Wear-resistant anti-freezing coating

An anti-freeze coating and coating technology, applied in the coating field, can solve the problems of poor adaptability, narrow application range, poor low temperature resistance, etc., and achieve the effects of reducing dosage, low production cost and improving painting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

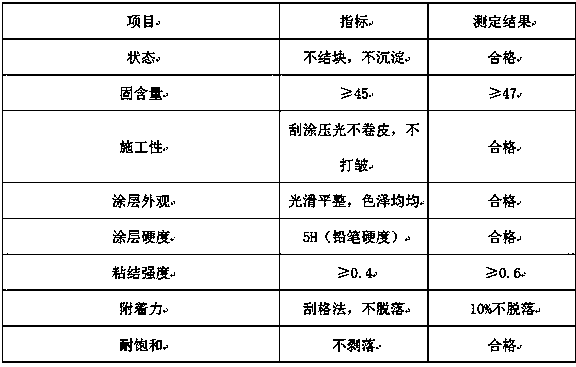

Examples

Embodiment 1

[0018] A wear-resistant antifreeze coating, made of the following raw materials in parts by weight: 50 parts of core-shell acrylic emulsion, 30 parts of modified starch, 40 parts of polyvinyl alcohol emulsion, 20 parts of titanium dioxide, 0.2 parts of ammonium persulfate, carbonic acid 0.2 parts of sodium hydrogen, 5 parts of lithopone, 0.3 parts of sodium hexametaphosphate, 0.3 parts of sodium fluoride, 0.4 parts of tributyl phosphate, 0.5 parts of dispersant, 0.08 parts of wetting agent, 0.2 parts of defoaming agent, 75 parts of water 15 parts of light calcium, 15 parts of talcum powder, 20 parts of precipitated barium sulfate, and 5 parts of bentonite.

[0019] A wear-resistant and antifreeze coating, the preparation method of which comprises the following steps: (1) After adding the core-shell acrylic emulsion into ammonium persulfate for reaction, adding sodium bicarbonate and 20 parts of water. Under the protection of nitrogen, after stirring and reacting at 40°C for 30...

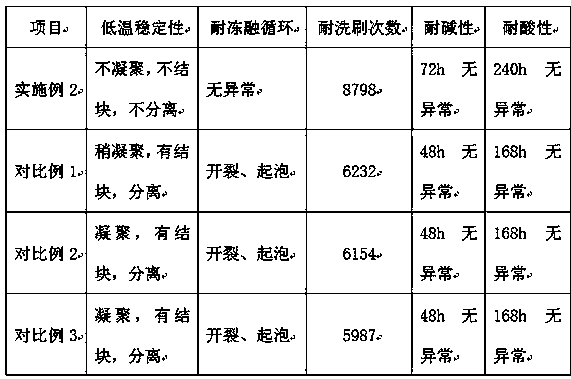

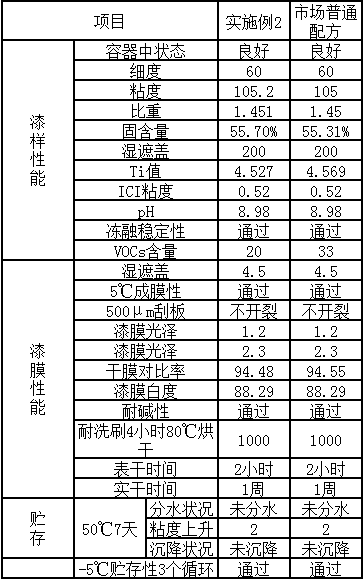

Embodiment 2

[0027] A wear-resistant antifreeze coating, made of the following raw materials in parts by weight: 40 parts of core-shell acrylic emulsion, 20 parts of modified starch, 40 parts of polyvinyl alcohol emulsion, 120 parts of titanium dioxide, 0.4 parts of ammonium persulfate, carbonic acid 0.2 parts of sodium hydrogen, 7 parts of lithopone, 0.5 parts of sodium hexametaphosphate, 0.45 parts of sodium fluoride, 0.5 parts of tributyl phosphate, 1 part of dispersant, 0.08 parts of wetting agent, 0.2 parts of defoaming agent, 75 parts of water 15 parts of light calcium, 15 parts of talcum powder, 20 parts of precipitated barium sulfate, and 5 parts of bentonite.

[0028] A wear-resistant and antifreeze coating, the preparation method of which comprises the following steps: (1) After adding the core-shell acrylic emulsion into ammonium persulfate for reaction, adding sodium bicarbonate and 20 parts of water. Under the protection of nitrogen, after stirring and reacting at 60°C for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com