Humidity controlling acrylic emulsion and preparation method thereof

The technology of acrylic emulsion and acrylic acid alkyl ester is applied to the field of interior wall styrene-acrylic moisture-regulating emulsion and its preparation, which can solve the problems of complicated process and high cost, and achieve the effects of increasing molecular weight, improving adhesion and good moisture absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

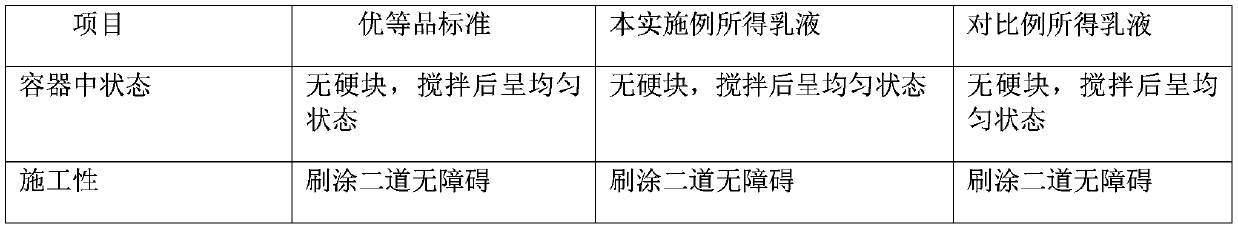

Embodiment 1

[0037] Embodiment 1: A kind of humidity control acrylic emulsion and its preparation method

[0038] A humidity-adjusting acrylic emulsion, prepared from the following raw materials in parts by weight: 91 parts of distilled water, 2 parts of anionic emulsifier, 2 parts of nonionic emulsifier, 40 parts of styrene, 50 parts of alkyl acrylate, unsaturated hydrocarbon acid 2 parts, 1 part of acrylamide, 2 parts of hydroxyl-containing acrylate monomer, 30 parts of humectant, 1 part of crosslinking monomer, 0.5 part of initiator, 0.3 part of oxidizing agent, and 0.3 part of reducing agent;

[0039] The anionic emulsifier is sodium dodecylsulfonate; the nonionic emulsifier is fatty alcohol polyoxyethylene ether; the alkyl acrylate is butyl acrylate; the unsaturated hydrocarbon acid is acrylic acid; The hydroxyl-containing acrylate monomer is hydroxyethyl acrylate; the humectant is urea; the cross-linking monomer is glycidyl methacrylate; the initiator is ammonium persulfate; Hydroge...

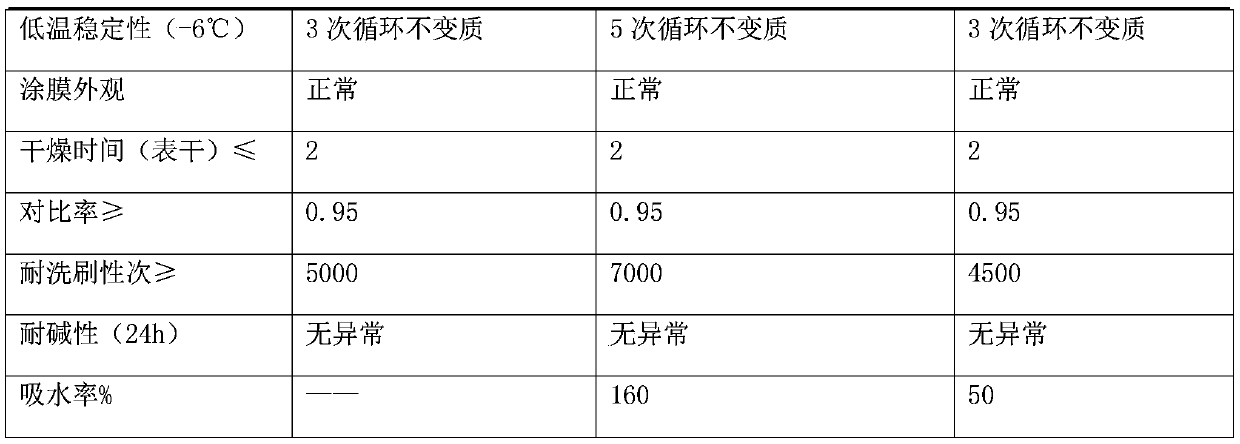

Embodiment 2

[0056] Embodiment 2: A kind of humidity control acrylic emulsion and preparation method thereof

[0057] A humidity-adjusting acrylic emulsion, prepared from the following raw materials in parts by weight: 122 parts of distilled water, 2 parts of anionic emulsifier, 2 parts of nonionic emulsifier, 70 parts of styrene, 80 parts of alkyl acrylate, unsaturated hydrocarbon acid 3 parts, 3 parts of acrylamide, 3 parts of hydroxyl-containing acrylate monomer, 50 parts of humectant, 2 parts of crosslinking monomer, 0.8 part of initiator, 0.5 part of oxidizing agent, and 0.5 part of reducing agent;

[0058] The anionic emulsifier is sodium dodecylsulfonate; the nonionic emulsifier is nonylphenol polyoxyethylene ether; the alkyl acrylate is isooctyl acrylate; the unsaturated hydrocarbon acid is methyl Acrylic acid; the hydroxyl-containing acrylate monomer is hydroxyethyl methacrylate; the moisturizing agent is hydroxyethyl urea; the crosslinking monomer is vinyl triethoxysilane; the in...

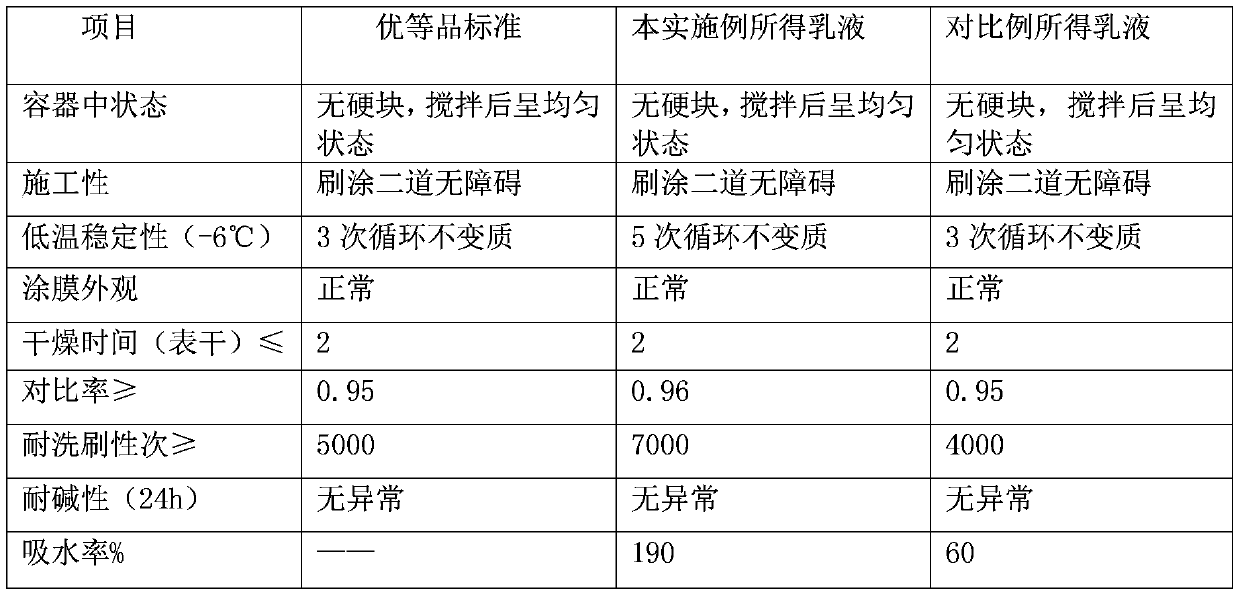

Embodiment 3

[0074] Embodiment 3: A kind of humidity control acrylic emulsion and preparation method thereof

[0075] A humidity-adjusting acrylic emulsion, prepared from the following raw materials in parts by weight: 71 parts of distilled water, 1 part of anionic emulsifier, 1 part of nonionic emulsifier, 30 parts of styrene, 40 parts of alkyl acrylate, unsaturated hydrocarbon acid 1 part, 1 part of acrylamide, 1 part of hydroxy-containing acrylate monomer, 10 parts of humectant, 0.1 part of crosslinking monomer, 0.5 part of initiator, 0.1 part of oxidizing agent, 0.1 part of reducing agent;

[0076] The anionic emulsifier is sodium dodecylsulfonate; the nonionic emulsifier is alkylphenol polyoxyethylene ether; the alkyl acrylate is ethyl acrylate; the unsaturated hydrocarbon acid is itaconic acid The hydroxyl-containing acrylate monomer is hydroxypropyl acrylate; the moisturizing agent is urea; the crosslinking monomer is vinyltrimethoxysilane; the initiator is sodium persulfate; the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com