Scrubbing resistance two-component acetic acrylic polymer modified cement-base waterproof coating and preparation method thereof

A waterproof coating, two-component technology, applied in the direction of coating, etc., can solve the problems of poor scrub resistance, achieve the effect of improving mechanical properties, improving wear resistance, and improving scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

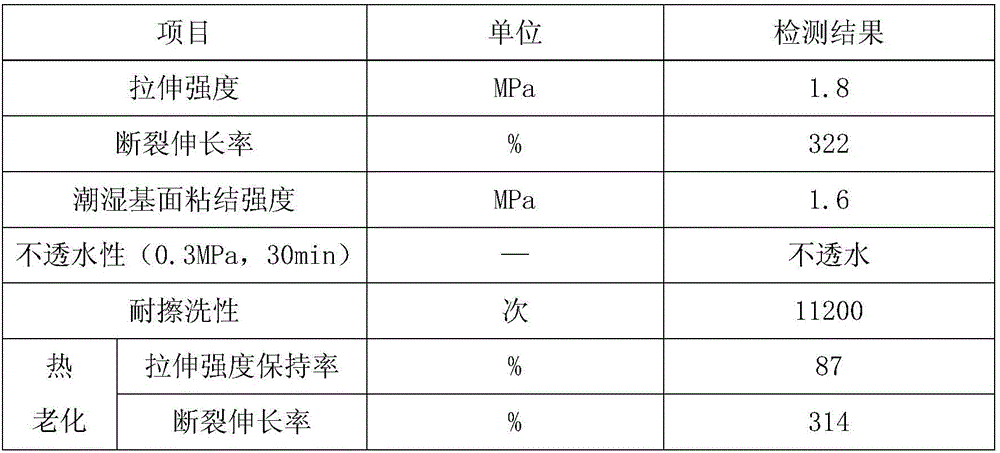

Image

Examples

Embodiment Construction

[0021] A scrub-resistant two-component vinegar-propylene polymer cement-based waterproof coating, which is composed of liquid material A and powder B in a mass ratio of 1.5:1.

[0022] Described liquid material A is made from the raw material of following weight (kg): solid content is 50% vinegar acrylic emulsion 82, solid content is the nano-alumina sol 28 of 25%, lauryl alcohol ester 8, vinyltrimethoxy Silane 3, polyethyleneimine 10, sodium lauryl polyoxyethylene ether sulfate 2.5, glycidyl methacrylate 4, sodium alginate 7, sodium starch octenyl succinate 5, N-dodecyl double quaternary Ammonium salt 2.5, water 80;

[0023] The powder B is made of the following raw materials in parts by weight: fly ash portland cement 42, calcium silicate slag 23, asbestos tailings 17, activated alumina 9, silicon micropowder 18, oil shale ash 24, Magnesite slag 18, hemp knife ash 12, whisker silicon 8, heavy calcium powder 12, nano attapulgite 13, anorthite 20.

[0024] A preparation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com