Hydrothermal method for preparing HfO2 nano-particles

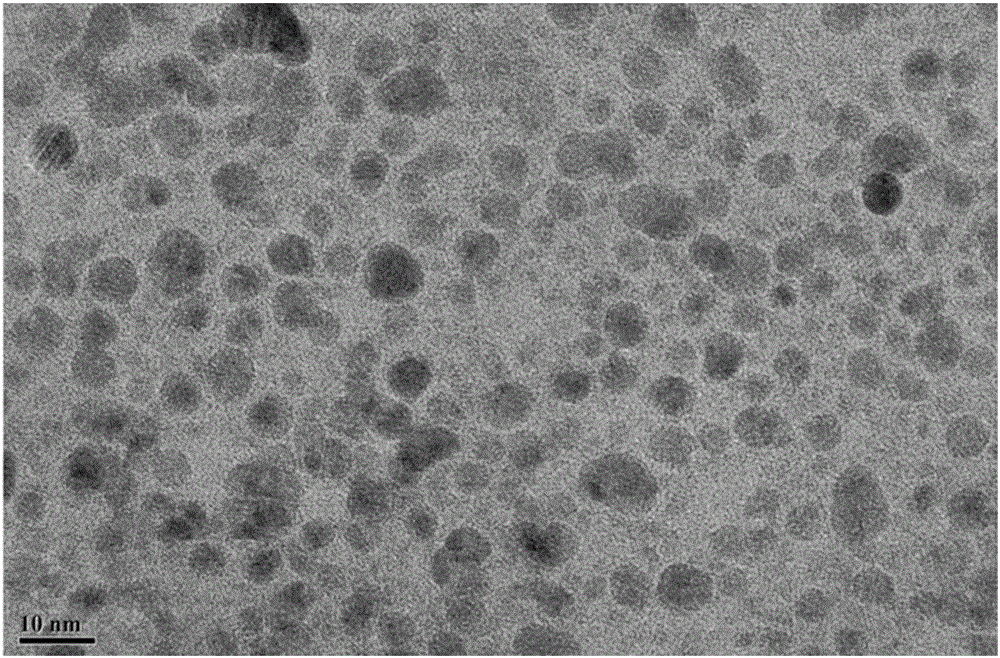

A nanoparticle and hydrothermal technology, which is applied in the field of preparation of HfO2 nanomaterials, can solve the problems of lack of performance powder, large particle size, low doping degree, etc., and achieves good application prospects, narrow particle size distribution, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

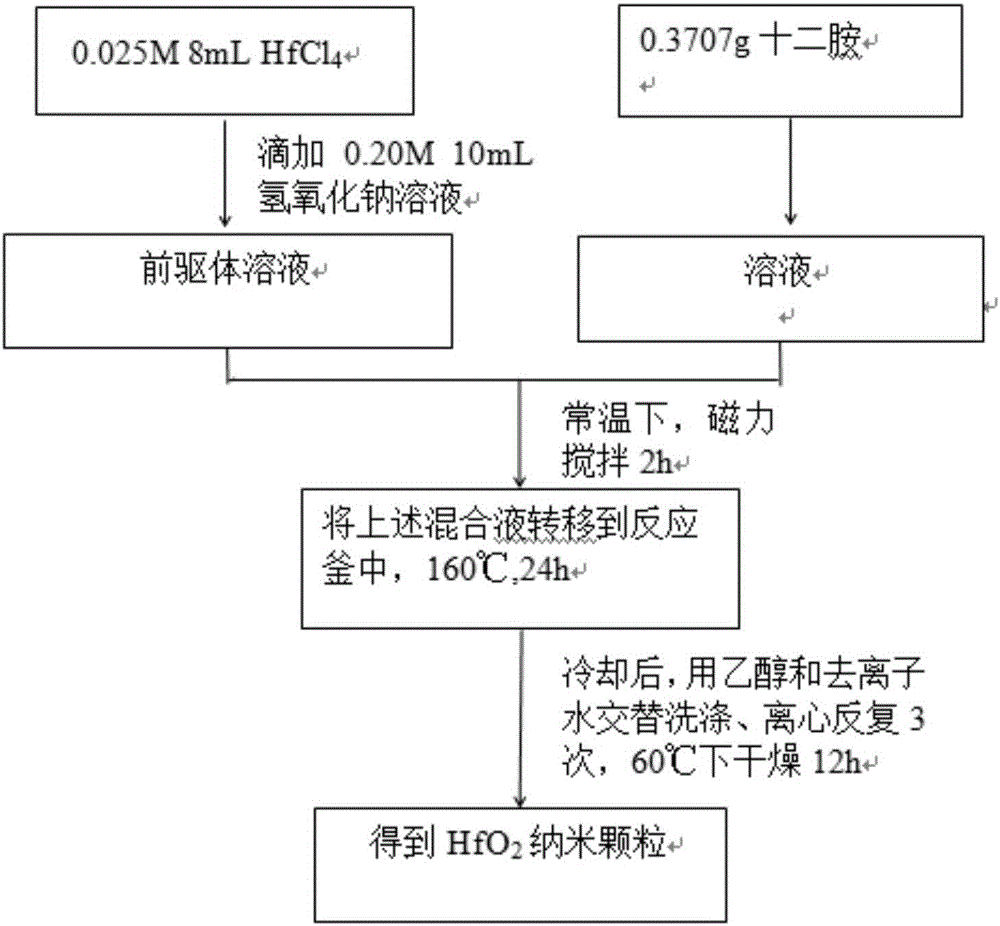

[0028] 1. Weigh 0.16g of hafnium tetrachloride and dissolve it in 8mL of deionized water to obtain hafnium oxychloride solution;

[0029] 2. Weigh 0.08g of sodium hydroxide, dissolve it in 10mL of deionized water at room temperature, and add the sodium hydroxide solution to the above solution with a rubber dropper to obtain a precursor solution;

[0030] 3. Weigh 0.3707g of dodecylamine, dissolve it in 2mL of ethanol, mix the obtained solution with the above precursor solution, and stir magnetically at room temperature for 2 hours to obtain a uniformly mixed solution;

[0031] 4. Transfer the mixed solution into a 100ml polytetrafluoroethylene-lined stainless steel high-pressure hydrothermal kettle, keep it warm at 160°C for 24 hours, wait for the hydrothermal kettle to cool down to room temperature, and centrifuge the obtained mixed solution to obtain a precipitate, deionized water and Wash with absolute ethanol three times respectively, and dry in an oven at 60°C for 12 hour...

Embodiment 2

[0033] 1. Weigh 0.16g of hafnium tetrachloride and dissolve it in 10mL of deionized water to obtain hafnium oxychloride solution;

[0034] 2. Weigh 0.08g of sodium hydroxide, dissolve it in 10mL of deionized water at room temperature, and add the sodium hydroxide solution to the above solution with a rubber dropper to obtain a precursor solution;

[0035] 3. Transfer the mixed solution into a 100ml polytetrafluoroethylene-lined stainless steel high-pressure hydrothermal kettle, keep it warm at 160°C for 24 hours, wait for the hydrothermal kettle to cool down to room temperature, and centrifuge the obtained mixed solution to obtain a precipitate, deionized water and Wash with absolute ethanol three times respectively, and dry in an oven at 60°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com