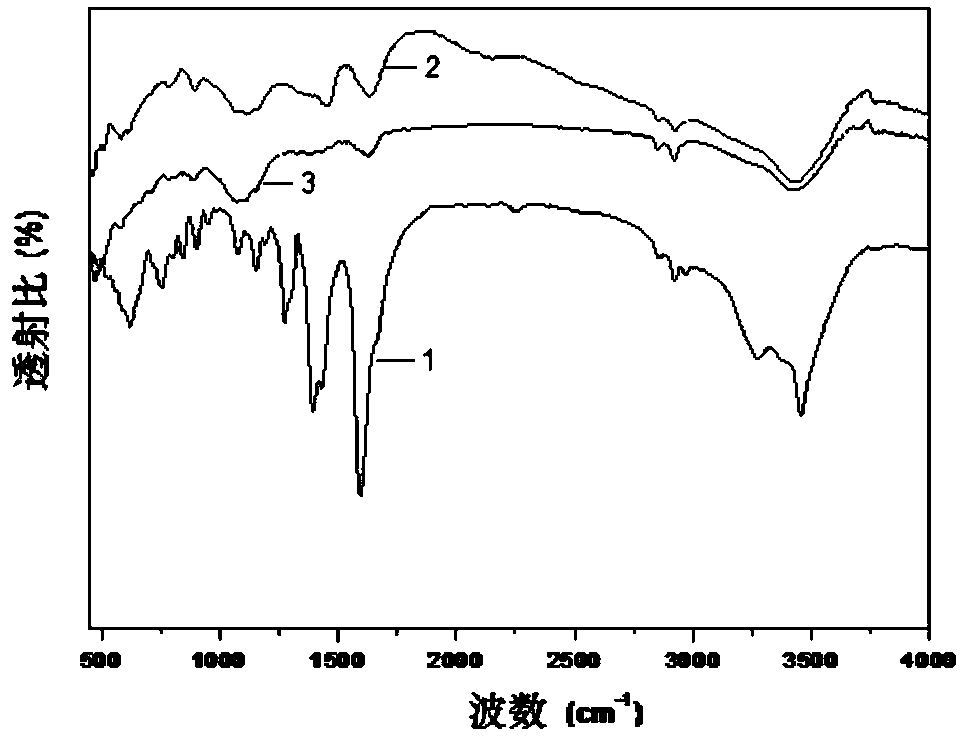

[0025] Ferric chloride (FeCl 3 ·6H 2 O) and ferrous chloride (FeCl 2 4H 2 O) With the ratio of substances of 1:2, after being dissolved in distilled water of the same volume respectively, dropwise in the sodium hydroxide solution with a dropping funnel, under the protection of nitrogen, set the stirring speed as 320rpm, and continuously stir for 30min until completely mixed; then heated to 80°C, continued to stir for 3 hours, and naturally cooled to room temperature to obtain a black gel-like precipitate; finally, the black gel-like precipitate was centrifuged at a speed of 5000-7000rpm for 10- After 15 minutes, the top liquid was separated from the separation tube, and the obtained precipitate was washed to neutrality with ultrapure water, and dried at -18°C for 16 hours to obtain ferroferric oxide magnetic nanoparticles. The TEM image is as follows figure 1 As shown, the infrared analysis diagram is s...

Embodiment 2

[0027] Example 2: Preparation of Sodium Citrate Magnetic Nanoparticles Forward Osmosis Drawing Solution

[0028] Sodium citrate solution was added to the ferroferric oxide magnetic nanoparticles prepared, heated to 95° C. and vigorously stirred for 1 hour to obtain a black gel-like suspension; Centrifuge for 10-15min under the same conditions, remove the supernatant, wash the obtained precipitate with ultrapure water and centrifuge again, repeat 2-3 times; finally dry the washed precipitate at -20°C for 14 hours to obtain lemon Sodium Oxide Magnetic Nanoparticles. The obtained sodium citrate magnetic nanoparticles were dispersed in distilled water, and then sonicated for 20-30 min to obtain the sodium citrate magnetic nanoparticles forward osmosis draw solution.

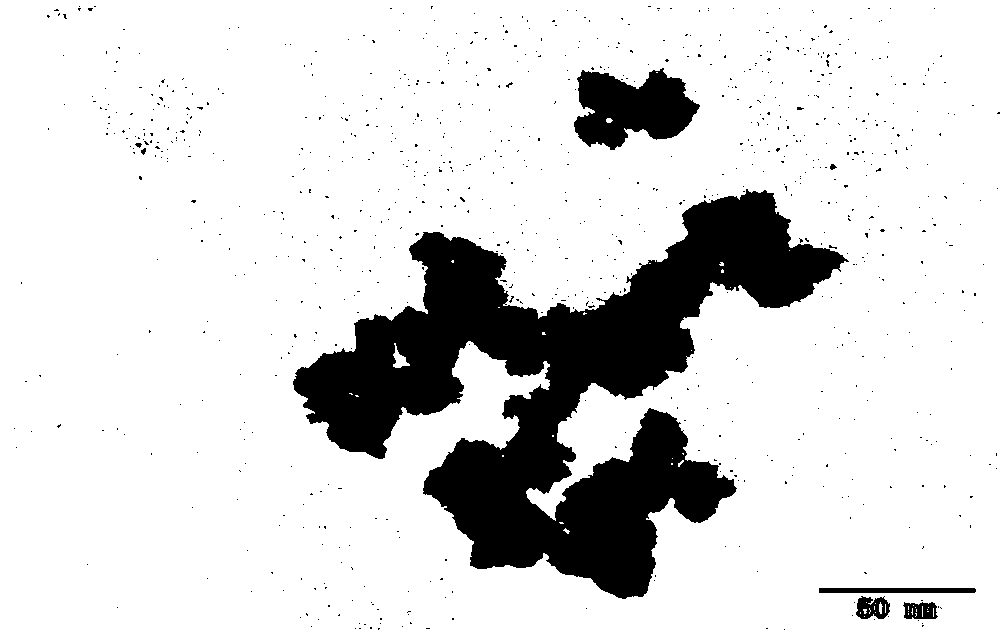

[0029] The TEM figure of the obtained sodium citrate magnetic nanoparticles is as follows figure 2 shown by figure 2 It can be seen that the agglomeration phenomenon of ferroferric oxide magnetic nanoparticles m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com