Absorbable antibacterial hemostatic microsphere, preparation method and application thereof

A technology of microspheres and lysozyme, which is applied in the fields of application, pharmaceutical formulation, and medical science, can solve the problems of unsuitable hemostatic powder, difficult to degrade and absorb, etc., and achieve the effects of long storage time, convenient use, and fast degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

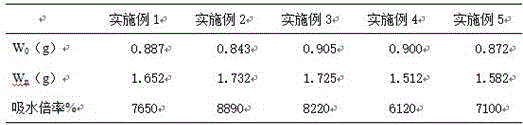

Embodiment 1

[0036] 1. Preparation of matrix solution: Add 1.5 g of sodium alginate, 0.5 g of carboxymethyl chitosan and 0.025 g of gelatin into 100 ml of water and dissolve to make a matrix solution; 2. Mixing of materials: 250 ml of liquid paraffin and 18 ml of spit Mix at 80°C, add matrix solution, and 10 ml of 2% w / w calcium chloride, accompanied by rapid stirring, to carry out cross-linking reaction to prepare microspheres. 3. Refining: After the material liquid is separated, pour out the upper oil phase, discard it, add 500ml of absolute ethanol to the lower liquid, stir, remove the supernatant, and repeat washing 2 to 3 times. Suction filter, add 30 ml of distilled water to dilute and spray dry to obtain microspheres of about 5-60 μm. Add 0.01 g of lysozyme to the microspheres, blend with air blowing, vacuum dry, aseptically treat and seal the package.

Embodiment 2

[0038] 1. Preparation of matrix solution: Add 1.5 g sodium alginate, 0.5 g carboxymethyl chitosan and 0.025 g gelatin to 100 ml water to dissolve to make matrix solution; 2. Material mixing: 100 g fatty acid and 18 ml Tween Mix at 80, add matrix solution, and 10 ml of 2% w / w calcium chloride, accompanied by rapid stirring, to carry out cross-linking reaction to prepare microspheres. 3. Refining: After the material liquid is separated, pour out the upper oil phase, discard it, add 500ml of absolute ethanol to the lower liquid, stir, remove the supernatant, and repeat washing 2 to 3 times. Suction filtration, adding 30 ml of distilled water to dilute and spray-dry to obtain microspheres of about 5-60 μm, vacuum-dried, aseptically treated, and then sealed and packaged (no lysozyme, blank control group).

Embodiment 3

[0040] 1. Preparation of matrix solution: Add 1.5 g of sodium alginate, 0.5 g of carboxymethyl chitosan and 0.025 g of gelatin to 100 ml of water and dissolve to make a matrix solution; 2. Mixing of materials: 200 ml of castor oil and 18 ml of spit Mix at 80°C, add matrix solution, and 10 ml of 2% w / w calcium chloride, accompanied by rapid stirring, to carry out cross-linking reaction to prepare microspheres. 3. Refining: After the material liquid is separated, pour out the upper oil phase, discard it, add 500ml of absolute ethanol to the lower liquid, stir, remove the supernatant, and repeat washing 2 to 3 times. Suction filter, add 50 ml of 5% ethanol to dilute and spray dry to obtain microspheres of about 5-60 μm. Add 0.01 g of lysozyme to the microspheres, blend with air blowing, vacuum dry, aseptically treat and seal the package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com