Method for preparing high-additional-value chemicals by different pH acid-alkali pretreatment of biomass and one-step cracking

A high value-added, biomass technology, applied in the preparation of sugar derivatives, chemical instruments and methods, preparation of carboxylate, etc., can solve the problem of unreported research on the distribution of thermal cracking products, and achieve simple operation, energy saving, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

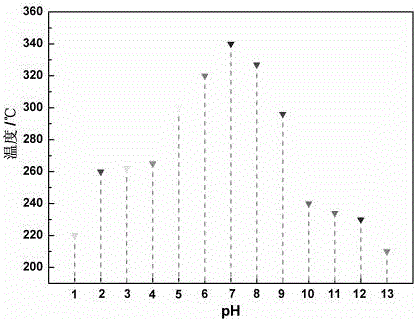

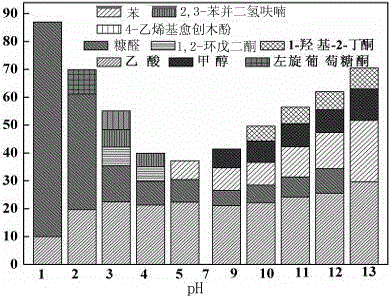

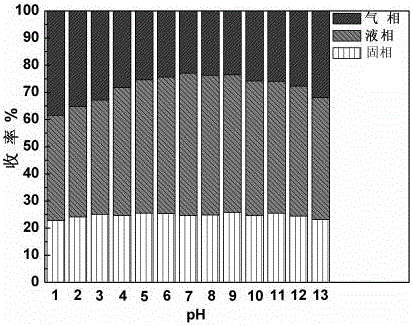

[0037] Configured with sulfuric acid pHA pretreatment solution of 1 was used in this experiment, and the corncob powder was treated with the pretreatment solution in a continuous stirred tank reactor, that is, 3 g of corncobs and 30 ml of pretreatment solution were added to the reactor, and then in 30 min Internally heated to 373K, kept at 600rpm for 3 hours, the rotary evaporator was used to evaporate the water in the pretreatment liquid, the remaining corncobs were transferred to a 20cm glass dish, vacuum dried at 333K for 48h to obtain the product, and the above corncobs were weighed and 0.6 g HZSM-5 molecular sieve, after fully stirring evenly, pack on the quartz sand in the middle part of the reaction tube (diameter = 25 mm, length = 400 mm), feed 40ml / min of nitrogen for air tightness inspection, after passing, Continue to ventilate for 3 minutes to remove the internal air. Then, raise the temperature at a rate of 50°C / min. When the temperature rises to 500°C, stay for 1...

Embodiment 2

[0039] Configured with sulfuric acid pH The pretreatment liquid of 2 was used in this experiment, and the corncob powder was treated with the pretreatment liquid in the continuous stirred tank reactor, that is, 3g of corncobs and 30ml of the pretreatment liquid were added to the reactor, and then in 30min Internally heated to 373K, kept at 600rpm for 3 hours, the rotary evaporator was used to evaporate the water in the pretreatment liquid, the remaining corncobs were transferred to a 20cm glass dish, vacuum dried at 333K for 48h to obtain the product, and the above corncobs were weighed and 0.6 g HZSM-5 molecular sieve, after fully stirring evenly, pack on the quartz sand in the middle part of the reaction tube (diameter = 25 mm, length = 400 mm), feed 40ml / min of nitrogen for air tightness inspection, after passing, Continue to ventilate for 3 minutes to remove the internal air. Then, raise the temperature at a rate of 50°C / min. When the temperature rises to 500°C, stay for 1...

Embodiment 3

[0041] Configured with sulfuric acid pH The pretreatment solution of 3 was used in this experiment, the corn cob powder was treated with the pretreatment solution in the continuous stirred tank reactor, that is, 3g of corn cob and 30ml of the pretreatment solution were added to the reactor, and then the 30min Internally heated to 373K, kept at 600rpm for 3 hours, the rotary evaporator was used to evaporate the water in the pretreatment liquid, the remaining corncobs were transferred to a 20cm glass dish, vacuum dried at 333K for 48h to obtain the product, and the above corncobs were weighed and 0.6 g HZSM-5 molecular sieve, after fully stirring evenly, pack on the quartz sand in the middle part of the reaction tube (diameter = 25 mm, length = 400 mm), feed 40ml / min of nitrogen for air tightness inspection, after passing, Continue to ventilate for 3 minutes to remove the internal air. Then, raise the temperature at a rate of 50°C / min. When the temperature rises to 500°C, stay f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com