Device and method for parallel mask-less scanning micro-nano processing based on atmospheric pressure plasma jet tube

A micro-nano processing, plasma technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problem that it is not suitable for scanning processing, and the processing resolution cannot be further improved to submicron and nanometer quantities. high-efficiency maskless etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The preferred embodiment of the parallel maskless scanning micro-nano processing device based on the atmospheric pressure plasma nozzle of the present invention is:

[0020] It includes an atmospheric pressure plasma nozzle and a micro-nano nozzle array integrated at the lower end of the nozzle, and the lower part of the nozzle array is provided with a three-dimensional precision mobile platform;

[0021] The atmospheric pressure plasma nozzle includes an anode metal tube, a quartz tube, and an insulating tube arranged sequentially from the inside to the outside, the lower end of the insulating tube is provided with a cathode metal ring, and a metal ring is connected between the anode metal tube and the cathode metal ring. Voltage excitation device and current limiting resistor;

[0022] The voltage excitation device is a DC pulse voltage generating device or a high frequency AC excitation device or a radio frequency excitation device or a microwave excitation device; ...

specific Embodiment

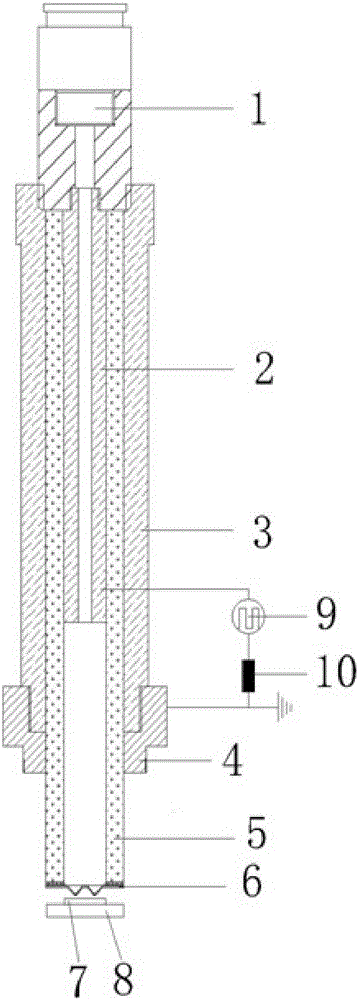

[0051] see figure 1 , the present embodiment is an atmospheric pressure plasma nozzle micro-nano jet device for parallel scanning plasma processing, which is composed of an atmospheric pressure plasma nozzle, a needle tip array with micro-nano nozzles and a three-dimensional mobile platform. The atmospheric pressure plasma nozzle is composed of an air inlet 1, an anode metal tube 2, an insulating tube 3, a cathode metal ring 4 and a quartz tube 5. The material of the insulating tube 3 can be an insulating material such as polytetrafluoroethylene, and the electrodes 2 and 4 The material can be a metal that is not easily oxidized, such as copper.

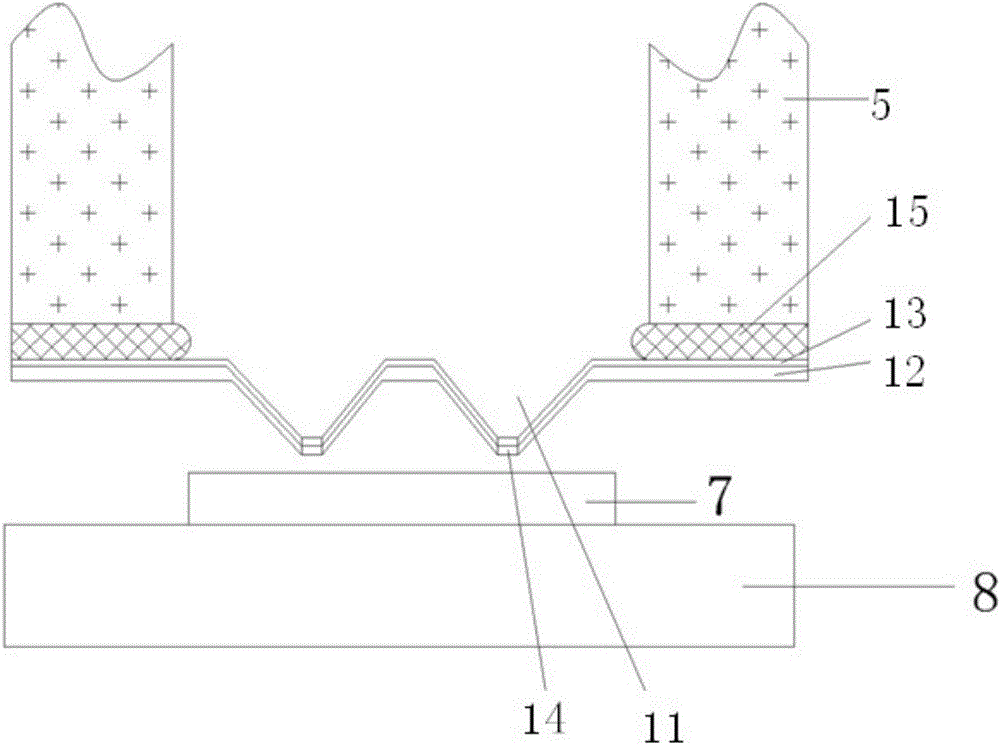

[0052] Nanonozzle tip arrays such as figure 2 As shown, it is a device with a metal layer / oxide layer two-layer structure. The substrate of the device is a single crystal silicon wafer, and an inverted pyramid-shaped cavity 11 is obtained by anisotropic etching with KOH etching solution. The surface is oxidized by wet oxygen to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com