Method and device for removing harmful gas through discharging plasmas

A discharge plasma and harmful gas technology, which is applied in the fields of air pollution control and environmental protection, can solve the problems of difficult large-scale application and high energy consumption, and achieve the effect of promoting absorption and degradation and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

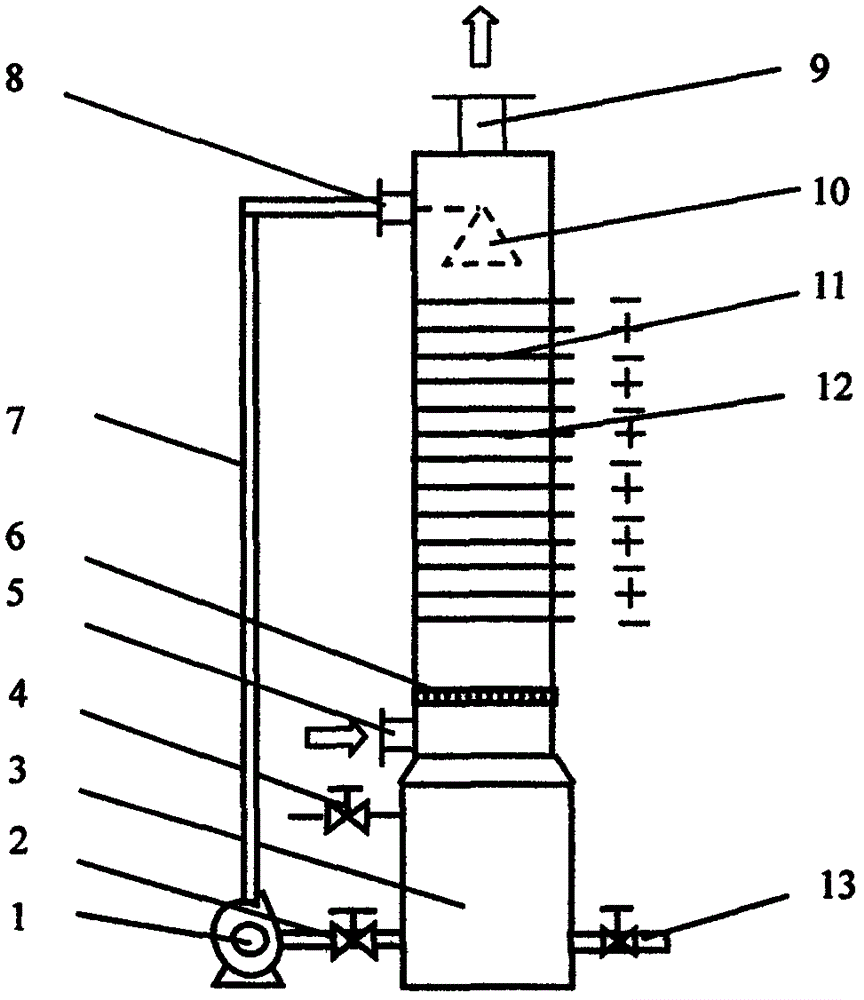

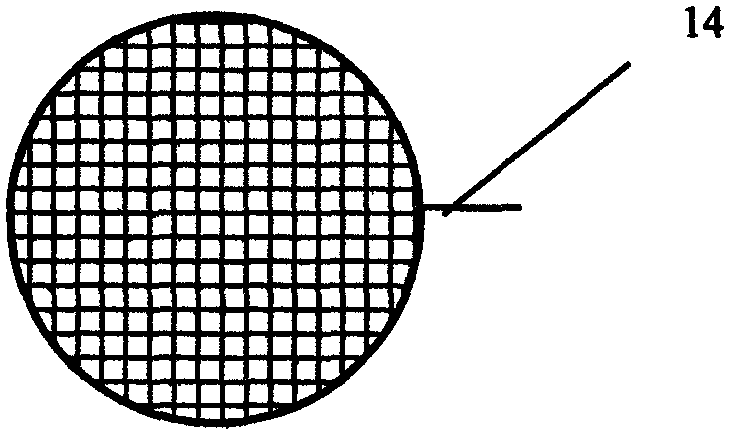

[0017] Embodiment 1: A device for removing harmful gases by discharge plasma according to the present invention such as figure 1 shown. The device is cylindrical, the material of the cylinder is PP, the external dimensions are Φ150mm×1200mm, and it is placed vertically. electrode as figure 2 The disc-shaped mesh electrode, the electrode material is 316L stainless steel, punched and formed, the mesh is rectangular, the electrode size is Φ140mm×2mm, the single hole size is 10mm×10mm, the distance between the electrodes is about 15mm, a total of 12 groups. The electrode power supply methods are DC, pulse and AC, in which the DC and AC voltages are about 6kV, the AC frequency is about 50Hz, the pulse voltage is about 8kV, and the pulse frequency is about 30Hz. The negative electrode is grounded when the DC and pulse power supply is used, and the power supply is about 50Hz. 100W.

[0018] The treatment process is to enter the gas-liquid contact discharge plasma area of the de...

Embodiment 2

[0023] Example 2: The electrode material is a titanium-based ruthenium dioxide composite electrode, and the gas flow rate is about 2m 3 / h. The residence time of the gas flow in the gas-liquid contact discharge plasma area is about 5s, the spray volume of the absorption liquid is about 25L / h, and the spray frequency is about 1 time / s. The distance between electrodes is about 30mm. The electrode power supply mode is pulse, the pulse voltage is about 15kV, and the pulse frequency is about 50Hz. Other experimental conditions are the same as in Example 1.

[0024] The experimental results are shown in Table 2.

[0025] Table 2 Harmful substance removal effect

[0026] Harmful substances

Embodiment 3

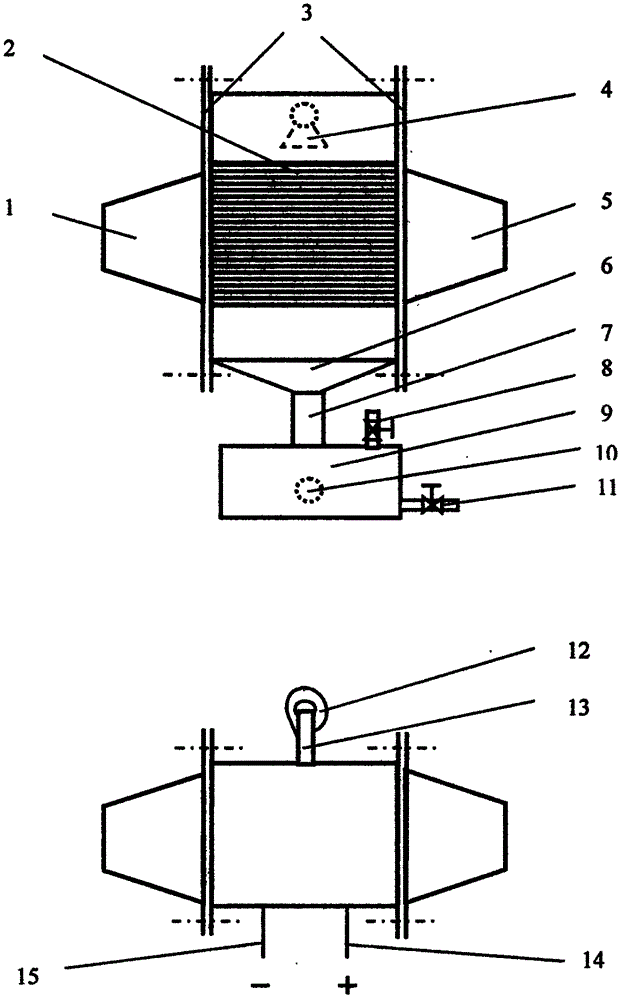

[0027] Embodiment 3: A device for removing harmful gases by discharge plasma according to the present invention such as image 3 shown. The main body of the device is in the shape of a cuboid, made of PP, and the main body dimensions are 200mm×150×450mm, placed horizontally. The electrode is a rectangular mesh electrode, the electrode material is 316L stainless steel, punched and formed, the mesh is rectangular, the overall size is 180mm×130×2mm, the single hole size is 10mm×10mm, the distance between the electrodes is about 10mm, a total of 12 groups, placed horizontally . The electrode power supply mode is DC, the voltage is about 4kV, and the power supply is about 100W.

[0028] The treatment process is to enter the gas-liquid contact discharge plasma area 2 of the device through the gas inlet 1 through the gas distributor 3 (inlet) into the air flow containing the harmful gas, and connect the positive electrode 14 of the mesh electrode with alternating positive and negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com