Hydrogen peroxide system etching liquid for TFT copper-molybdenum lamination

An etching solution and stacking technology, which is applied in the field of copper-molybdenum laminated film etching of thin film transistors, can solve the problems of difficult rate control, fast copper etching, and large environmental hazards, and achieve small loss of critical size, stable etching angle, and easy reaction The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

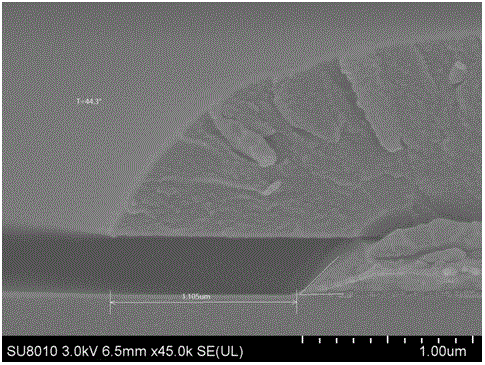

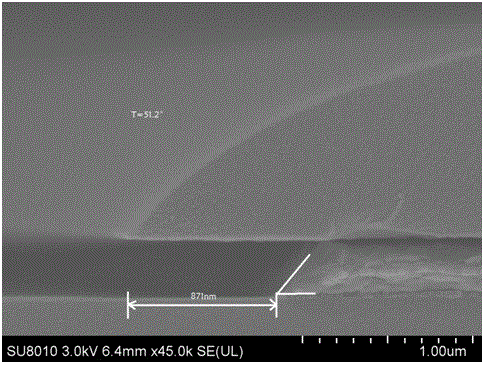

Image

Examples

Embodiment 1

[0037] Example 1 The components and weight percentages of the hydrogen peroxide etching solution used for TFT copper-molybdenum lamination are: 20% hydrogen peroxide, 0.5% sulfuric acid, 1.2% potassium dihydrogen phosphate, 1.5% hydrogen peroxide stabilizer, metal Chelating agent 2%, metal corrosion inhibitor 1% and balance water. The hydrogen peroxide stabilizer is polyacrylamide, the metal chelating agent is iminodiacetic acid, and the metal corrosion inhibitor is imidazole.

Embodiment 2

[0039] Example 2 The components and weight percentages of the hydrogen peroxide-based etching solution used for TFT copper-molybdenum lamination are: 20% hydrogen peroxide, 1% sulfuric acid, 2% potassium phosphate, 1.5% hydrogen peroxide stabilizer, metal chelating agent 2%, metal corrosion inhibitor 1%, and the balance water. The hydrogen peroxide stabilizer is polyacrylamide, the metal chelating agent is iminodiacetic acid, and the metal corrosion inhibitor is imidazole.

Embodiment 3

[0041] Example 3 The components and weight percentages of the hydrogen peroxide-based etching solution used for TFT copper-molybdenum lamination are: 15% hydrogen peroxide, 2% sulfuric acid; 2.5% ammonium phosphate, 1.5% hydrogen peroxide stabilizer, and metal chelating agent 2%, metal corrosion inhibitor 1.5% and the balance water. The hydrogen peroxide stabilizer is polyacrylamide, the metal chelating agent is iminodiacetic acid, and the metal corrosion inhibitor is imidazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com