A kind of preparation method of antimony oxide film

An antimony oxide film and transparent electrode technology, applied in the field of preparation of inorganic functional films, can solve problems such as temperature rise, coarse grains, complex sputtering equipment, etc., and achieve the advantages of avoiding blocking effect, simple preparation method and good application prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

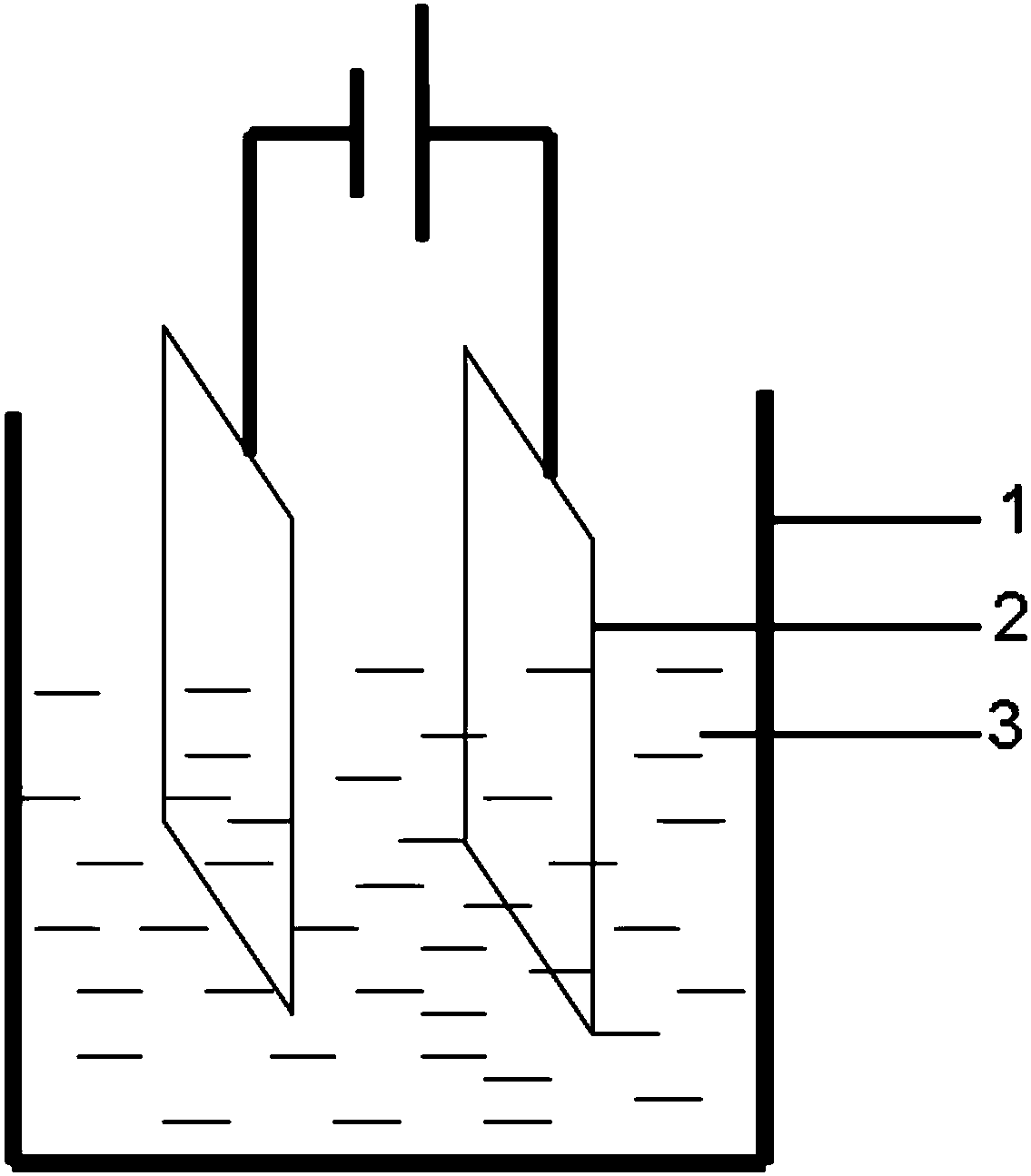

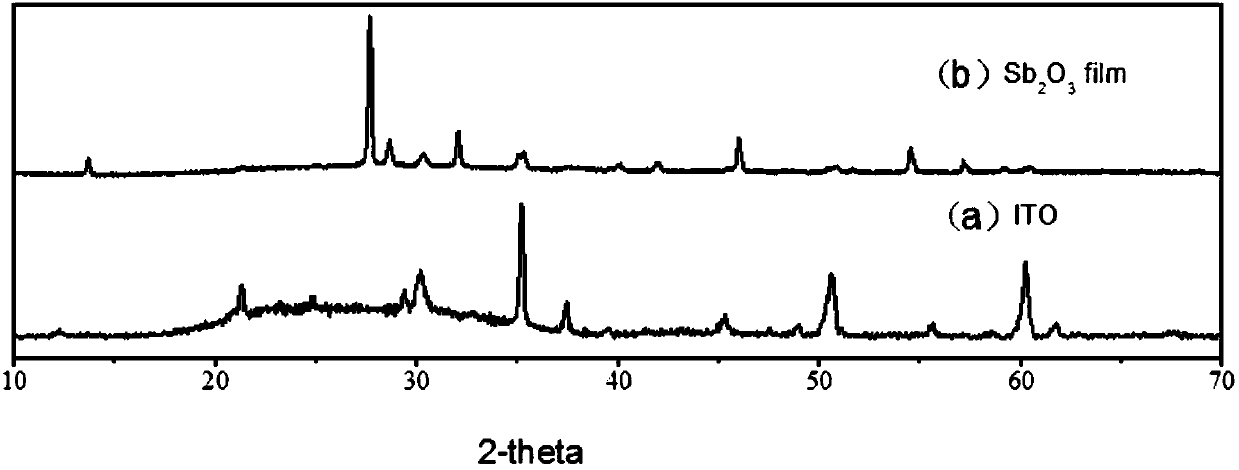

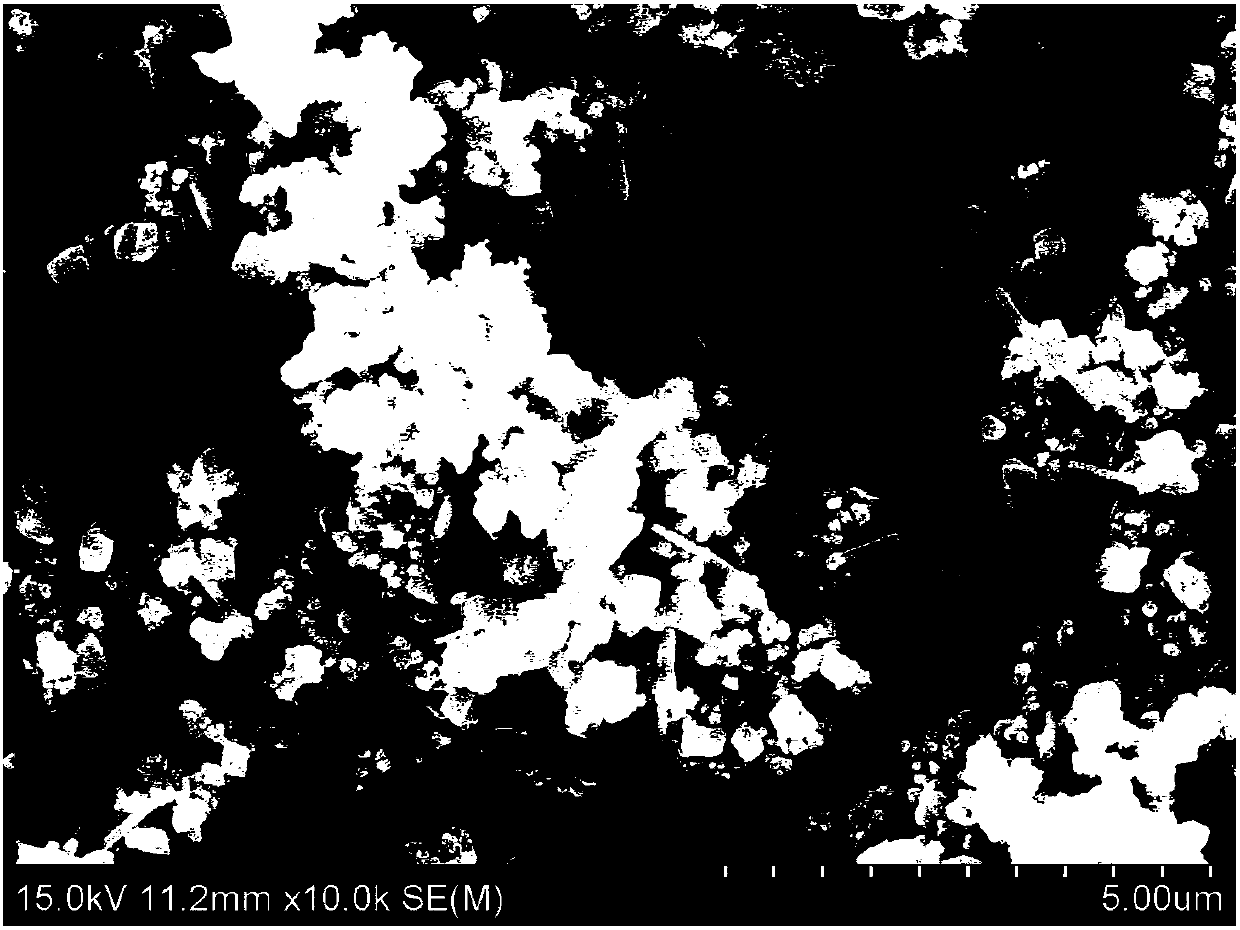

[0024] Conductive glass (ITO) was ultrasonically cleaned in acetone and ethanol solutions for 15 minutes, and then rinsed with deionized water; 0.03gSb 2 S 3 Add to 10ml ethylenediamine and 1ml 1,2-ethanedithiol mixed solvent, stir and dissolve at room temperature to prepare electrodeposition solution; figure 1 As shown, two pieces of conductive glass 2 are used as cathode and anode electrodes, vertically arranged in the electrolytic tank 1 equipped with the above-mentioned electrodeposition solution 3, the electrode surfaces are parallel to each other, and the cathode constant potential electrodeposition is carried out, the voltage is 4V, and the plating time is After the electrodeposition is completed, a layer of uniform and dense film is deposited on the conductive glass. The electrodeposited film is soaked in pure water for 24 hours, then heat-treated at 400°C for 1 minute under nitrogen, and naturally cooled to room temperature to obtain antimony oxide membrane.

[0025...

Embodiment 2

[0028] Conductive glass (FTO) was ultrasonically cleaned in acetone and ethanol solutions for 15 minutes, and then rinsed with deionized water; 0.02gSb 2 S 3 Add it to a mixed solvent of 10ml ethylenediamine and 1ml 1,2-ethanedithiol, stir and dissolve at room temperature to obtain an electrodeposition solution; use two pieces of conductive glass as cathode and anode electrodes, and put them in a vertical arrangement with the above electrodes In the electrolytic tank of the deposition solution, the electrode surfaces are parallel to each other, and the cathode constant potential electrodeposition is carried out, the voltage is 8V, and the electroplating time is 20min. After the electrodeposition is completed, a uniform and dense film is deposited on the conductive glass, and the electrodeposited film Soak in pure water for 10 hours, then heat-treat at 350° C. for 5 minutes under nitrogen, and cool naturally to room temperature to obtain an antimony oxide film.

Embodiment 3

[0030] Conductive glass (AZO) was ultrasonically cleaned in acetone and ethanol solutions for 15 minutes, and then rinsed with deionized water; 0.01gSb 2 S 3 Add it to a mixed solvent of 10ml ethylenediamine and 1ml 1,2-ethanedithiol, stir and dissolve at room temperature to obtain an electrodeposition solution; use two pieces of conductive glass as cathode and anode electrodes, and put them in a vertical arrangement with the above electrodes In the electrolytic tank of the deposition solution, the electrode surfaces are parallel to each other, and the cathode constant potential electrodeposition is carried out, the voltage is 2V, and the electroplating time is 10min. After the electrodeposition is completed, a layer of uniform and dense film is deposited on the conductive glass. The electrodeposited film Soak in pure water for 8 hours, then heat-treat at 300° C. for 10 minutes under nitrogen gas, and cool naturally to room temperature to obtain an antimony oxide film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com