Method for lanthanum phosphate coated lithium ion battery cathode material nickel cobalt lithium manganate

A nickel-cobalt lithium manganese oxide and ion battery technology, which can be applied to battery electrodes, secondary batteries, circuits, etc., and can solve the problems of reduced cycle performance and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 0.7388g (0.01mol) of lithium carbonate, 0.3879g (0.9mmol) of lanthanum nitrate hexahydrate, 1.4499g (0.9mmol) of ammonium dihydrogen phosphate and 1.7427g (0.019mol) of Ni 0.5 co 0.2 mn 0.3 (OH) 2 Ternary material precursor, add the ternary precursor, lithium carbonate, lanthanum salt, and phosphate into the high-speed mixer, stir at 500rpm for 4h to obtain a uniform sample;

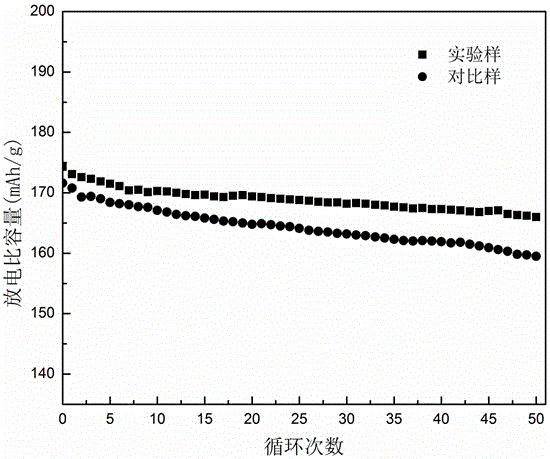

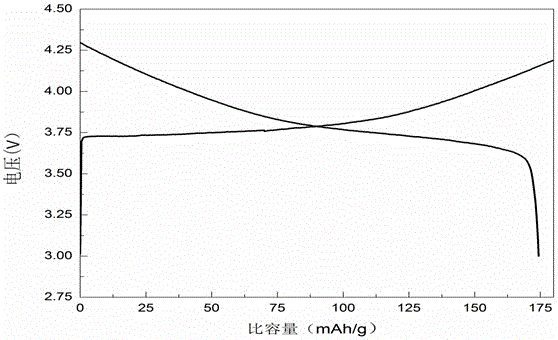

[0025] (2) Heat and sinter the obtained sample at 750°C in the air for 20h, keep it warm for 10h after sintering, and obtain the modified nickel-cobalt lithium manganate ternary positive electrode material after cooling, that is, LaPO 4 Coated lithium-ion battery positive electrode material nickel cobalt lithium manganese oxide (lithium ion battery positive electrode material nickel cobalt lithium manganese oxide element composition is LiNi 0.5 co 0.2 mn 0.3 o 2 ). where LaPO 4 The weight accounts for the total weight of nickel cobalt lithium manganese oxide, the positive electro...

Embodiment 2

[0028] (1) Weigh 0.7388g (0.01mol) of lithium carbonate, 0.1552g (0.4mmol) of lanthanum acetate tetrahydrate, 0.4392g (0.04mmol) of diammonium hydrogen phosphate and 1.8398g (0.02mol) of Ni 0.6 co 0.2 mn 0.2 (OH) 2 Ternary material precursor, add the ternary precursor, lithium carbonate, lanthanum salt, and diammonium hydrogen phosphate into a high-speed mixer, and stir at 2000rpm for 1 hour to obtain a uniform sample;

[0029] (2) Heat and sinter the obtained sample at 1200°C in the air for 6h, keep it warm for 6h after sintering, and obtain the modified nickel-cobalt lithium manganate ternary positive electrode material after cooling, that is, LaPO 4 Coating lithium-ion battery positive electrode material nickel cobalt lithium manganese oxide, (the elemental composition of lithium ion battery positive electrode material nickel cobalt lithium manganese oxide is LiNi 0.6 co 0.2 mn 0.2 o 2 ) where LaPO 4 The weight accounts for the total weight of nickel cobalt lithium m...

Embodiment 3

[0032](1) Weigh 0.2394g (0.01mol) of lithium hydroxide, 0.006g (0.2mmol) of lanthanum nitrate hexahydrate, 0.0245g (0.2mmol) of ammonium dihydrogen phosphate and 0.869g (0.009mol) of Ni 0.8 co 0.1 mn 0.1 (OH) 2 Ternary material precursor, add the ternary precursor, lithium hydroxide, lanthanum salt, and ammonium dihydrogen phosphate into a high-speed mixer, and stir at 1200rpm for 3 hours to obtain a uniform sample;

[0033] (2) The obtained sample was heated and sintered at 1000°C for 12 hours in a pure oxygen atmosphere, kept for 5 hours after sintering, and the modified nickel-cobalt lithium manganese oxide ternary positive electrode material was obtained after cooling, that is, LaPO 4 Coating lithium-ion battery positive electrode material nickel cobalt lithium manganese oxide, (the elemental composition of lithium ion battery positive electrode material nickel cobalt lithium manganese oxide is LiNi 0.8 co 0.1 mn 0.1 o 2 ) where LaPO 4 The weight accounts for the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com