Coating and modifying method for electrode material of lithium ion battery

A technology of lithium-ion batteries and electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as difficulty in industrial mass production, high production costs, and low output, and achieve Reduce lithium consumption, prolong life, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a kind of encapsulation modification method of lithium-ion battery electrode material, and it comprises the following steps:

[0024] (a) Dissolve 0.025g of potassium vinyl trifluoroborate in 20ml of deionized water, and stir evenly to form a solution with a concentration of 1.25mg / ml;

[0025] (b) Add 5g of natural graphite to the above solution, use mechanical stirring to completely soak the graphite in the solution, then continuously stir in a water bath at 70°C, evaporate and remove the water, at this time, potassium vinyl trifluoroborate is deposited on the natural stone the surface of the ink;

[0026] (c) placing the product in step (b) in a vacuum oven and drying at 170° C. for 12 hours to remove residual moisture in step (b), while making the coating layer closely contact with the graphite surface;

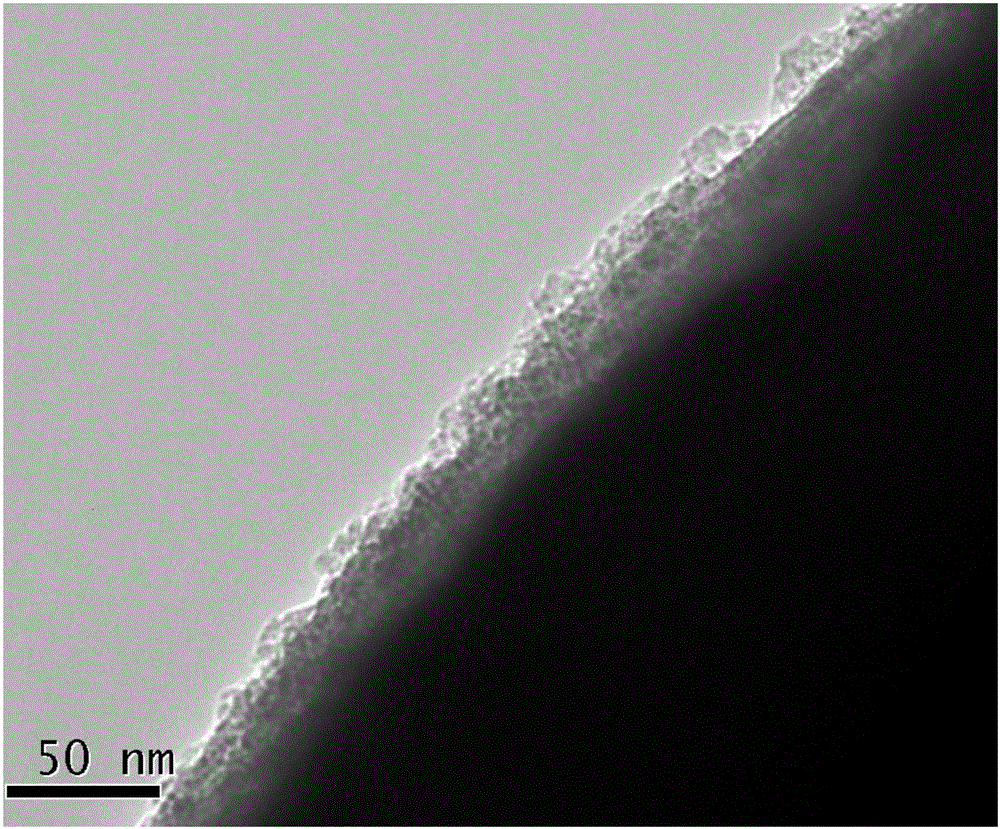

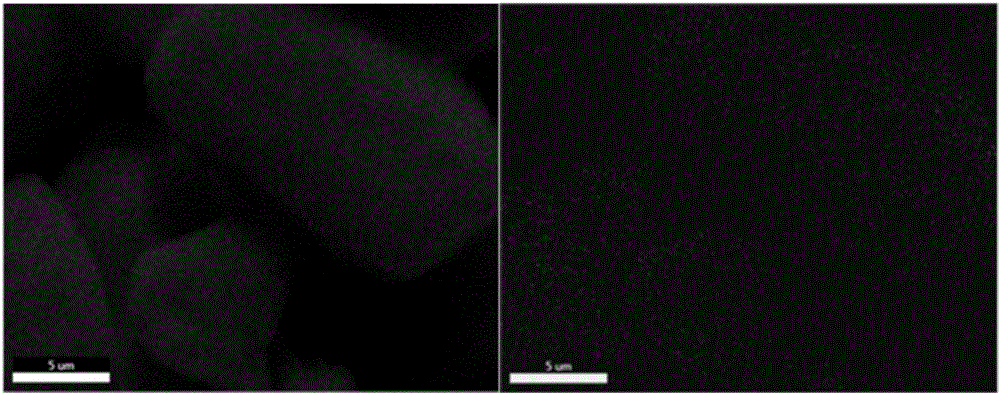

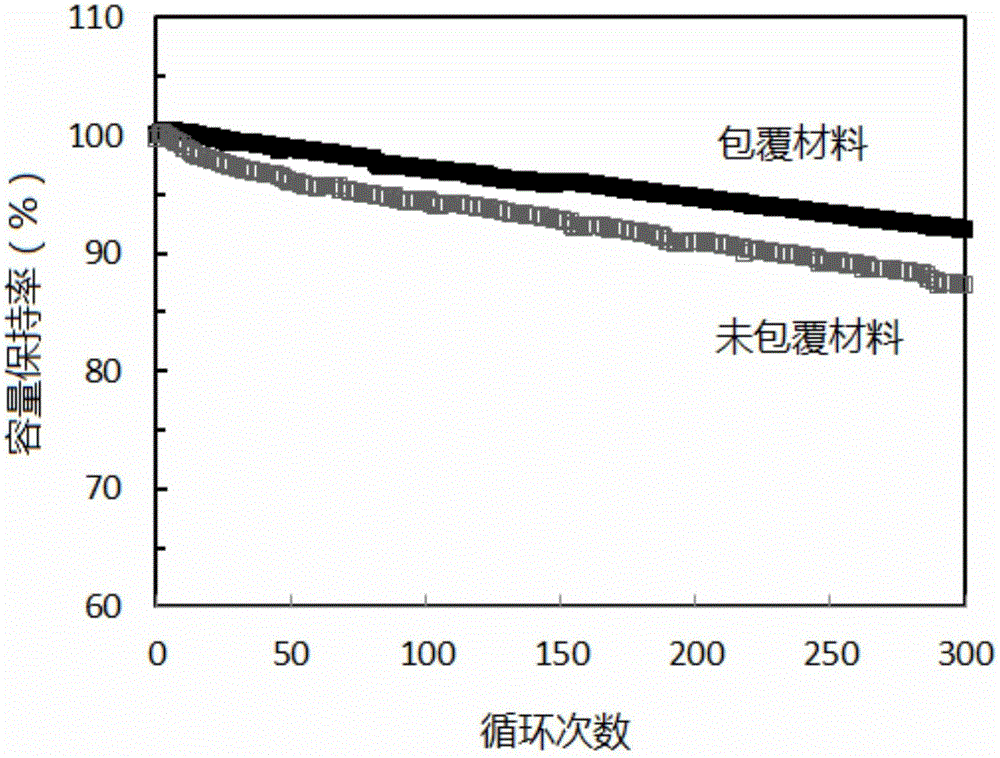

[0027] The obtained SEM image and EDX image are as follows figure 1 and figure 2 As shown, it can be seen that potassium vinyl ...

Embodiment 2

[0029] This embodiment provides a method for coating and modifying lithium-ion battery electrode materials. In 20ml deionized water, stir evenly to form a solution with a concentration of 2.5mg / ml.

Embodiment 3

[0031] This embodiment provides a method for coating and modifying lithium-ion battery electrode materials. In 20ml deionized water, stir evenly to form a solution with a concentration of 2.0mg / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com