Zero emission recycling process for treating power plant desulfurization high-salinity high-hardness wastewater

A zero-emission, high-hardness technology, used in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as corrosion-prone equipment, shortened slag furnace life, and easy scaling. , achieve the effect of reducing the total evaporation, realizing resource utilization, and good effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with content of the present invention is described further:

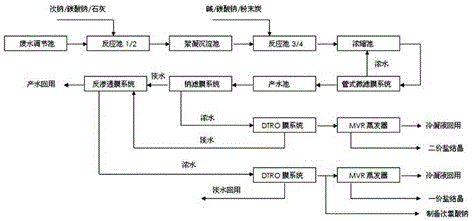

[0025] As shown in the figure is the zero-discharge reuse process flow chart for the treatment of desulfurization, high-salt and high-hardness wastewater from power plants.

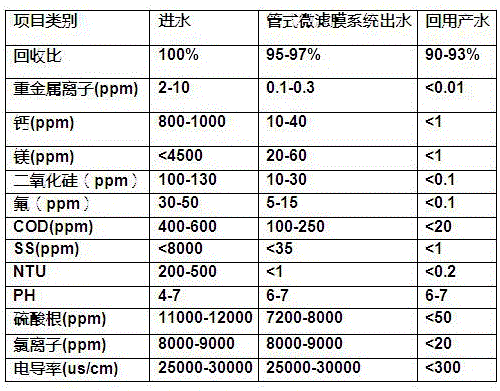

[0026] Tubular microfiltration membrane equipment is used to efficiently intercept the reacted particles, calcium carbonate, magnesium hydroxide and other pollutants, and realize that after the high hardness wastewater is treated by Duraflow tubular microfiltration membrane equipment, calcium and magnesium ions are reduced to below 30ppm .

[0027] Tubular microfiltration equipment is a high-efficiency solid-liquid separation membrane system. The wastewater containing granular sludge is pumped into the membrane system for cement separation through the circulation pump. The tubular microfiltration membrane equipment includes: concentration pool, circulation pump, membrane support, pipe Type microfiltration membrane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com