Production method of fertilizer containing sugar alcohol chelated medium elements

A technology for chelating medium elements and production methods, which can be applied to liquid fertilizers, fertilizer mixtures, nitrate fertilizers, etc., and can solve problems such as uneven nutrition, low utilization rate, and enrichment of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

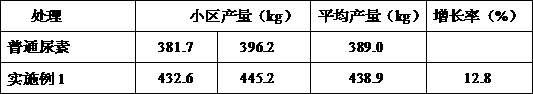

Embodiment 1

[0017] Add calcium nitrate tetrahydrate, magnesium nitrate, sorbitol, erythritol, mannitol, water and glycerol into the reaction kettle in a mass ratio of 25:13:34:5:20:2:1, at 80°C Carry out the chelation reaction until the calcium nitrate tetrahydrate and magnesium nitrate are completely dissolved to obtain the sugar alcohol chelated middle element. The sugar alcohol chelated middle element is added to the urea production urea, and the sugar alcohol chelates the middle element. The mass ratio of urea to urea is 0.5:99.5. After spraying, drying, cooling and sieving, the chelated urea containing sugar alcohol is obtained.

Embodiment 2

[0019] Add calcium nitrate tetrahydrate, magnesium nitrate, sorbitol, erythritol, mannitol, water and glycerol into the reaction kettle in a mass ratio of 25:13:34:5:20:2:1, at 80°C Carry out the chelation reaction, until the calcium nitrate tetrahydrate and magnesium nitrate are completely dissolved, the sugar alcohol chelated middle element is obtained, and the sugar alcohol chelated middle element is added to the granulation drum of the compound fertilizer and combined with nitrogen fertilizer, phosphate fertilizer and potassium fertilizer Mixing and granulating, the mass ratio of sugar alcohol chelated middle element, nitrogen fertilizer, phosphate fertilizer and potash fertilizer is 5:20:45:30, after drying, cooling and sieving, the compound containing sugar alcohol chelated middle element is obtained fat.

Embodiment 3

[0021] Add calcium nitrate tetrahydrate, magnesium nitrate, sorbitol, erythritol, mannitol, water and glycerol into the reaction kettle in a mass ratio of 25:13:34:5:20:2:1, at 80°C Carry out the chelation reaction, until the calcium nitrate tetrahydrate and magnesium nitrate are completely dissolved, the sugar alcohol chelated middle element is obtained, and the sugar alcohol chelated middle element is added to the liquid fertilizer, and the sugar alcohol chelates the middle element and the liquid fertilizer. The mass ratio is 45:55, and after mixing evenly, a liquid fertilizer containing sugar alcohol chelated medium elements is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com