Heat-peelable pressure-sensitive adhesive sheet

A thermal peeling, adhesive sheet technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc. The effect of excellent force and excellent peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

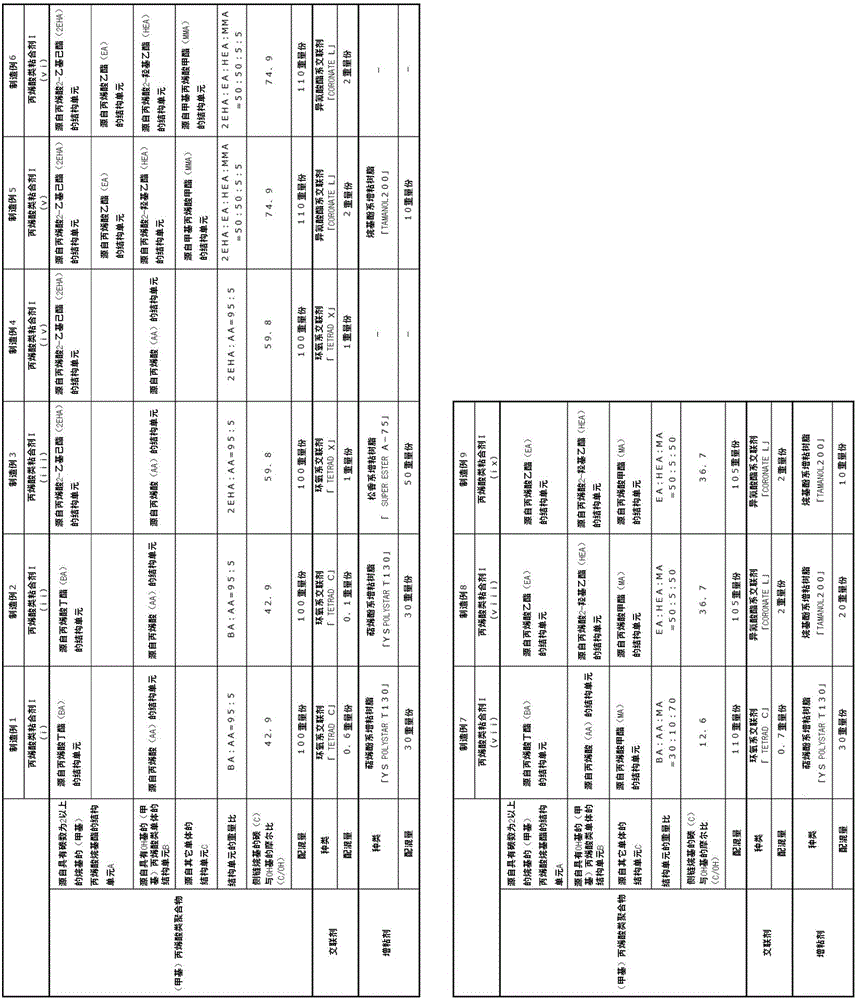

[0131] [Manufacturing Example 1] Preparation of Acrylic Adhesive I(i)

[0132] 100 parts by weight of (meth)acrylic polymer (copolymer of butyl acrylate (BA) and acrylic acid (AA), structural unit derived from BA: structural unit derived from AA (weight ratio)=95:5) 0.6 parts by weight of an epoxy-based crosslinking agent (manufactured by Mitsubishi Gas Chemical Co., Ltd., trade name "TETRAD C") and a terpene-phenolic tackifier resin (manufactured by YASUHARA CHEMICAL CO., LTD., trade name "YS POLYSTAR T130") 30 parts by weight were mixed to prepare an acrylic adhesive I(i).

manufacture example 2~9

[0133] [Production Examples 2-9] Preparation of Acrylic Adhesive I(ii)-(ix)

[0134] Acrylic adhesives I(ii) to (ix) were prepared by mixing the (meth)acrylic polymers, crosslinking agents, and tackifier resins shown in Table 1 in the compounding quantities shown in Table 1.

[0135] TETRAD X: Epoxy-based crosslinking agent; manufactured by Mitsubishi Gas Chemical Co., Ltd., trade name "TETRAD X"

[0136] CORONATE L: Isocyanate-based crosslinking agent; manufactured by Nippon Polyurethane Industry Co., Ltd., trade name "CORONATE L"

[0137] SUPERESTER A-75: Rosin-based tackifier resin; manufactured by Arakawa Chemical Industry Co., Ltd., trade name "SUPERESTER A-75"

[0138] TAMANOL 200: Alkylphenol-based tackifying resin; manufactured by Arakawa Chemical Industry Co., Ltd., trade name "TAMANOL 200"

[0139] Table 1

[0140]

Embodiment 1

[0142] 130.6 parts by weight of the acrylic adhesive I (i) obtained in Production Example 1, 25 parts by weight of heat-expandable microspheres (manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd., trade name "Matsumoto Microsphere F-50D"), and 210 parts by weight of toluene parts were mixed to prepare a composition (i) for forming an adhesive layer.

[0143] The composition (i) for forming an adhesive layer was coated on both sides of a PET film (manufactured by Toray Co., Ltd., trade name "Lumirror S10", thickness: 100 μm) as a base material to form a first film with a thickness of 40 μm. an adhesive layer and a second adhesive layer.

[0144] Through the above operations, a heat-peelable pressure-sensitive adhesive sheet including a first pressure-sensitive adhesive layer (40 μm), a base material (100 μm) and a second pressure-sensitive adhesive layer (40 μm) in this order was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com