Titanium dioxide nanotube/hydroxyapatite composite coating used for medical porous titanium and preparation method of titanium dioxide nanotube/hydroxyapatite composite coating

A technology of hydroxyapatite and titanium dioxide, which is applied in the fields of coating, medical science, tissue regeneration, etc., can solve problems such as thermal expansion coefficient mismatch, decrease in bonding strength, and failure of implants, and achieve strong interface bonding and improve bonding Strength, bioactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

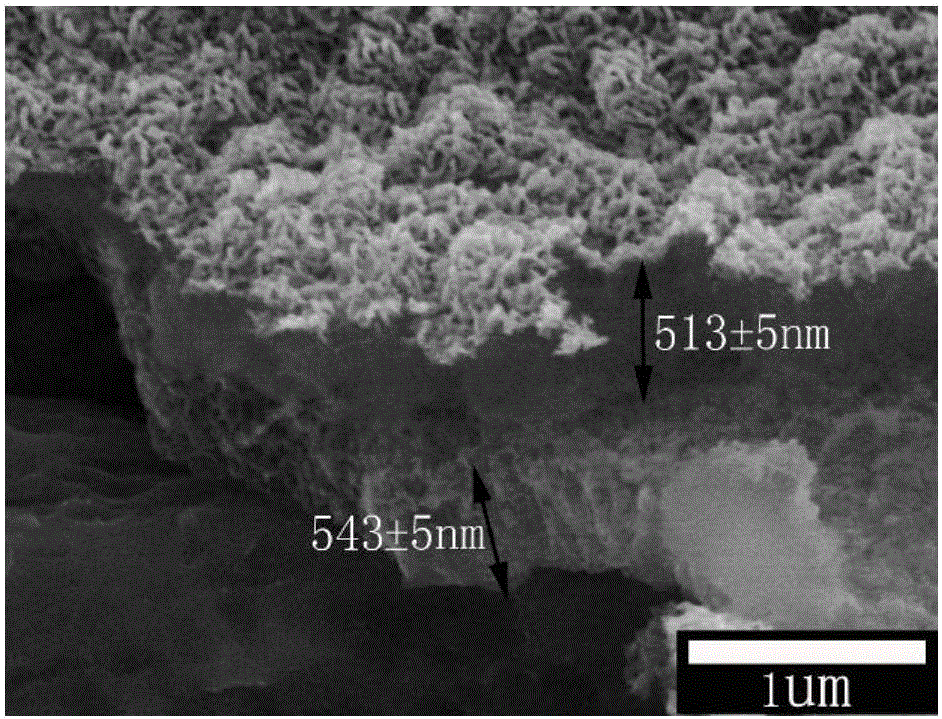

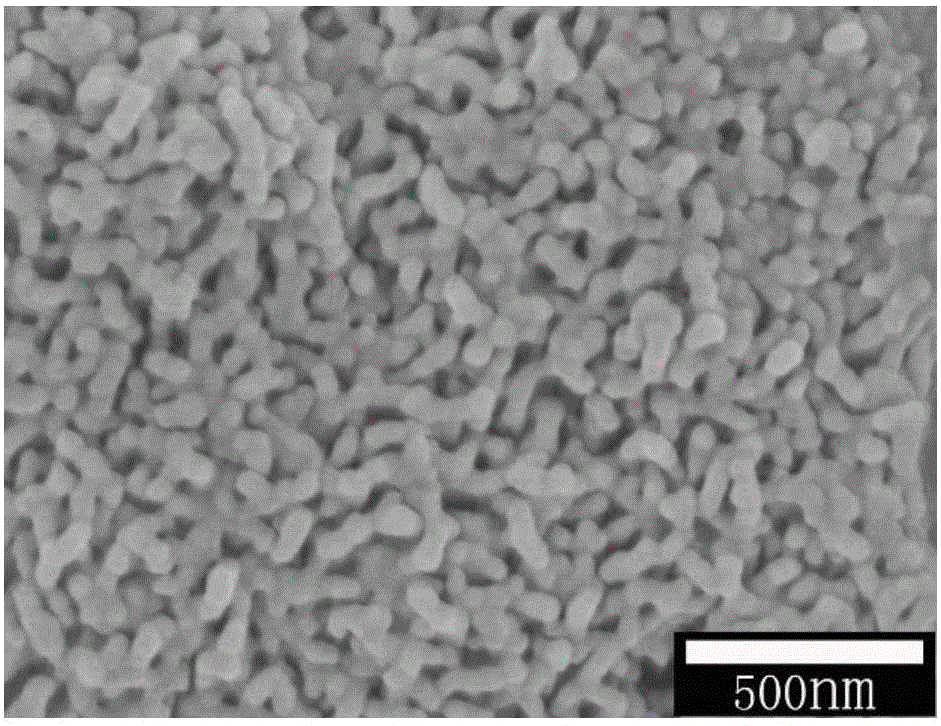

[0030] (1) The size is 10×10×1mm 3 The porous titanium is used as the matrix, and the sample is subjected to 360 # 、600 # , 800 # 、1000 # , 1200 # Water sandpaper was polished in turn until the surface was smooth, and the polished samples were ultrasonically cleaned in deionized water, ethanol, and acetone solutions for 5 minutes. Dry at room temperature. Place it in 0.3M NH 4 In the glycerol / water (1:1vol.%) electrolyte of F, set the anodic oxidation voltage to 15V, and the oxidation time to 1h, prepare titanium dioxide nanotubes in the porous pure titanium restricted network structure, and after the oxidation is completed, the sample is placed in ethanol solution Ultrasonic cleaning in medium and air dry naturally.

[0031] (2) After the above sample is cleaned, it is vertically immersed in phosphate simulated body fluid to grow, and the simulated body fluid is composed of NaCl, KCl, CaCl 2 , NaHCO 3 , MgCl 2 , MgSO 4 ·7H 2 O, C 6 h 12 o 6 , KH 2 PO 4 , Na ...

Embodiment 2

[0034] (1) The size is 10×10×1mm 3 The porous titanium is used as the matrix, and the sample is subjected to 360 # 、600 #, 800 # 、1000 # , 1200 # Water sandpaper was polished in turn until the surface was smooth, and the polished samples were ultrasonically cleaned in deionized water, ethanol, and acetone solutions for 6 minutes. Dry at room temperature. Place it in 0.2M NH 4 In the glycerol / water (1:1vol.%) electrolyte solution of F, set the anodic oxidation voltage to 2V, and the oxidation time to 2h, prepare titanium dioxide nanotubes in the porous titanium alloy restricted network structure, and after the oxidation is completed, the sample is placed in ethanol solution Ultrasonic cleaning in medium and air dry naturally.

[0035] (2) After the above sample is cleaned, it is vertically immersed in phosphate simulated body fluid to grow, and the simulated body fluid is composed of NaCl, KCl, CaCl 2 , NaHCO 3 , MgCl 2 , MgSO 4 ·7H 2 O, C 6 h 12 o 6 , KH 2 PO ...

Embodiment 3

[0038] (1) The size is 10×10×1mm 3 The porous titanium is used as the matrix, and the sample is subjected to 360 # 、600 # , 800 # 、1000 # , 1200 # Water sandpaper was polished in turn until the surface was smooth, and the polished samples were ultrasonically cleaned in deionized water, ethanol, and acetone solutions for 5 minutes. Dry at room temperature. Place it in 0.4M NH 4 In the glycerol / water (1:1vol.%) electrolyte of F, set the anodic oxidation voltage to 20V, and the oxidation time to 0.5h, prepare titanium dioxide nanotubes in the porous titanium alloy restricted network structure, and after the oxidation is completed, the sample is placed in ethanol The solution was ultrasonically cleaned and air-dried naturally.

[0039] (2) After the above sample is cleaned, it is vertically immersed in phosphate simulated body fluid to grow, and the simulated body fluid is composed of NaCl, KCl, CaCl 2 , NaHCO 3 , MgCl 2 , MgSO 4 ·7H 2 O, C 6 h 12 o 6 , KH 2 PO 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com